Belt-load testing device used by a clutch electronic control pneumatic separating mechanism

A technology of pneumatic separation and testing device, which is used in the testing of machine/structural components, measuring devices, clutches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

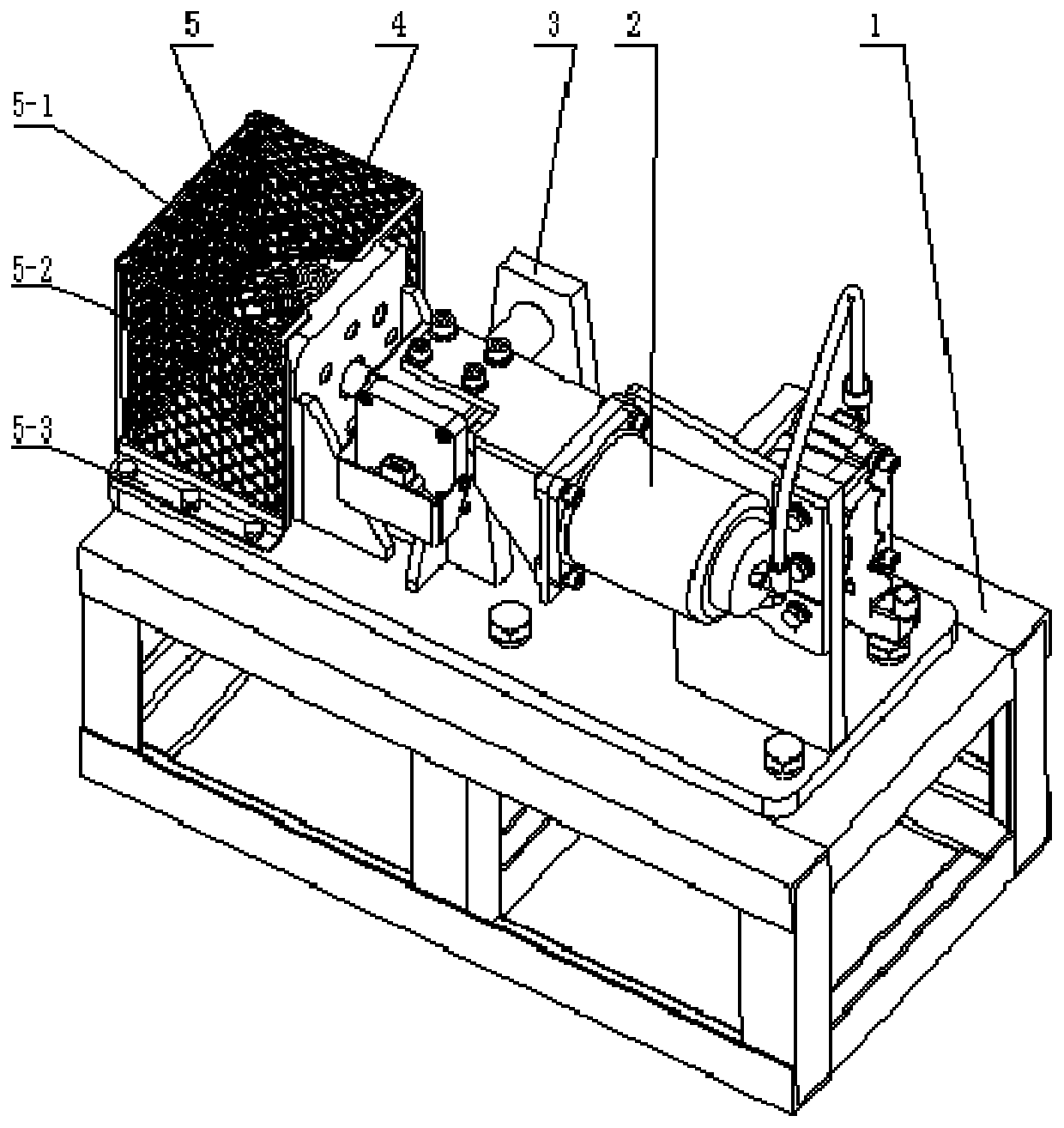

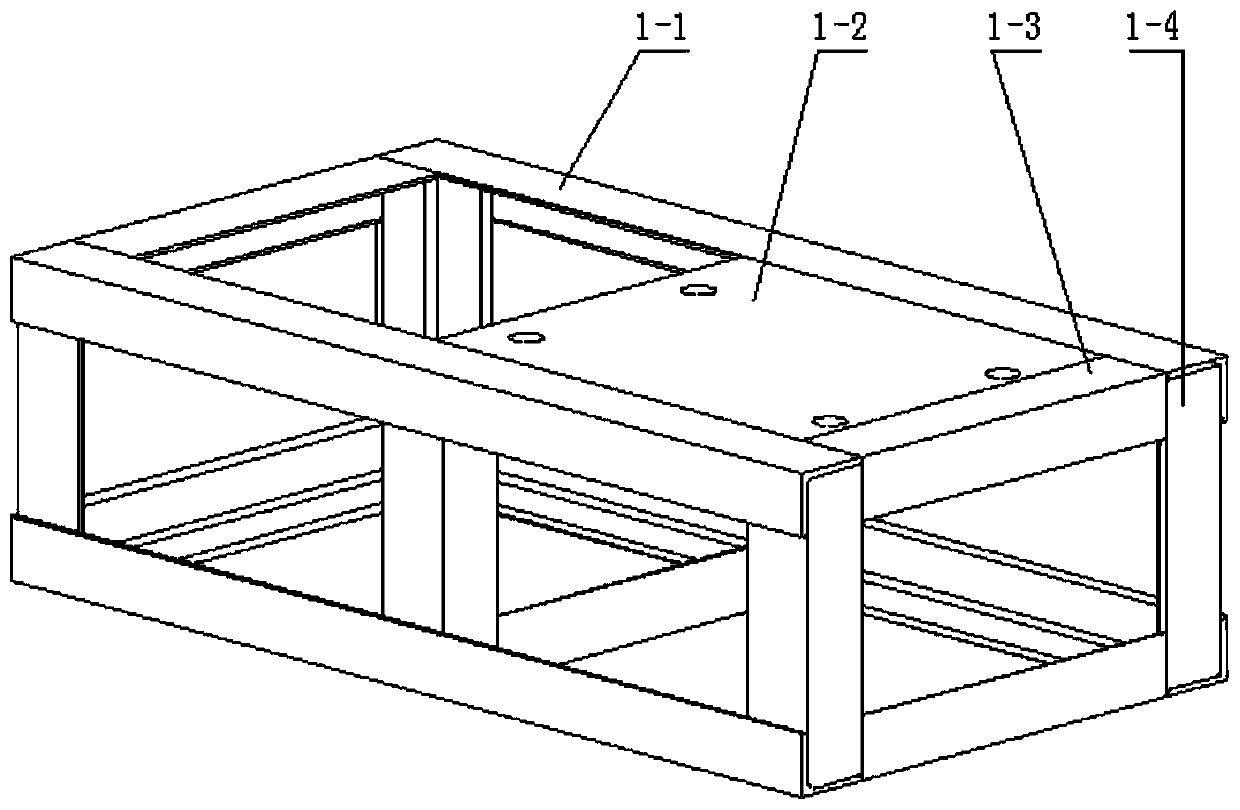

[0053] Such as figure 1 As shown, the on-load test device used by an electronically controlled pneumatic separation mechanism proposed by the present invention includes a base 1, an electronically controlled pneumatic separation mechanism 2, a support frame 3, and a disc mechanism 4;

[0054] The electro-pneumatic separation mechanism 2 includes a solenoid valve 2-1, an air pipe 2-2, a booster cylinder 2-3, and a combination bracket 2-4. The solenoid valve 2-1 is located on the side of the booster cylinder 2-3, and the side of the booster cylinder 2-3 The center line is consistent with the center line of the combined bracket 2-4;

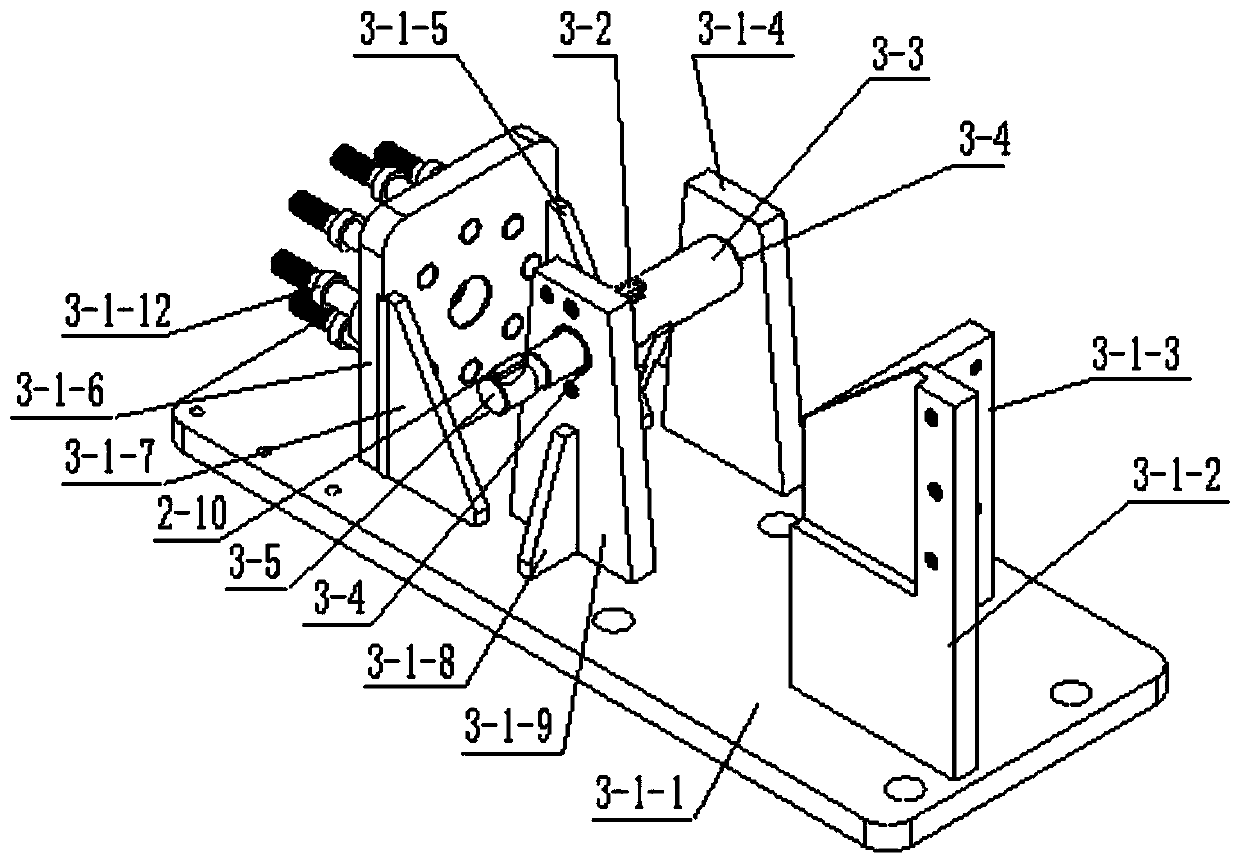

[0055] The support frame is located on the base, and an L-shaped support, a rotating shaft support frame, and a disc mechanism fixing plate 3-1-6 are sequentially arranged from one side of the base, and the axis of the rotating shaft support frame is perpendicular to the center line of the booster cylinder 2-3. The centerline of the fixed disk 3-1-...

Embodiment 2

[0067] Such as figure 1 As shown, the present invention proposes a load test device for an electropneumatic separation mechanism, which includes a base 1 , an electropneumatic separation mechanism 2 , a support frame 3 , a disc mechanism 4 , and a shield assembly 5 . The support frame 3 of the load testing device is seated on the base 1, the longitudinal long side of the support frame 3 is parallel to the longitudinal long side of the base 1, and the center line of the booster cylinder of the electro-pneumatic separation mechanism 2 is vertically longer than the support frame 3. The sides are parallel, perpendicular to the axis of the rotating shaft of the support frame 3, extending to the right above the front of the rotating shaft, and the center line of symmetry of the disc mechanism 4 is perpendicular to the axis of the rotating shaft on the support frame 3, and is located in the left front; the electric control pneumatic separation The swing arm of the mechanism 2 is inse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com