Multifunctional interior wall coating and preparation method and application thereof

An interior paint, multifunctional technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0140] In a second aspect, in at least one embodiment, a method for preparing a multifunctional interior wall paint is provided, comprising the following steps: adding material B-composite nano-zinc oxide prefabricated slurry to the prepared material A-front-end dispersion slurry and Material C was mixed to obtain a multifunctional interior wall paint.

[0141] The preparation method has simple operation steps, is easy to implement, has low cost, high efficiency, and is easy to realize large-scale production. Simultaneously, each component of the present invention is used as a raw material, and the proportion of each component raw material is appropriate, and the prepared coating has the characteristics of high performance and multifunctionality of anti-mildew and anti-bacterial, anti-yellowing, high-efficiency formaldehyde removal.

[0142] Preferably, the preparation of the material B-composite nano-zinc oxide prefabricated slurry includes: first mixing the water in the form...

Embodiment 1-3

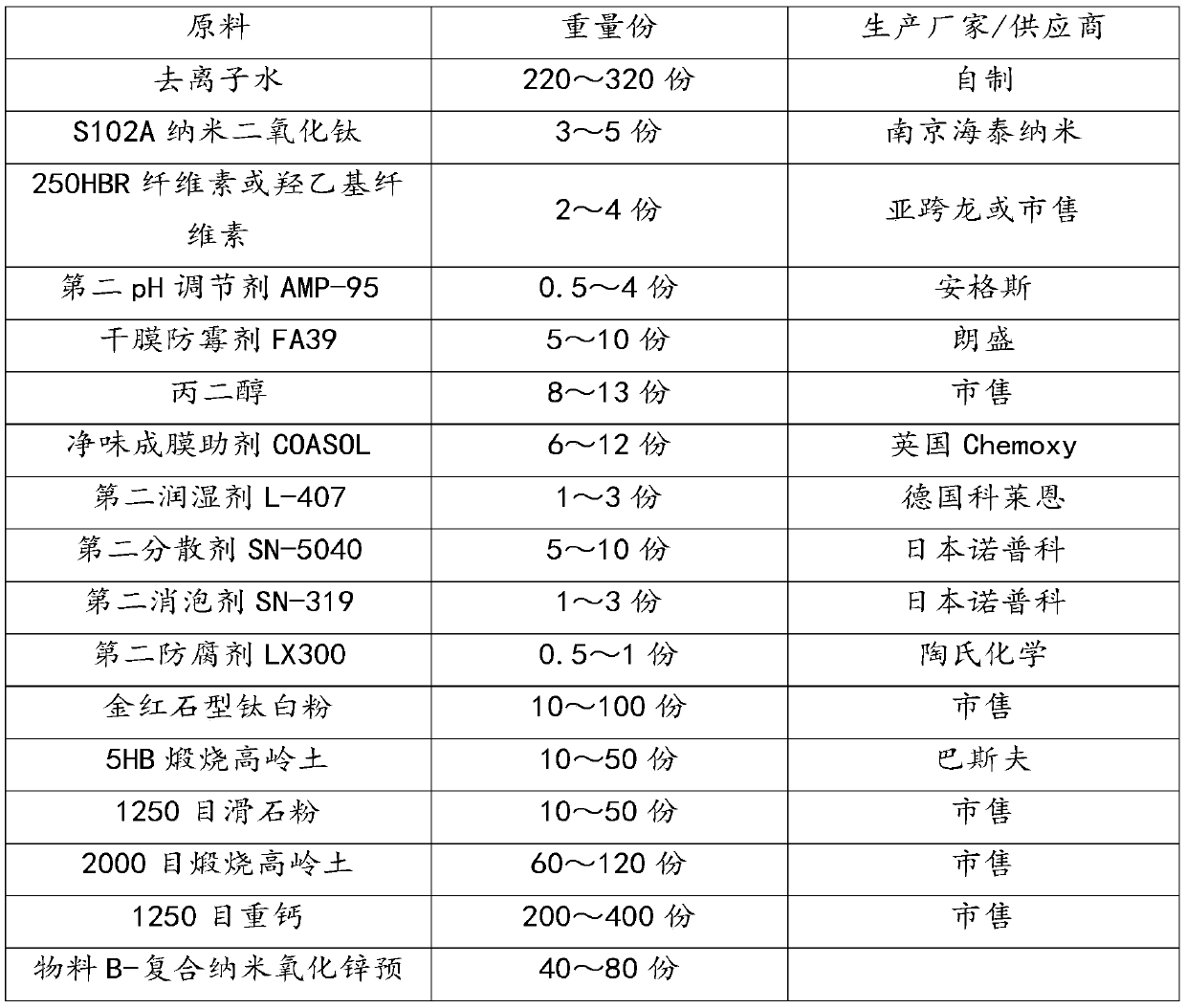

[0151] A kind of multifunctional interior wall paint, its formula and manufacturer / supplier are as shown in Table 3. Among them, the formula and the manufacturer / supplier of the material B-composite nano-zinc oxide prefabricated slurry are shown in Table 4.

[0152] Formulation and manufacturer / supplier of the multifunctional interior wall coating of table 3 embodiment 1-3

[0153]

[0154]

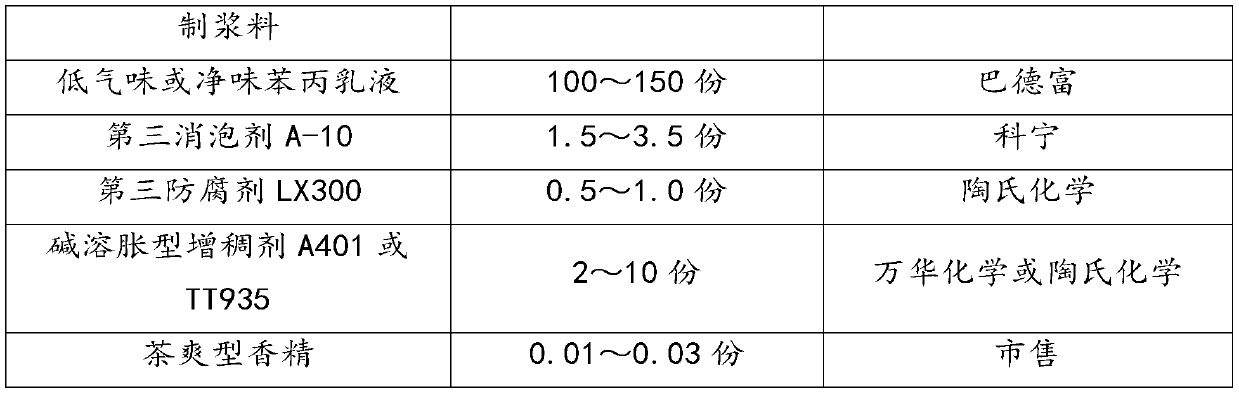

[0155] Formulation and manufacturer / supplier of material B in Table 4 embodiment 1-3

[0156]

[0157]

Embodiment 4

[0159] A kind of multifunctional interior wall paint, the difference with embodiment 1 is the formula of material B;

[0160] In this example, material B-composite nano-zinc oxide prefabricated slurry includes by weight percentage: 45% deionized water, 0.3% commercially available hydroxyethyl cellulose, 0.2% pH regulator AMP-95, and 0.2% preservative LX300 , defoamer SN-319 0.4%, dispersant SN-5040 3.0%, wetting agent L-407 0.5% and nano-composite zinc oxide powder 50.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com