Water-permeable concrete and preparation method thereof

A technology for permeable concrete and cementitious materials, applied in the field of building materials, can solve the problems of large fluctuation in the quality of permeable concrete, high transportation costs, waste of excess slurry, etc., and achieve the effects of improving poor water resistance, facilitating construction, and reducing transportation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

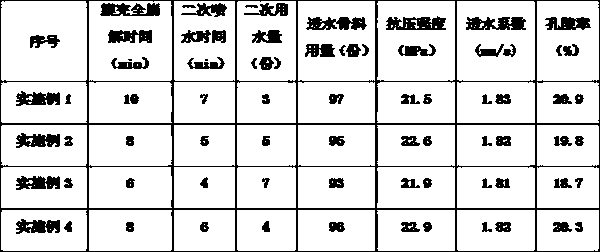

Embodiment 1

[0038] As a preferred embodiment of the present invention, the present invention includes a water-permeable aggregate for concrete, including cementitious material and aggregate, characterized in that: the outer surface of the aggregate is uniformly wrapped with cementitious material, the glue The outer surface of the gelling material is wrapped with a starch film, the starch film is formed by spraying a starch film solution with a mass fraction of 1% on the outer surface of the gelling material and then drying, and the starch film solution is obtained by dissolving modified starch in a solvent.

[0039] The solvent is 1,4-dioxane; the modified starch is obtained by esterification and modification of corn starch, and the degree of substitution of the modified starch is 1.0; the gelling material includes 94 parts of P.O42.5 cement, 5 parts of silica fume part, 0.9 part of latex powder, and 0.1 part of water reducer; the aggregate is gravel with a particle size of 10 mm.

[0040...

Embodiment 2

[0053] As another preferred embodiment of the present invention, the present invention includes a permeable aggregate for concrete, including cementitious material and aggregate, characterized in that: the outer surface of the aggregate is uniformly wrapped with cementitious material, and the The outer surface of the gelling material is wrapped with a starch film, the starch film is formed by spraying a starch film solution with a mass fraction of 3% on the outer surface of the gelling material and then drying, and the starch film solution is obtained by dissolving modified starch in a solvent.

[0054] The solvent is chloroform; the modified starch is obtained by esterification and modification of potato starch, and the degree of substitution of the modified starch is 0.5; the gelling material includes 90 parts of P.O52.5 cement, 8 parts of nano silicon dioxide, latex 1.7 parts of powder, 0.3 parts of water reducer; the aggregate is gravel with a particle size of 5 mm.

[005...

Embodiment 3

[0068] As another preferred embodiment of the present invention, the present invention includes a water-permeable aggregate for concrete, including cementitious material and aggregate, characterized in that: the outer surface of the aggregate is evenly wrapped with cementitious material, the The outer surface of the gelling material is wrapped with a starch film, the starch film is formed by spraying a starch film solution with a mass fraction of 5% on the outer surface of the gelling material and then drying, and the starch film solution is obtained by dissolving modified starch in a solvent.

[0069] The solvent is acetone; the modified starch is obtained by esterification and modification of tapioca starch, and the degree of substitution of the modified starch is 0; the gelling material includes 88 parts of P.O52.5 cement, 4 parts of nano silicon dioxide, and 6 parts of silicon powder part, 1.5 part of latex powder, and 0.5 part of water reducer; the aggregate is gravel with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com