A kind of hypromellose enteric-coated empty capsule with calcium salt, potassium salt and sodium salt gel

A technology of hypromellose and hollow capsules, which is applied in the fields of capsule transportation, medical preparations of non-active ingredients, and pharmaceutical formulas, which can solve the problems of large capsules and low production efficiency, achieve low water content, and increase production costs. Modulus, non-perishable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

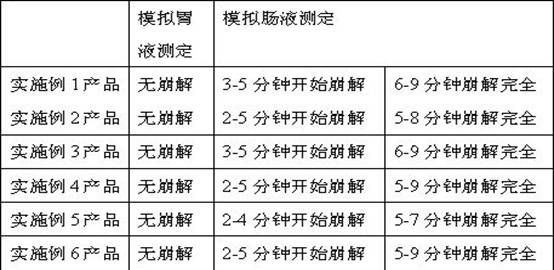

Examples

Embodiment 1

[0025] (1) Take 50kg of hypromellose, put it into 120L of purified water at a temperature of 87°C, stir and mix rapidly for 9 minutes, and then keep it for 60 minutes at a temperature of 80°C to obtain a hypromellose solution.

[0026] (2) Stir and swell 430 g of gellan gum in 120 L of purified water at a temperature of 40° C., then heat to 85° C. and keep it for 55 minutes to obtain gellan gum swelling liquid.

[0027] (3) Add the gellan gum swelling solution to the hypromellose solution at a temperature 4°C higher than that of the hypromellose solution, and add the hypromellose solution and the gellan gum swelling solution at the same temperature Pour into the mixing kettle at the same time and start stirring when pouring in. After pouring, keep stirring and mixing for 9 minutes, and then cool to 75°C to obtain hypromellose gel solution.

[0028] (4) Add 210 g of calcium chloride to the hypromellose gel solution, stir at a speed of 900 rpm for 2 minutes, then vacuumize and f...

Embodiment 2

[0038] (1) Take 50kg of hypromellose, put it into 125L of purified water at a temperature of 92°C, stir and mix quickly for 13 minutes, and then keep it at a temperature of 85°C for 75 minutes to obtain a hypromellose solution.

[0039] (2) Stir and swell 466 g of gellan gum in 125 L of purified water at a temperature of 42.5° C., then heat to 90° C. and keep it for 60 minutes to obtain gellan gum swelling liquid.

[0040] (3) Add the gellan gum swelling solution to the hypromellose solution at a temperature 5°C higher than that of the hypromellose solution, and add the hypromellose solution and the gellan gum swelling solution at the same temperature Pour it into the mixing tank at the same time and start stirring when pouring in. After pouring, keep stirring and mixing for 13 minutes, and then cool to 80°C to obtain hypromellose gel solution.

[0041] (4) Add 235 g of calcium chloride to the hypromellose gel solution, stir at a speed of 1000 rpm for 2.5 min, then vacuumize and...

Embodiment 3

[0050] (1) Take 50kg of hypromellose, put it into 130L of purified water at a temperature of 98°C, stir and mix rapidly for 17 minutes, and then keep it standing for 90 minutes at a temperature of 92°C to obtain a hypromellose solution.

[0051] (2) Stir and swell 490 g of gellan gum in 130 L of purified water at a temperature of 45° C., then heat to 95° C. and keep it for 65 minutes to obtain gellan gum swelling liquid.

[0052] (3) Add the gellan gum swelling solution to the hypromellose solution at a temperature 6°C higher than that of the hypromellose solution, and add the hypromellose solution and the gellan gum swelling solution at the same temperature Pour into the mixing tank at the same time and start stirring when pouring in. After pouring, keep stirring and mixing for 17 minutes, and then cool to 85°C to obtain hypromellose gel solution.

[0053] (4) Add 250 g of calcium chloride to the hypromellose gel solution, stir at a speed of 1100 rpm for 3 minutes, then vacuu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com