Minimally-invasive-surgical-robot four-dimensional force sensor based on fiber gratings

A technology of surgical robot and force sensor, which is applied in the direction of measuring the change force of the optical properties of the material when it is stressed, to achieve the effects of reduced coupling, low cost and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

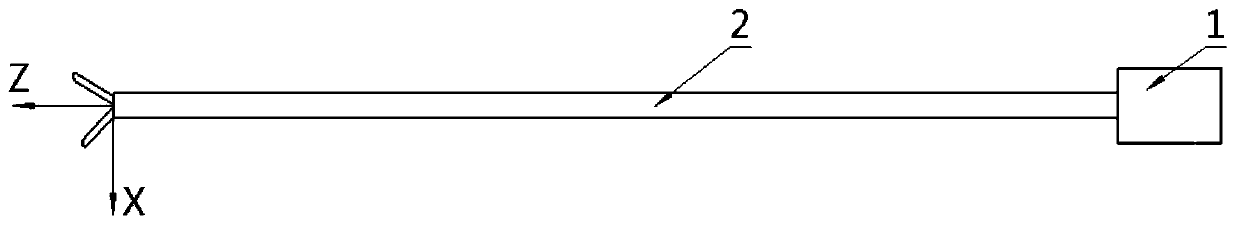

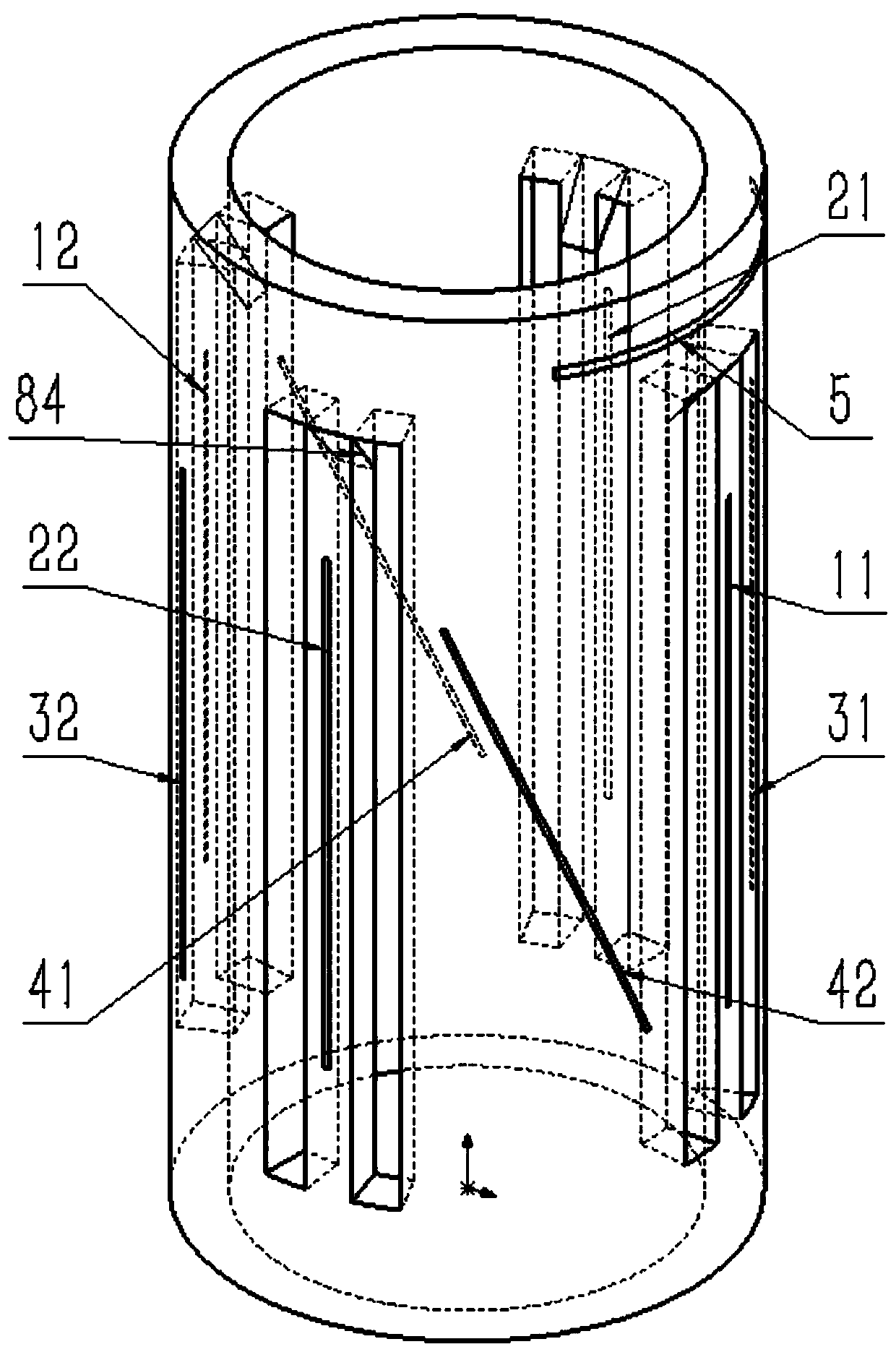

[0021] The invention intends to measure in real time the force on the end effector of the manipulator in the directions of three degrees of freedom and the torque along the axial direction. Before the operation, the manipulator was inserted into the abdominal cavity through the trocar sheath fixed on the patient's abdominal wall; in order to avoid the influence of the contact between the manipulator and the trocar sheath on the force and moment measurement, the fiber Bragg grating four-dimensional force sensor was placed on the hollow glass The position on the surface of the fiber round rod close to the end effector can more accurately measure the contact force and moment between the end effector of the manipulator and the patient's visceral tissue during the operation.

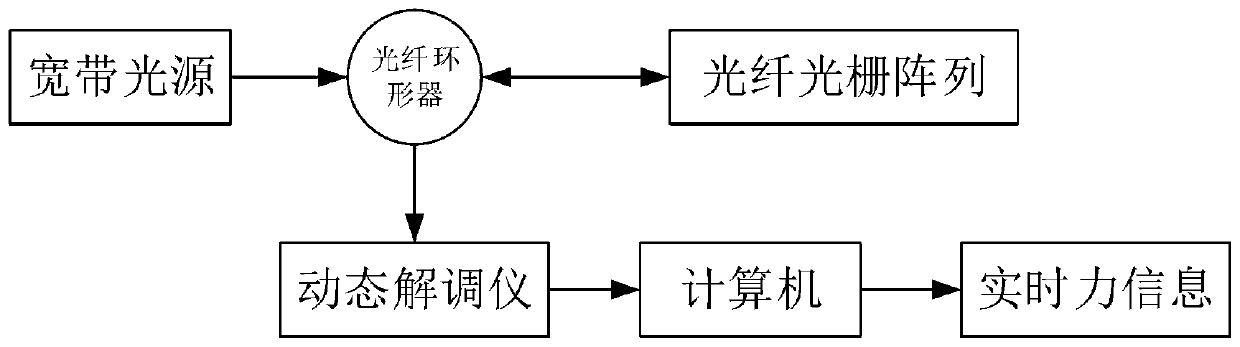

[0022] The four-dimensional force sensor for a minimally invasive surgical robot provided by the present invention is mainly composed of nine fiber gratings, and the layout of the nine fiber gratings is as fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com