Preparation technology of boron-containing high molecular slow-release fertilizer

A preparation process and polymer technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems that the fertilizer effect of trace elements cannot be exerted normally, the coating material is difficult to degrade, and the price is expensive.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A preparation process for boron-containing polymer slow-release fertilizer, comprising the following steps,

[0019] (1) Add 2.06g of boric acid and 1.87g of potassium hydroxide into a round bottom flask, react at 90°C for 3h to obtain product A, and cool down the system for later use;

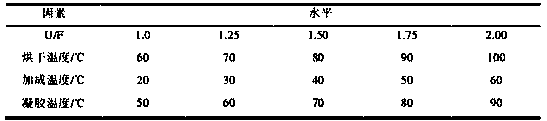

[0020] (2) Add a certain proportion of urea and formaldehyde into the three-necked flask, adjust the pH of the system to 8 with 5% KOH aqueous solution, stir and react at T1 temperature for 80 minutes (addition reaction), adjust the temperature of the water bath to 60°C and continue the reaction for 40 minutes (polycondensation reaction); add to the system of step (1), adjust the temperature to T3 (gel temperature), react under stirring until the system starts to become viscous and stop the reaction, and dry at T4 temperature after granulation.

[0021] The addition reaction in step (2) is that formaldehyde and urea react under alkaline conditions to generate methylol urea:

[0022] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com