Alkaline battery negative electrode synthetic gel agent

An alkaline battery and synthetic gel technology, which is applied in the field of alkaline battery negative electrode synthetic gel and synthetic gel, can solve the problems of alkaline electrolyte leaching, leakage, and damage to the performance of alkaline batteries, and achieve improved The effect of stability and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

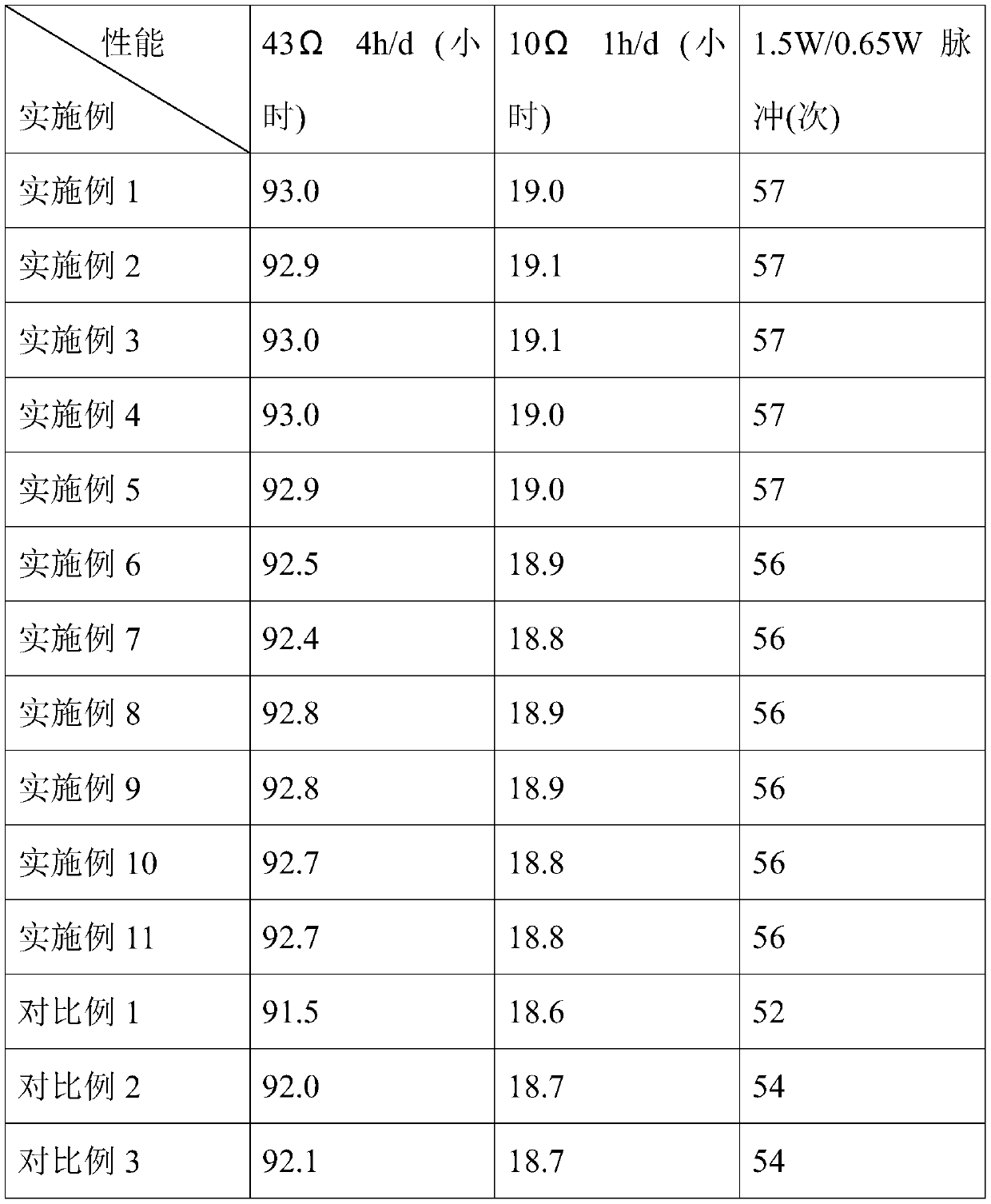

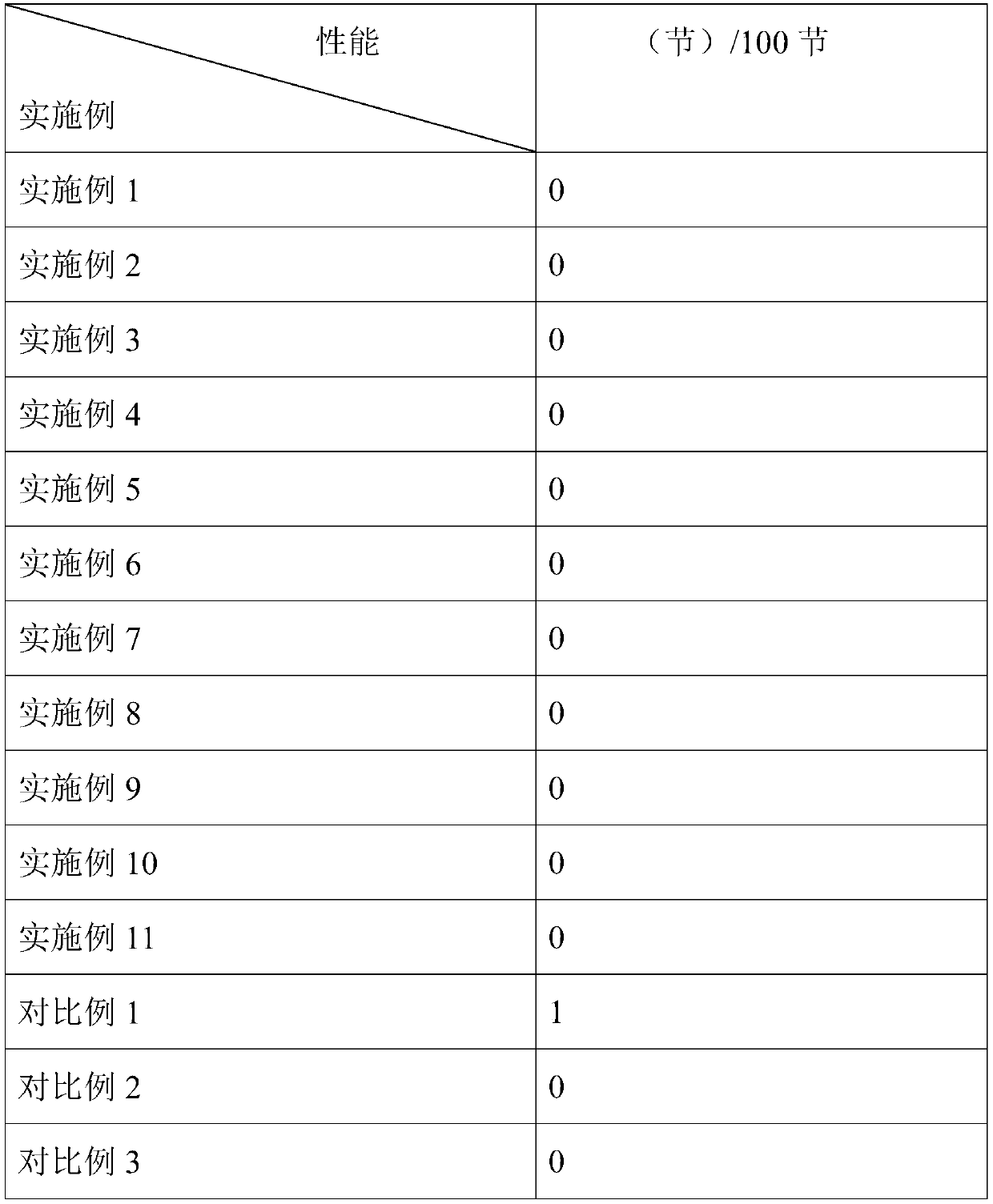

Examples

Embodiment 1

[0022] Add polyacrylate: 80%, propyltrimethoxysilane 12%, N,N-methylene acrylamide 0.2%, potassium persulfate 1.0% to the reaction kettle, and react to synthesize gel polymerization under the condition of pH 6.0 The reaction synthesis time is 4.5h, and the gel polymer is dried and ground into powder to obtain the negative electrode synthesis gel of alkaline batteries; zinc powder, common gel, corrosion inhibitor, and negative electrode synthesis gel of alkaline batteries are weighed. After the gel is mixed and dry-mixed, the electrolyte is added for mixing and wet-mixed, and after stirring and vacuuming, the zinc paste is made into the alkaline battery through a special syringe for zinc paste. The ordinary gel The agent is polyacrylate sodium salt.

Embodiment 2

[0024] Add polyacrylate: 81%, propyltrimethoxysilane 13%, N,N-methylene acrylamide 0.4%, potassium persulfate 2% to the reaction kettle, react to synthesize gel polymerization under the condition of pH 6.2 material, the reaction synthesis time is 4.8h, and the gel polymer is dried and ground into powder to obtain the negative electrode synthetic gel of alkaline battery; take zinc powder, common gel, corrosion inhibitor, negative electrode synthetic gel of alkaline battery After the gel is mixed and dry-mixed, the electrolyte is added for mixing and wet-mixed, and after stirring and vacuuming, the zinc paste is made into the alkaline battery through a special syringe for zinc paste. The ordinary gel The agent is polyacrylate sodium salt.

Embodiment 3

[0026] Add polyacrylate: 83%, propyltrimethoxysilane 14%, N,N-methylene acrylamide 0.5%, potassium persulfate 2.5% to the reaction kettle, and react to synthesize gel polymerization under the condition of pH 6.5 material, the reaction synthesis time is 5h, and the gel polymer is dried and ground into powder to obtain the negative electrode synthetic gel of alkaline battery; take zinc powder, common gel, corrosion inhibitor, alkaline battery negative electrode synthetic gel After the glue is mixed and dry-mixed, the electrolyte is added for mixing and wet-mixed, and after stirring and vacuuming, it is made into zinc paste, and the zinc paste is injected into the alkaline battery through a special syringe for zinc paste. The ordinary gel Sodium polyacrylate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com