A kind of universal qpq nitriding agent concentration adjustment method

A technology of concentration adjustment and nitriding agent, which is applied in the direction of instruments, solid-state diffusion coatings, coatings, etc., can solve the problems of affecting production efficiency, long time consumption, and large impact on accuracy, and achieve the effect of saving labor costs and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

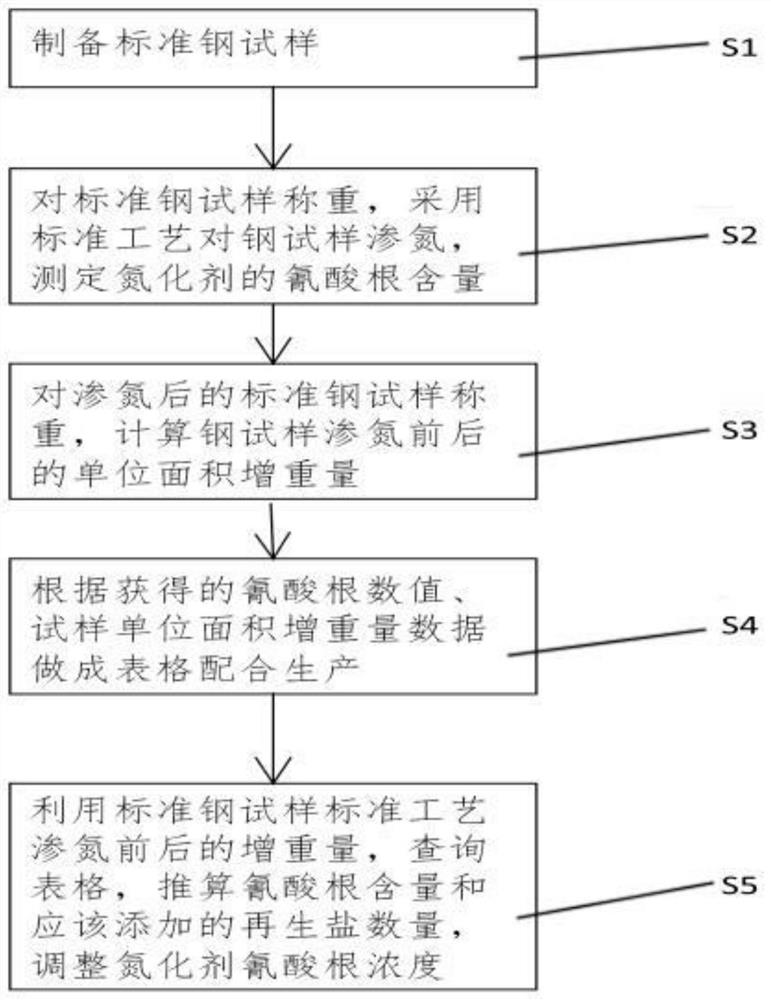

[0024] Such as figure 1 A kind of general type QPQ nitriding agent concentration adjustment method shown, described method comprises the following steps:

[0025] S1 preparation of standard steel samples;

[0026] S2 Weigh the standard steel sample, nitriding the steel sample by standard process, and measure the cyanate content of the nitriding agent;

[0027] S3 weighs the standard steel sample after nitriding, and calculates the weight gain per unit area of the steel sample before and after nitriding;

[0028] S4 Make a table according to the obtained cyanate value and the weight gain data per unit area of the sample to cooperate with the production;

[0029] S5 uses the weight gain before and after nitriding of the standard steel sample standard process to query the table to calculate the cyanate content data and the amount of regeneration salt that should be added to achieve the purpose of adjusting the nitriding agent bath.

[0030] This embodiment can easily, quic...

Embodiment 2

[0032] This embodiment discloses a general nitriding agent concentration adjustment method, specifically as follows:

[0033] 1) Prepare a batch of 45 steel samples, the surface roughness is Ra0.2, the surface texture state is quenched and tempered state, and the sample size is 30mm×20mm×5mm. (The 45 steel sample can be replaced by any nitriding sample, and the size can be changed according to the situation, but the same size should be guaranteed)

[0034] 2) For a specific nitriding agent, use the chemical analysis method to measure the cyanate content. At the same time, put three samples in the nitriding agent, and nitriding at 570°C for 2 hours. Weigh with a professional electronic balance, calculate the weight gain per unit area of each sample after nitriding, and take the average value.

[0035] 3) Repeat step 2 continuously to obtain the weight gain per unit area of the 45 steel sample corresponding to different cyanate content.

[0036] 4) Form the obtained cyanat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com