Automatic Sprinkling Maintenance System and Control Method for Expressway Concrete Guardrail

An automatic spraying, highway technology, applied in the direction of roads, roads, road safety devices, etc., can solve the problems of slow strength growth, long occupation time, increased maintenance costs, etc., to reduce the cost of using benches, avoid shrinkage cracks, Guaranteed stable growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

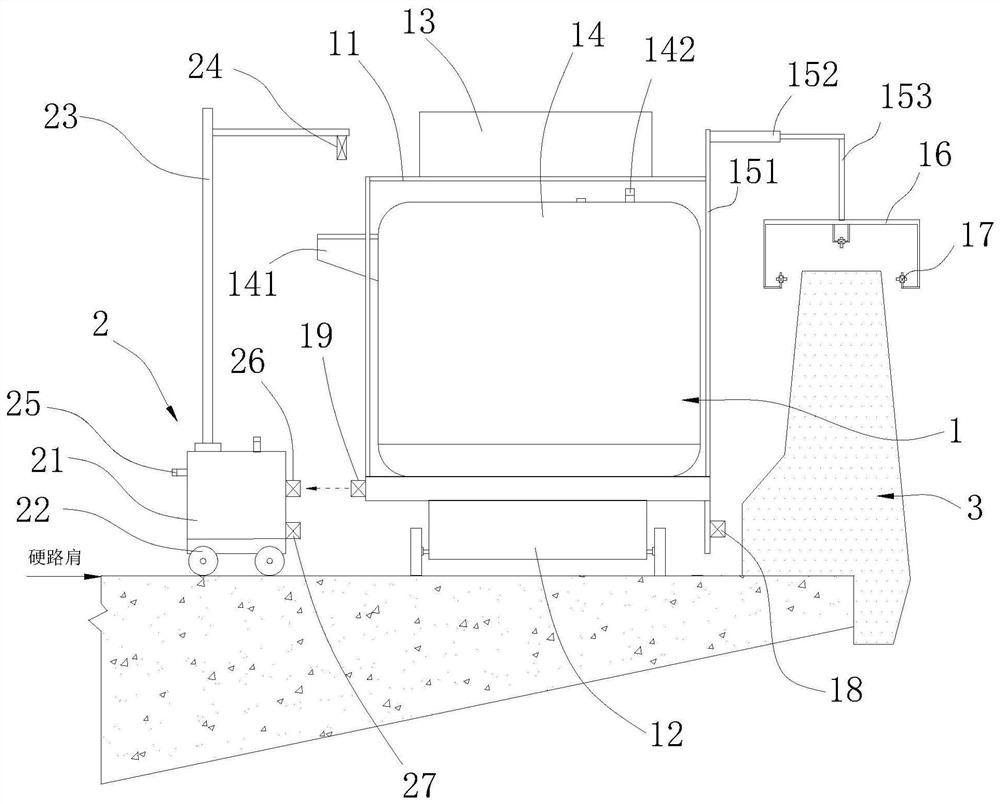

[0045] refer to figure 1 , an automatic spray maintenance system for expressway concrete guardrails, comprising an outsourced anti-collision guardrail 3, a walking spray device 1 and a water supply device 2.

[0046] The walking spray device 1 includes a vehicle frame 11, a first electric traveling mechanism 12, a water tank 14, a control box 13, and a spray frame with several shower heads 17; wherein, the first electric traveling mechanism 12 is installed on the bottom of the vehicle frame 11;

[0047] At least two first distance measuring sensors 18 are installed on the bottom of the vehicle frame 11 and toward the side of the outsourcing type anti-collision barrier 3;

[0048] The control box 13 is installed on the top of the vehicle frame 11, and the first operation panel, the first controller, the water pump and the first accumulator are installed inside it, the first electric running mechanism 12, the first operation panel, the water pump and the first measurement The d...

Embodiment 2

[0056] This embodiment provides a control method for operating and controlling the maintenance system in Embodiment 1. Specifically, the method includes:

[0057] S01. Preparation steps:

[0058] Move the water supply device 2 to the section of the outsourcing type crash barrier 3, and make the second distance measuring sensor 27 face the outsourcing type crash barrier 3; connect the water pipe to the water inlet joint 25 on the water supply device 2, and then pass The second operation panel starts the water supply device 2;

[0059] Move the walking spray device 1 to the starting point of the outsourcing type anti-collision barrier 3, so that the three nozzles 17 are respectively aligned with the inner side, the top and the outside of the outsourcing type anti-collision barrier 3, and adjust the length of the telescopic rod 152 to adjust The relative distance of the nozzles 17 located on both sides of the outsourcing type anti-collision guardrail 3; then start the walking sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com