High-hardness flexible-packaging lithium ion battery pole piece and roll core manufacturing method

A lithium-ion battery and flexible packaging technology, applied in non-aqueous electrolyte battery electrodes, secondary batteries, battery pack components, etc., can solve the problem of shortened standby time and service life, large-scale lithium deposition in batteries, and uneven cell structure and other problems to achieve the effect of improving user experience, improving energy density, and improving cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

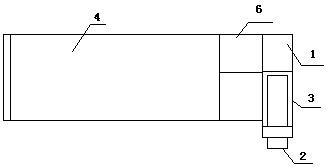

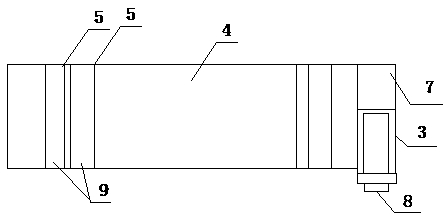

[0021] Such as Figure 1-2 As shown, a high-hardness soft-packaged lithium-ion battery pole piece includes a positive pole piece and a negative pole piece. The positive electrode active material is added with conductive agent, binder and other auxiliary materials. In order to effectively use the space of the finished battery and increase the safety of the finished battery, the positive electrode sheet is provided with an uncoated blank area, and the blank area can be used for tab welding and other operations. , generally the positive plate has 2-4 blank areas;

[0022] The positive tab of the pole piece is an aluminum tab or a protruding area is provided on the current collector as the tab. The surface of the welding tab and the surface of the opposite side are affixed with a safety tape. The design requirements for the width of the safety tape are: It can overlap with the width direction of the coating line tape to the greatest extent, and does not overlap with the negative ...

Embodiment 2

[0028] Such as Figure 1-2 As shown, a high-hardness soft-pack lithium-ion battery pole piece includes a positive pole piece and a negative pole piece, and the positive pole piece is provided with a coated area and an uncoated blank area, and the coated area and the uncoated blank area A protective tape is pasted at the junction, and a safety tape is pasted on the surface of the welding tab of the positive electrode sheet and the surface of the opposite side;

[0029] The negative electrode sheet is provided with a coated area and an uncoated blank area, and a safety tape is pasted on the surface of the welding tab of the negative electrode sheet and the surface of the opposite side; the lower blank area of the negative electrode sheet is pasted with a balance adhesive tape.

[0030] Preferably, the positive tab of the pole piece is an aluminum tab or a protruding area is provided on the current collector as a tab; the negative tab of the pole piece is an aluminum tab or a ...

Embodiment 3

[0038] A method for preparing a high-hardness soft-packaged lithium-ion battery core. The positive and negative pole pieces and the diaphragm are wound into a core by manual winding, semi-automatic or automatic winding. The positive and negative pole pieces are separated by a diaphragm. The end of the core is designed to be located in the middle area of the tab (not overlapping with the positive and negative tabs), and terminated with a termination tape. After the core is wound, it goes through the process of shelling, assembling, baking to remove water, liquid injection, packaging, etc., and then undergoes high-temperature pressurized formation. The uncharged semi-finished battery is given a certain pressure by baking fixture or high-temperature pressurized formation cabinet. The temperature realizes charging activation and product finalization.

[0039] Preferably, the diaphragm is a ceramic plus PVDF adhesive coating diaphragm, which can aggregate the pole pieces and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com