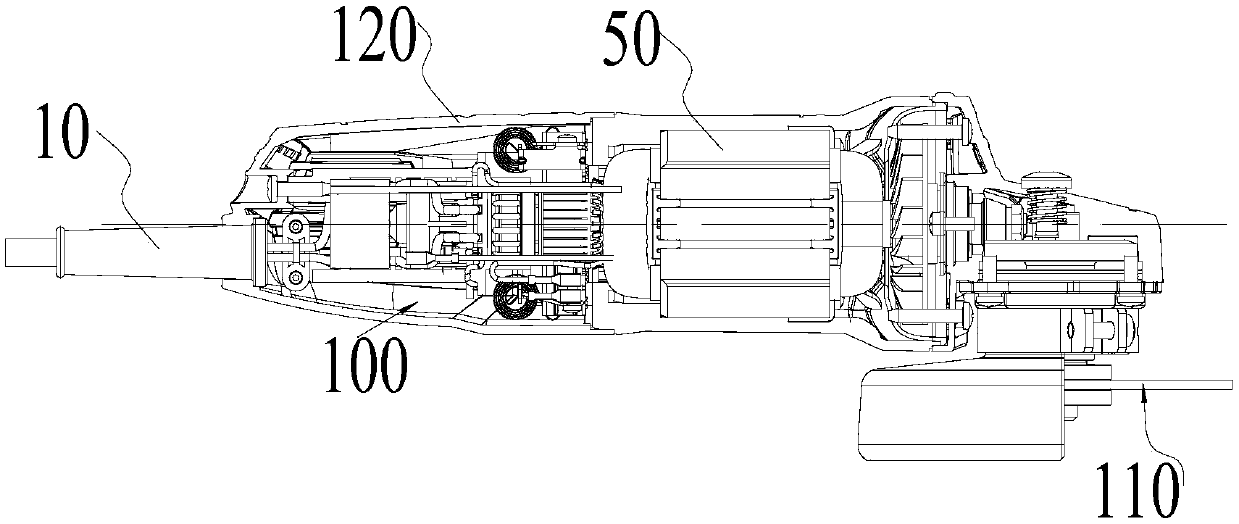

Angle grinder and electrical tool

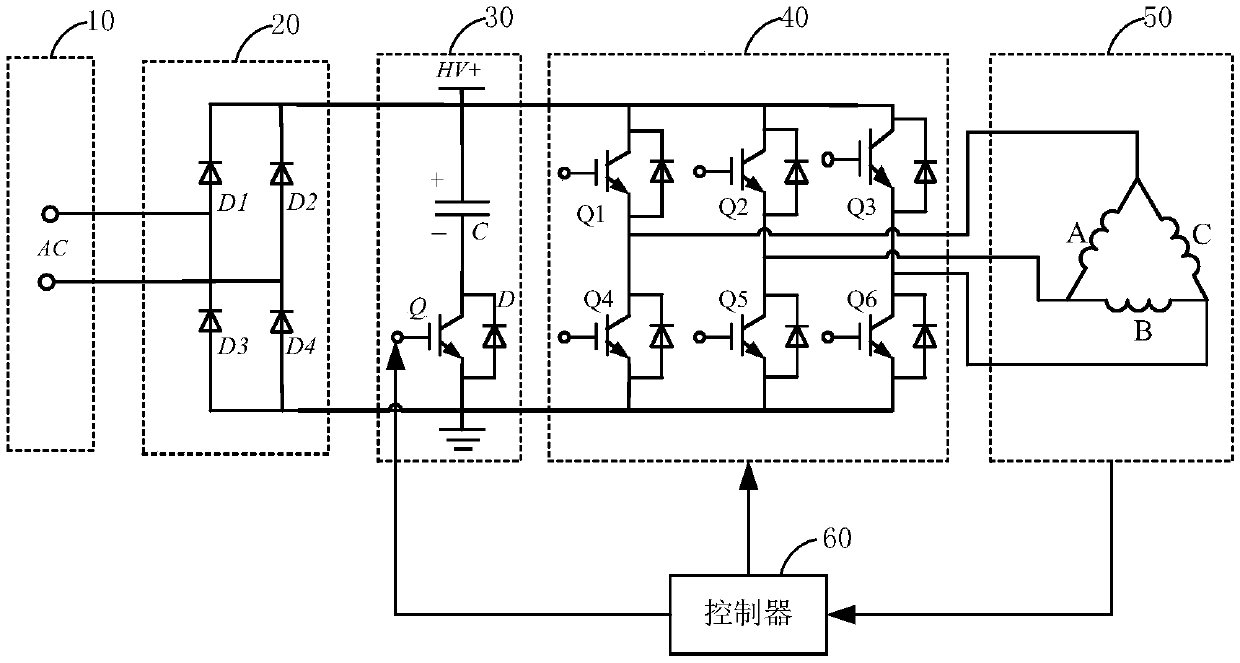

A technology of angle grinding and capacitance, applied in angle grinding. field, able to solve problems such as power shocks and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

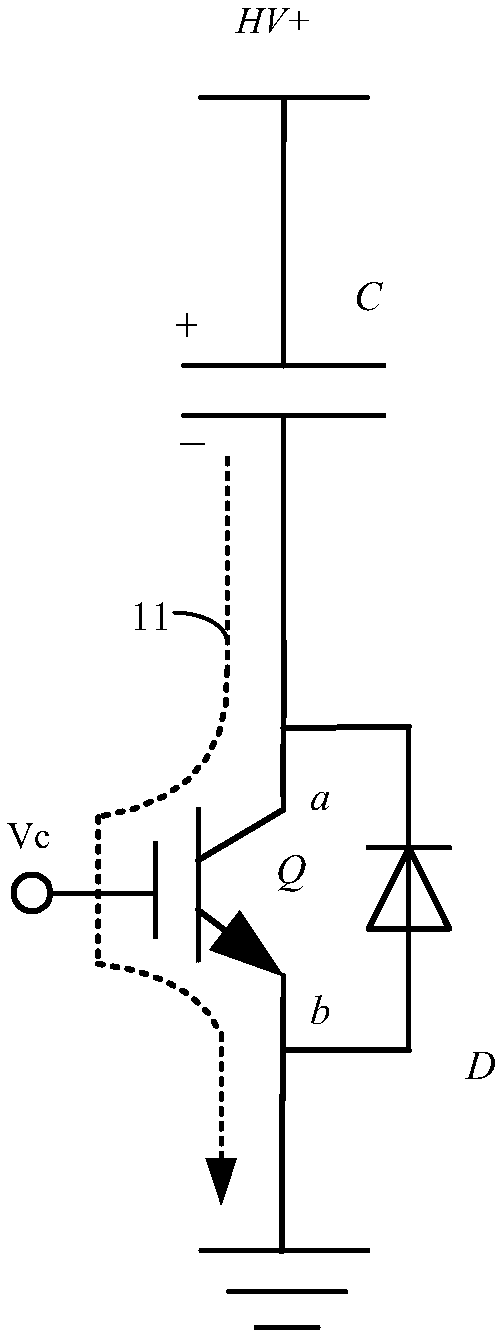

Embodiment approach

[0107] Those skilled in the art should understand that the second condition here is independent of the power-on state or the first rotational speed of the electric tool. That is, in one embodiment of the present invention, no matter whether the electric tool is powered on or not, or whether the electric tool has the first rotating speed, the power switch tube can be activated accordingly by judging whether the electric tool meets the second condition. Q turns off or turns off gradually. For example, when the second condition is that the rotation speed of the motor reaches the second rotation speed, whether the motor reaches the second rotation speed can be judged independently without considering whether the electric tool is powered on or whether the first rotation speed is met, and through the control unit, Outputting a PWM duty ratio signal to control switching elements such as the power switch tube Q to turn off or gradually turn off, so that the capacitor circuit is in a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com