Earth road shoulder forming paver

A technology for paver and soil road shoulder, applied in the field of data road shoulder forming construction machinery, can solve the problems of increasing construction procedures and labor, increasing labor costs, slow production efficiency, etc., and reducing construction procedures and labor intensity, versatility The effect of strengthening and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further explained below in conjunction with the accompanying drawings.

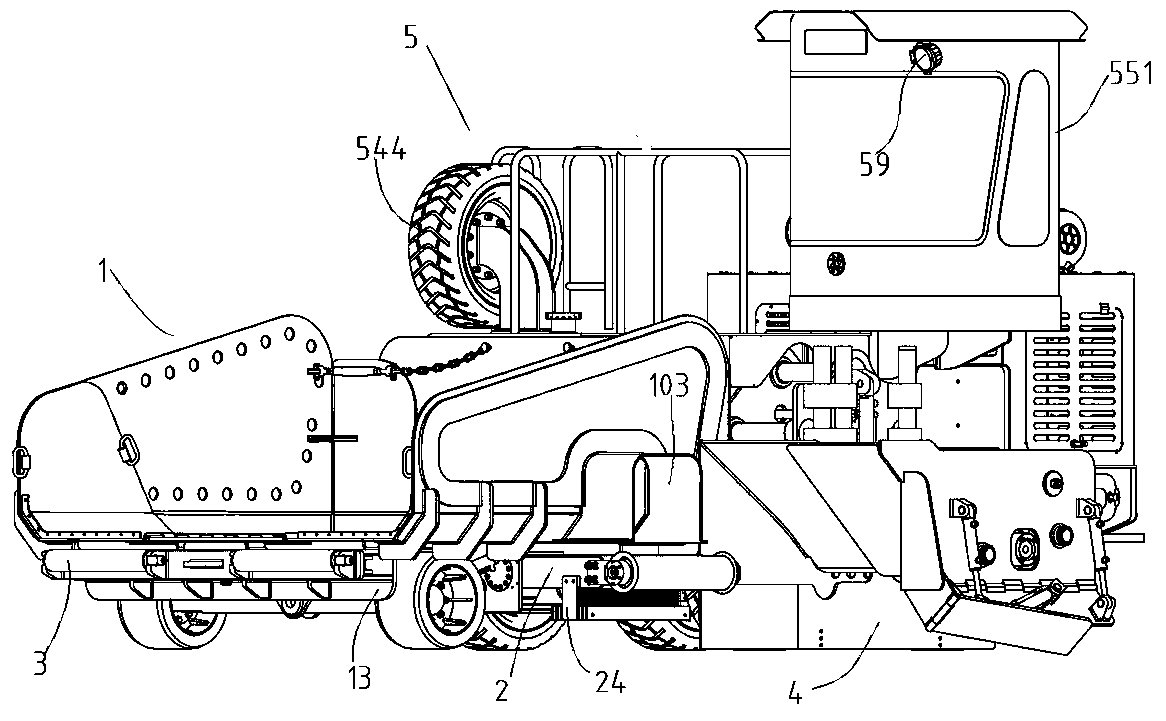

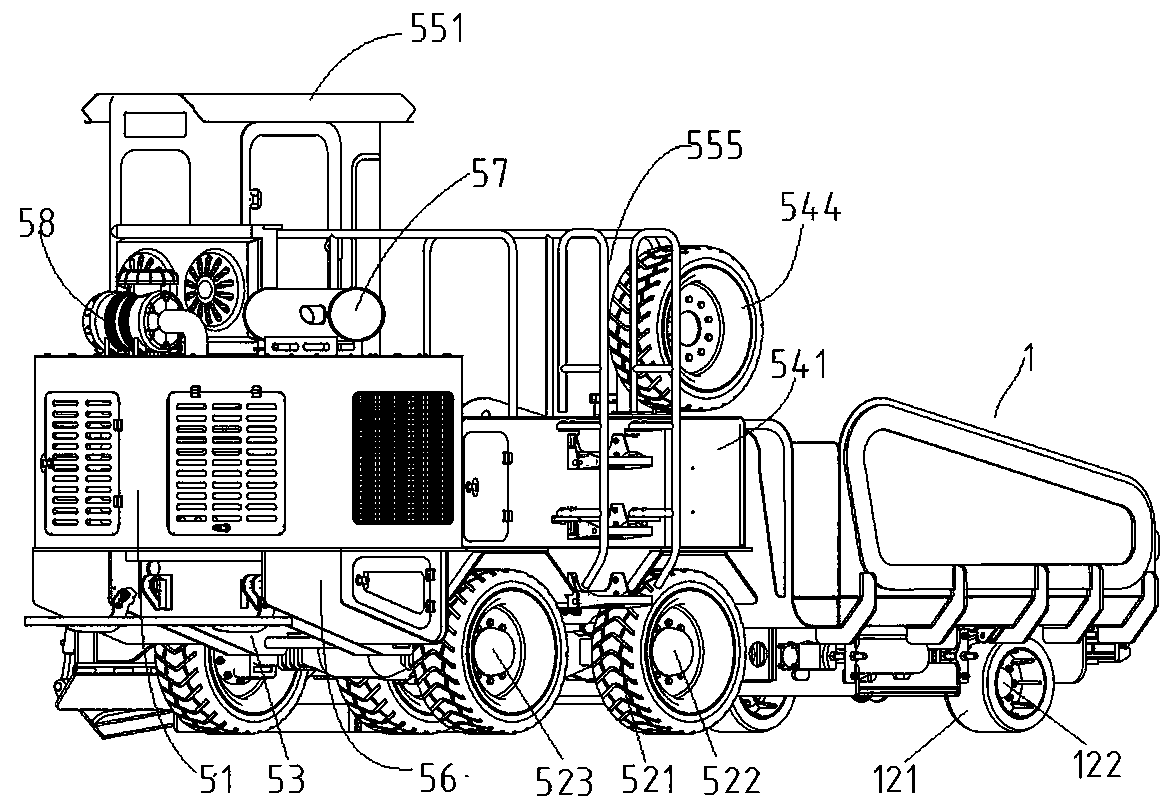

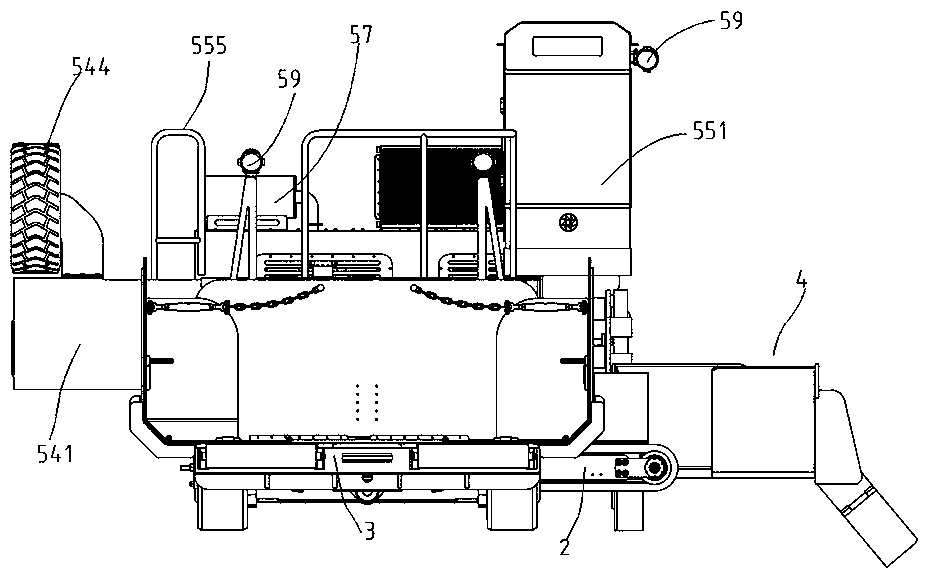

[0040] This embodiment is a soil road shoulder forming paver, which includes: a hopper assembly, a slip mold 4 and a main engine 5,

[0041] The main engine 5 includes a main engine chassis 53 and a power box 51 arranged on the main engine chassis 53; the power box 51 is provided with hydraulic pumps, hydraulic valves, gearboxes, engines and other power devices to realize the driving of the main engine 5, paving and forming, etc. Function. The rear side of the main engine chassis 53 is provided with a rear pedal 533, which is convenient for personnel to assemble, overhaul, etc. up and down. A muffler 57 and an air cleaner 58 are disposed behind the power box 51 .

[0042] The hopper assembly is arranged on the front side of the main engine 5, the hopper assembly includes a hopper 1 and a hopper underframe 13 for carrying the hopper 1, and the left side of the hopper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com