Nutrient release testing method of boron-containing polymer slow-release fertilizer

A test method and technology for slow-release fertilizers, which are applied in the direction of removing certain components and weighing, etc., can solve the problems of limited popularization and application, difficult degradation of coating materials, and high prices of slow-release fertilizers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

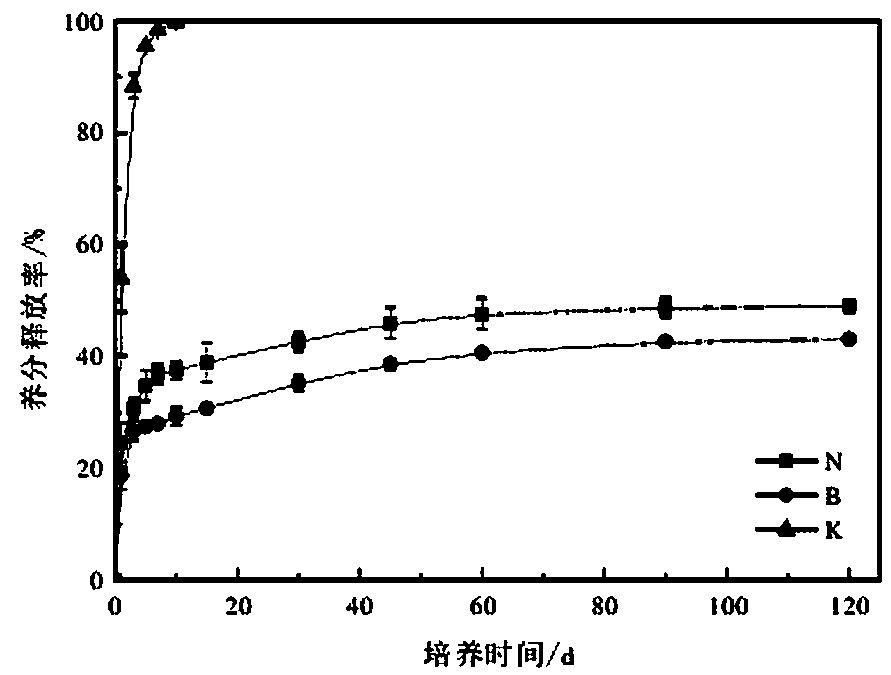

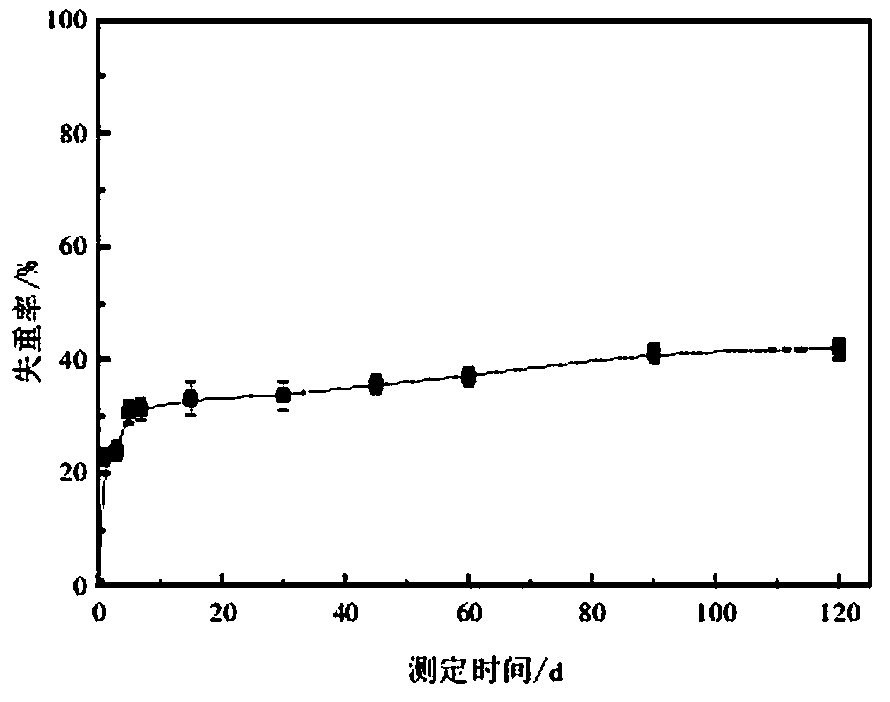

[0023] A kind of nutrient release testing method of boron-containing macromolecule slow-release fertilizer, comprises the following steps,

[0024] Include the following steps,

[0025] At 25°C, weigh 5.0 g of boron-containing polymer slow-release fertilizers, put them into polyethylene bottles filled with 100 mL of deionized water, and place them on the 1st, 3rd, 5th, 7th, 15th, 30th, and Samples were taken and tested on days 45, 60, 90, and 120. Each sample was filtered with a No. 4 sand core funnel, the filtered fertilizer was returned to the original bottle, and 100 mL of fresh deionized water was added to continue the cultivation. Each treatment was repeated 3 times.

[0026] Sampling analysis specifically includes the following test analysis,

[0027] (1) Determination of ammonium nitrogen: Take 5g of fresh soil sample, add 30mL KCl solution for extraction, absorb 5mL of extraction solution, add 5mL of phenol solution and 5mL of sodium hypochlorite solution, place at ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com