A kind of purification method of 5-methylpyrazine-2-carboxylic acid crude product

A technology of methylpyrazine and purification method, applied in chemical instruments and methods, separation methods, organic chemistry and other directions, can solve the problems of high production cost, large amount of mother liquor, and reduced purity, and achieves mass production and uniform material. , the effect of uncomplicated steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Adjust the pH of the 5-methylpyrazine-2-carboxylic acid solution to 2.0, and the 5-methylpyrazine-2-carboxylic acid solid is precipitated, centrifuged to obtain 5-methylpyrazine-2-carboxylic acid Crude;

[0032] (2) Spread the crude 5-methylpyrazine-2-carboxylic acid in the trough of the purification device, and stir at a stirring speed of 10r / min;

[0033] (3) Raise the temperature of the trough to 60°C to further remove moisture until the moisture content drops to 0.5%;

[0034] (4) Raise the temperature of the trough to 80°C, and start the vacuum pump and cooling system at the same time to vacuumize, and the vacuum degree is controlled at 500Pa;

[0035] (5) Nitrogen gas is introduced into the trough, and the vacuum degree is controlled at 2000Pa;

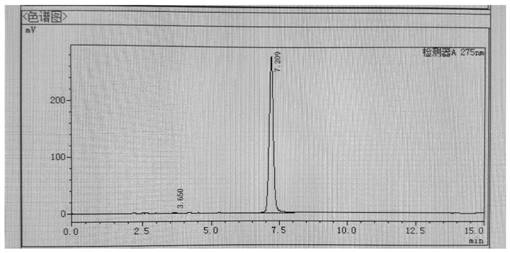

[0036] (6) The high-purity 5-methylpyrazine-2-carboxylic acid gas will be pumped into the crystallization kettle along with the nitrogen and vacuum system and condensed on the wall of the kettle, and the temperature...

Embodiment 2

[0044] (1) Adjust the pH of the 5-methylpyrazine-2-carboxylic acid solution to 1.8, the 5-methylpyrazine-2-carboxylic acid solid precipitates, and centrifuges to obtain 5-methylpyrazine-2-carboxylic acid Crude;

[0045] (2) Spread the crude product of 5-methylpyrazine-2-carboxylic acid in the trough of the purification device (the same as that used in Example 1) and stir at a stirring speed of 10r / min;

[0046] (3) Raise the temperature of the trough to 60°C to further remove moisture until the moisture content drops to 0.2%;

[0047] (4) Raise the temperature of the trough to 100°C, and start the vacuum pump and cooling system at the same time to vacuumize, and the vacuum degree is controlled at 650Pa;

[0048] (5) Nitrogen gas is introduced into the trough, and the vacuum degree is controlled at 1500Pa;

[0049] (6) The high-purity 5-methylpyrazine-2-carboxylic acid gas will be pumped into the crystallization kettle along with the nitrogen and vacuum system and condensed on ...

Embodiment 3

[0052] (1) Adjust the pH of the 5-methylpyrazine-2-carboxylic acid solution to 1.8, the 5-methylpyrazine-2-carboxylic acid solid precipitates, and centrifuges to obtain 5-methylpyrazine-2-carboxylic acid Crude;

[0053] (2) Spread the crude product of 5-methylpyrazine-2-carboxylic acid in the trough of a purification device (the same as that used in Example 1) and stir at a stirring speed of 50 r / min;

[0054] (3) Raise the temperature of the trough to 60°C to further remove moisture until the moisture content drops to 0.1%;

[0055] (4) Raise the temperature of the trough to 100°C, and start the vacuum pump and cooling system at the same time to vacuumize, and the vacuum degree is controlled at 500Pa;

[0056] (5) Nitrogen gas is introduced into the trough, and the vacuum degree is controlled at 5000Pa;

[0057] (6) The high-purity 5-methylpyrazine-2-carboxylic acid gas will be pumped into the crystallization kettle along with the nitrogen and vacuum system and condensed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com