Undersea drilling rig mud circulation system and method

A circulatory system and mud technology, applied in earth-moving drilling, wellbore/well components, flushing wellbore, etc., can solve the problem of short service life of the subsea mud circulation system, avoid pipeline blockage failure, prolong service life, Deliver reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

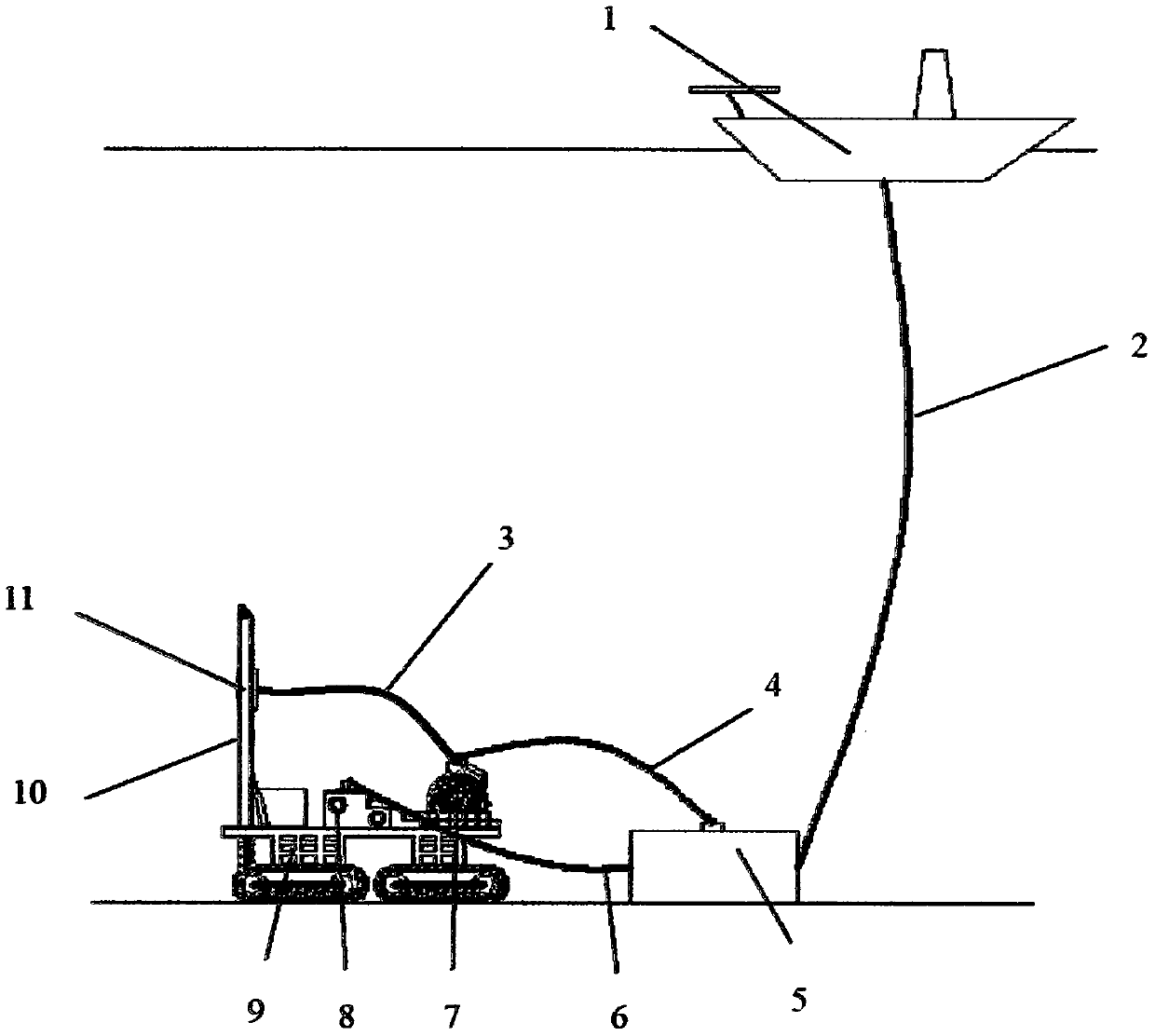

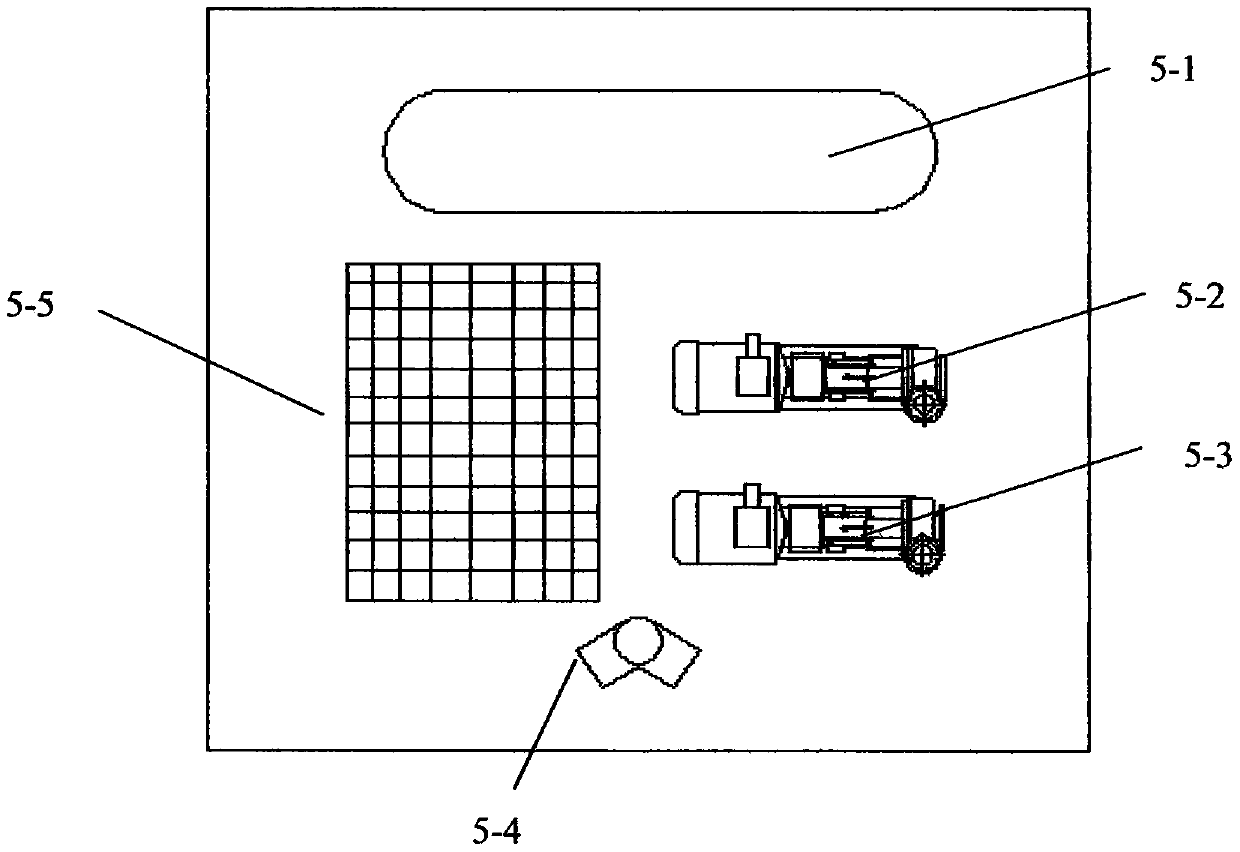

[0064] This embodiment provides a mud circulation system for a subsea drilling rig, which is especially suitable for deep-water drilling for oil or natural gas hydrate exploitation. Such as figure 1 As shown, the mud circulation system of the subsea drilling rig includes: auxiliary ship 1, umbilical cable 2, coiled tubing tension section 3, coiled tubing mud input pipeline 4, submarine mud processing device 5, wellhead mud recovery pipeline 6, coiled tubing 7, wellhead Device 8 , subsea drilling rig base 9 , injection head 11 and derrick 10 .

[0065] The auxiliary vessel 1 is located on the sea surface. One end of the umbilical cable 2 is connected with the auxiliary ship 1 , and the other end is connected with the seabed mud processing device 5 , which is used to provide a channel for injecting mud into the seabed and returning mud to the auxiliary ship 1 . Preferably, the umbilical cable contains at least three cavities, one is a power transmission cavity for placing tran...

Embodiment 2

[0074] This embodiment provides a mud circulation method for a subsea drilling rig, such as Figure 5 shown, including the following steps:

[0075] S1. Inject mud from the auxiliary vessel 1 into the coiled tubing 7;

[0076] S2. Return the mud from the wellhead device 8 to the seabed mud treatment device 5 through the wellhead mud recovery pipeline 6;

[0077] S3, the submarine mud processing device 5 performs the first filtering treatment on the mud;

[0078] S4. Return the mud processed by the seabed mud processing device 5 to the auxiliary ship 1 through the umbilical cable 2;

[0079] S5. The auxiliary ship 1 performs a second filtering process on the mud and stores it.

[0080] Preferably, the step of injecting mud from the auxiliary ship 1 into the coiled tubing 7 in S1 includes:

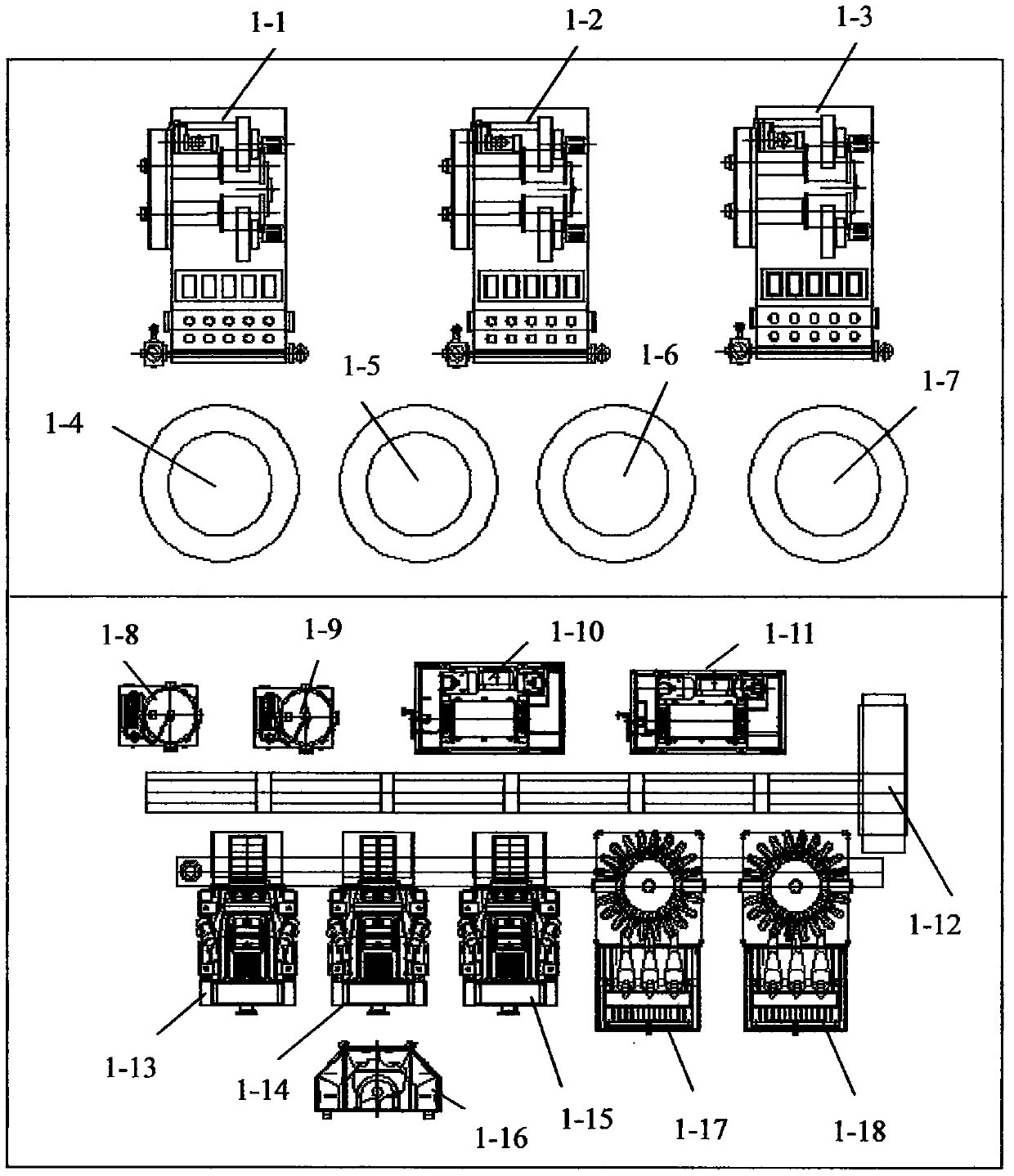

[0081] S11. Control the two mud pumps in mud pump one 1-1, mud pump two 1-2 and mud pump three 1-3 to pump the mud in the mud tank into the injection chamber of the umbilical cable 2, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com