Biodegradable organic polymer nitrogen fertilizer and preparation method thereof

A technology of organic polymers and nitrogen fertilizers, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of reduced nutrient content, pollution, and increased production costs of chemical fertilizers, and achieve improved utilization, reduced fixed amounts, and excellent slow and controlled release. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Biodegradable organic polymer nitrogen fertilizer, the preparation method of which is:

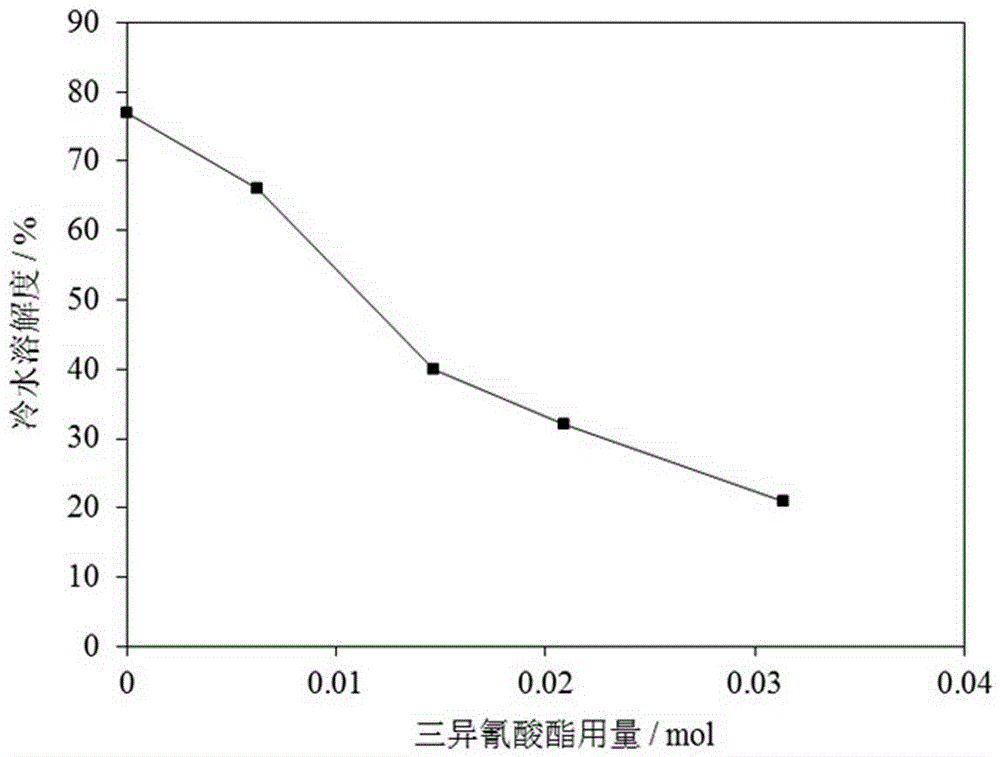

[0037] Add 1.00mol methyl carbamate, 0.10mol urea and 0.06mol catalyst potassium carbonate to the reaction vessel, react at 160°C for 6h, then add 0.33mol crosslinking agent triisocyanate, stir, when the reaction solution becomes viscous, Granulate and dry to obtain biodegradable organic high molecular nitrogen fertilizer.

[0038] The cold water solubility of the obtained biodegradable organic polymer nitrogen fertilizer is 2%, and the hot water solubility is 32%.

Embodiment 2

[0040] Biodegradable organic polymer nitrogen fertilizer, the preparation method of which is:

[0041] Add 1.00mol methyl carbamate, 0.10mol urea and 0.06mol catalyst potassium carbonate to the reaction vessel, react at 160°C for 6h, then add 0.026mol crosslinking agent triisocyanate, stir, when the reaction solution becomes viscous, Granulate and dry to obtain biodegradable organic high molecular nitrogen fertilizer.

[0042] The nitrogen content of the obtained biodegradable organic polymer nitrogen fertilizer is 27.76%, the cold water solubility is 20%, and the hot water solubility is 75%.

Embodiment 3

[0044] Biodegradable organic polymer nitrogen fertilizer, the preparation method of which is:

[0045] Add 1.00mol methyl carbamate, 0.10mol urea and 0.06mol catalyst potassium carbonate to the reaction vessel, react at 160°C for 6h, then add 0.02mol crosslinking agent triisocyanate, stir, when the reaction solution becomes viscous, Granulate and dry to obtain biodegradable organic high molecular nitrogen fertilizer.

[0046] The nitrogen content of the obtained biodegradable organic polymer nitrogen fertilizer is 28.25%, the solubility in cold water is 30%, and the solubility in hot water is 81%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com