Preparation method of a flexible pressure sensor based on silver-plated polyester

A pressure sensor and sensor technology, which is applied in the direction of instruments, measuring force, liquid chemical plating, etc., can solve the problems of heavy weight, low sensitivity, and contact sensitivity of the sensor, and achieve the effect of high sensitivity, response time, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

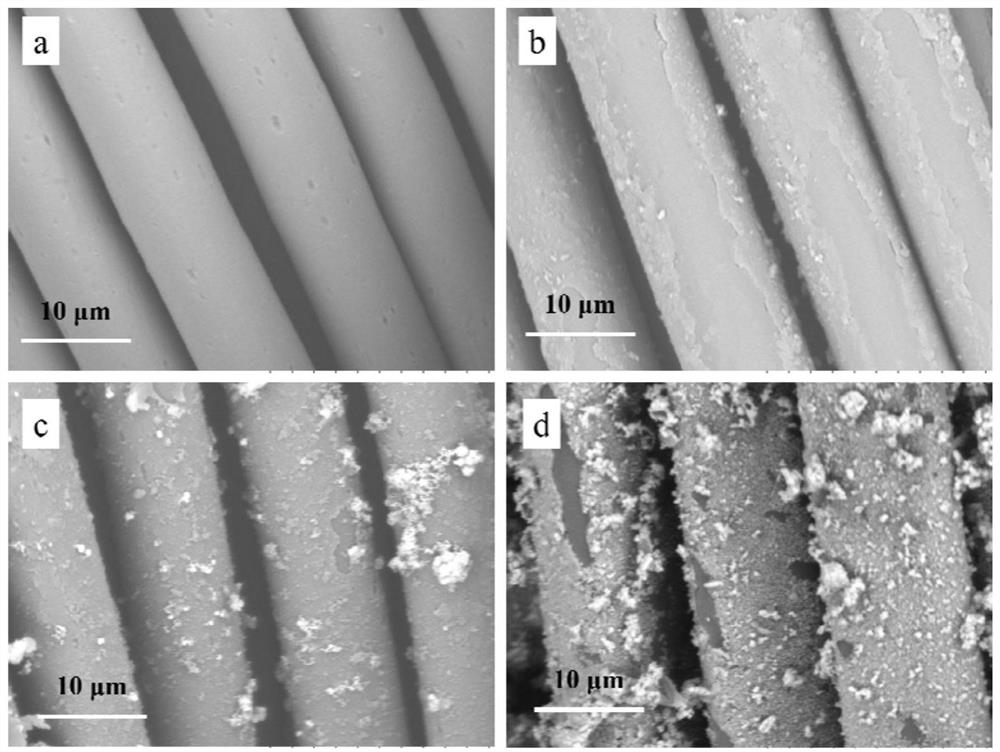

[0047]Fabric roughening treatment: Sodium hydroxide 30g / L, bath ratio 50:1, soak the fabric in the treatment solution, 20°C, treat for 50min. Subsequently, the fabric was washed twice with water, neutralized with acetic acid (0.5g / L), washed with water, and dried in the air to be tested.

Embodiment 2

[0049] (1) Fabric roughening treatment

[0050] Sodium hydroxide 30g / L, bath ratio 50:1, soak the fabric in the treatment solution, 20°C, treat for 50min. The fabric was then washed twice with water, neutralized with acetic acid (0.5 g / L), washed with water, and dried in the air.

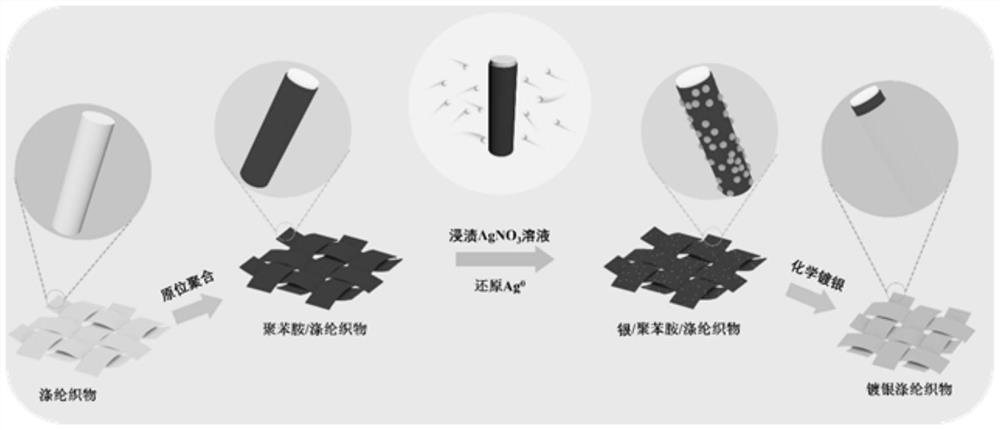

[0051] (2) In situ polymerization of aniline

[0052] Immerse the roughened fabric in 0.5 mol / L of nitric acid solution containing 0.25 mol / L of aniline monomer for 30 minutes to make it fully adsorb the aniline monomer, then add 0.3 mol / L of ammonium persulfate solution and stir evenly. Seal the reaction, polymerize for 2 hours, fully wash with water, wash with acetone, wash with distilled water, repeat several times, dry in the air, and wait for the test.

Embodiment 3

[0054] (1) Fabric roughening treatment

[0055] Sodium hydroxide 30g / L, bath ratio 50:1, soak the fabric in the treatment solution, 20°C, treat for 50min. The fabric was then washed twice with water, neutralized with acetic acid (0.5 g / L), washed with water, and dried in the air.

[0056] (2) In situ polymerization of aniline

[0057] Immerse the roughened fabric in 0.5 mol / L of nitric acid solution containing 0.25 mol / L of aniline monomer for 30 minutes to make it fully adsorb the aniline monomer, then add 0.3 mol / L of ammonium persulfate solution and stir evenly. Seal the reaction, polymerize for 2 hours, fully wash with water, wash with acetone, wash with distilled water, repeat several times, and dry in the air.

[0058] (3) activation

[0059] Take an appropriate amount of polymerized polyaniline composite fabric and seal and dip it in 2g / L silver nitrate solution for 5 hours, take it out, wash it with distilled water and ethanol, repeat several times, dry it, and wait...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com