Pulverizing device used for producing ceramics

A crushing device and ceramic technology, applied in heating devices, lighting and heating equipment, drying, etc., can solve the problems of low crushing efficiency, no impurity removal, troublesome feeding and discharging, etc., to improve work efficiency and crushing efficiency High, quality-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

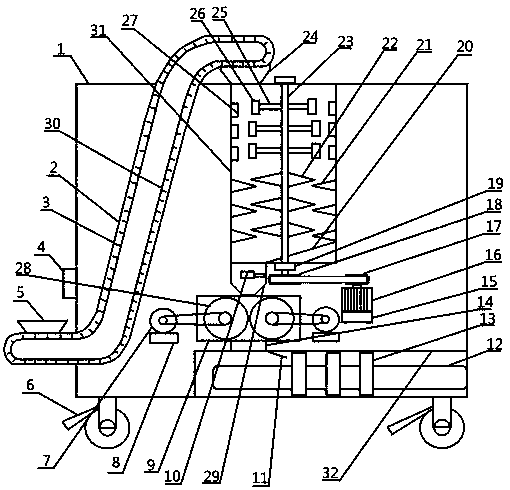

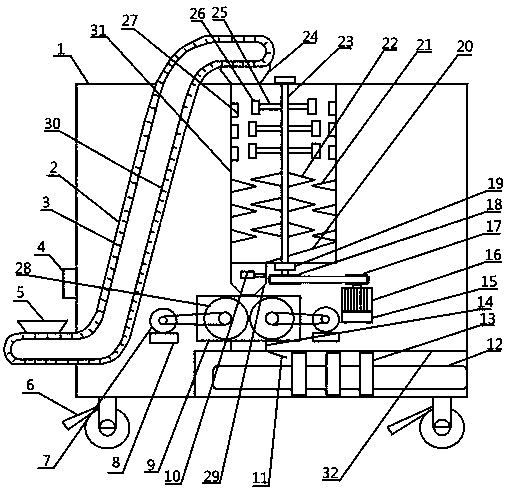

[0020] A crushing device for producing ceramics, comprising a frame 1, a conveyor protective shell 2, a feed port 5, a universal self-locking wheel 6, a motor, a pressure roller chamber 9, an electromagnet 10, a belt conveyor, and a microwave generator 13 , discharge pipe 14, pulverizing teeth, rotating shaft, pulverizing hammer 26, pulverizing cylinder 31 and pressure roller 28; Described motor comprises pressure roller motor 7 and pulverizing motor 16; Described belt conveyor comprises discharging belt conveyor 12 And feed belt conveyor 30; Described rotating shaft comprises first rotating shaft 23 and second rotating shaft; Described pulverizing tooth comprises first pulverizing tooth 22 and second pulverizing tooth 21;

[0021] The conveyor protective shell 2 is set on the frame 1; the feeding belt conveyor 30 is set in the conveyor protective shell 2; the feeding port 5 is set on the conveyor protective shell 2; The crushing cylinder 31 is arranged on the frame 1, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com