Saccharification machine for microbial fermentation

A technology for microbial fermentation and fermenter, which is applied in bioreactor/fermenter combination, biochemical cleaning device, bioreactor/fermenter for specific purposes, etc. The problem of long microbial fermentation time, etc., can achieve the effect of increasing the fermentation time, improving the saccharification effect, and increasing the amount of dissolved oxygen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

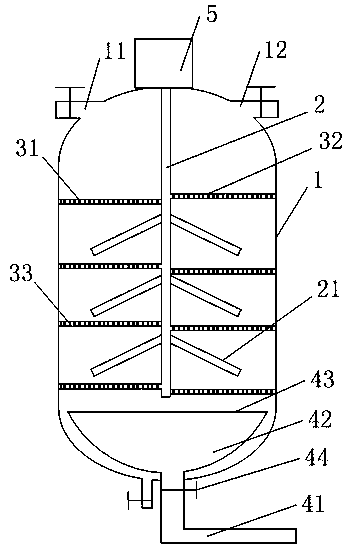

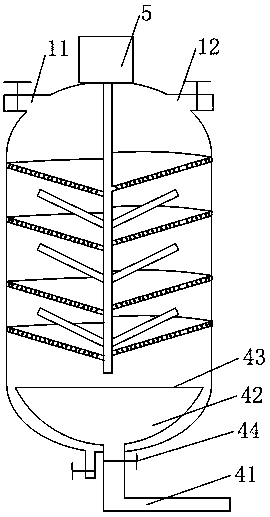

[0020] Such as figure 1 , 3 The shown saccharification machine for microbial fermentation includes a fermenter 1, a stirring bar 2 coaxially arranged with the fermenter 1, and an air outlet 11 arranged on the fermenter 1, which is the same as the existing structure, and the fermenter is also provided with a The feed port 12, the feed port, and the bottom of the fermenter 1 are provided with an air delivery device. The fermenter 1 is provided with a multi-layer partition, and the partition includes a first fan-shaped plate 31 and a second fan-shaped plate 32. The larger arc edge of the first fan-shaped plate 31 is fixed on the inner wall of the fermenter 1 and the smaller The arc edge is attached to the stirring rod 2, the smaller arc edge of the second fan-shaped plate 32 is fixed on the stirring rod 2 and the larger arc edge is attached to the inner wall of the fermentation tank 1, and the rotation of the stirring rod can drive the second fan-shaped plate 32 to rotate , the...

Embodiment 2

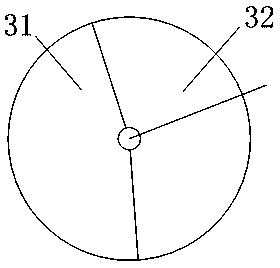

[0022] This embodiment optimizes the first fan-shaped plate 31 and the second fan-shaped plate 32 on the basis of the structure of the above-mentioned embodiment, that is, as figure 2 As shown, both the first fan-shaped plate 31 and the second fan-shaped plate 32 are arranged perpendicular to the stirring rod, but this structure is not convenient for cleaning the fermenter 1 .

[0023] can also be used as figure 2 In the structure shown, the height of the larger arc side of the first fan-shaped plate 31 and the second fan-shaped plate 32 is higher than the height of the smaller arc side, that is, there is a certain angle between the first fan-shaped plate 31 and the horizontal plane. Preferably, the included angle between the first fan-shaped plate 31 and the stirring rod 2 is greater than 40 degrees and less than 80 degrees. The angle between the first fan-shaped plate 31 and the stirring rod 2 is 60 degrees. Preferably, the length of the larger arc side of the first fan-...

Embodiment 3

[0025] This embodiment has been optimized on the basis of the structure of the above-mentioned embodiment, that is, the stirring blade 21 can also be fixed on the stirring rod 2, and the stirring blade 21 is placed between the adjacent two-layer partitions and the stirring blade 21 is connected to the first fan-shaped plate. 31 are not parallel.

[0026] The air supply device comprises an air supply pipe 41, a buffer chamber 42 communicated with the air supply pipe 41, and an air uniform plate 41 arranged on the top surface of the buffer chamber 42. The air supply pipe 41 is provided with a one-way valve 44, and the air uniform plate 43 is Provided with vent holes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com