A kind of strong adhesion marking ink, its preparation method and strong adhesion marking pen

A technology for adhesion and marking pens, which can be applied to other ink pens, inks, printing, etc., and can solve problems such as poor adhesion fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

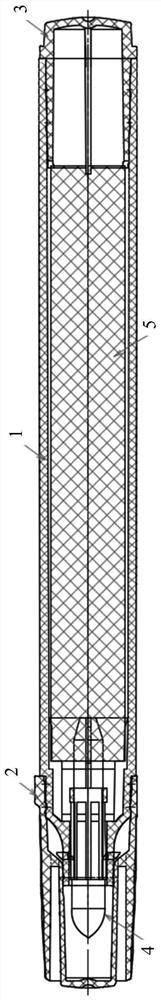

Image

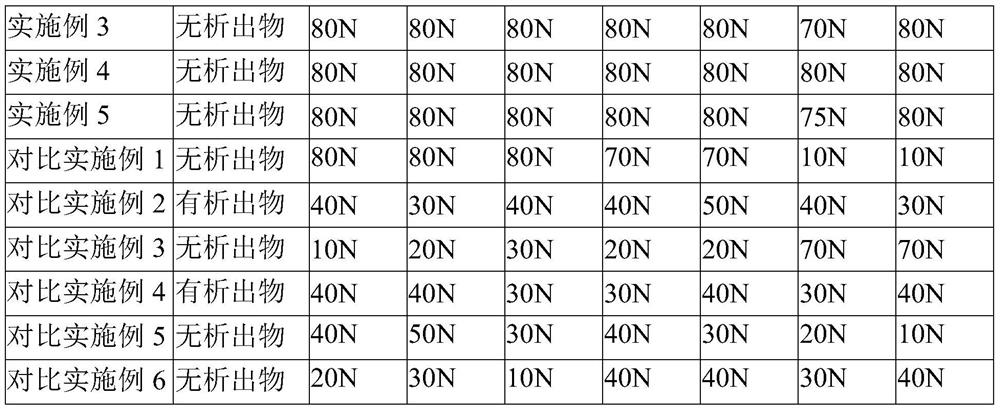

Examples

Embodiment 1

[0086] Add 35 parts by weight of ethanol, 30 parts by weight of ethylene glycol-methyl ether and 10 parts by weight of direct black ASF600 dyestuff into a reaction kettle with stirring equipment (stirring speed is 400rpm), and obtain a uniform solution after stirring for 2 hours. Add 12 parts by weight of alcohol-soluble dimer acid polyamide resin and 10 parts by weight of alkyd resin, and finally add 0.5 parts by weight of n-propanol and 0.5 parts by weight of adipate and heat to 40-60 ° C, keep stirring for 4 A homogeneous solution was obtained after 1 hour, and a strong adhesive marking ink was obtained after filtration.

Embodiment 2

[0088] Add 35 parts by weight of ethanol, 30 parts by weight of ethylene glycol-methyl ether and 10 parts by weight of solvent blue 58 dye into a reactor equipped with a stirring device (stirring speed: 400 rpm), and stir for 2 hours to obtain a uniform solution. Add 13 parts by weight of alcohol-soluble dimer acid polyamide resin and 9 parts by weight of alkyd resin under stirring, and finally add 0.5 parts by weight of n-propanol and 0.5 parts by weight of adipate and heat to 40-60 ° C, After heat preservation and stirring for 4 hours, a uniform solution was obtained, and after filtration, a marking ink with strong adhesion was obtained.

Embodiment 3

[0090] Add 35 parts by weight of ethanol, 30 parts by weight of ethylene glycol-methyl ether and 10 parts by weight of Direct Red 4GE dye into a reactor equipped with a stirring device (stirring speed: 400 rpm), and stir for 2 hours to obtain a uniform solution. Add 14 parts by weight of alcohol-soluble dimer acid polyamide resin and 8 parts by weight of alkyd resin under stirring, and finally add 0.5 parts by weight of n-propanol and 0.5 parts by weight of adipate and heat to 40-60 ° C, After heat preservation and stirring for 4 hours, a uniform solution was obtained, and after filtration, a marking ink with strong adhesion was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com