Biomass particle combustion furnace

A technology of biomass particles and stoves, which is applied in the direction of combustion equipment, solid fuel combustion, lighting and heating equipment, etc. It can solve the problems of affecting fuel, blocking the ventilation gap of the fuel layer, and slagging, so as to solve the problem of slagging, Solve the effect of not being able to clean up the dust in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

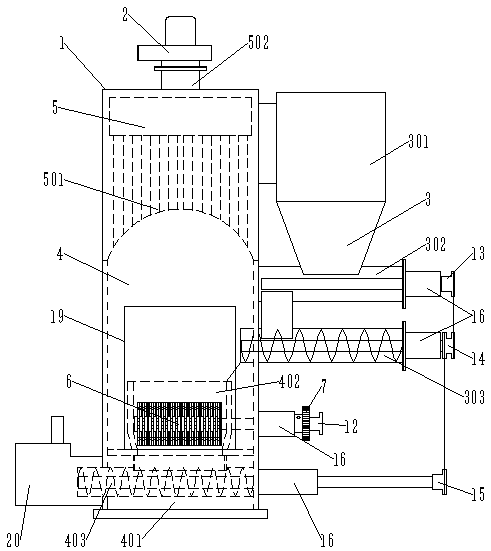

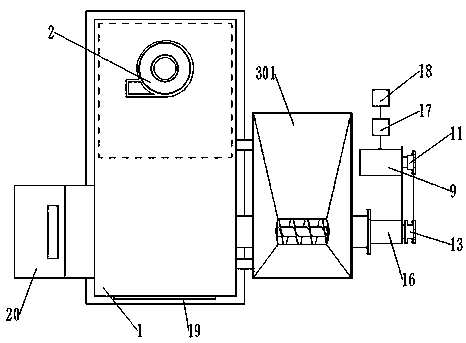

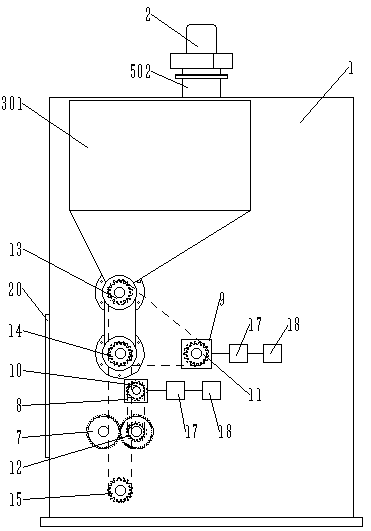

[0027] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings.

[0028] Such as Figure 1~5 As shown, the biomass particle combustion stove of the present embodiment is mainly composed of a furnace body 1, an induced draft fan 2, a feeding device 3, a storage bin 301, an upper feeding auger 302, a lower feeding auger 303, and a combustion chamber 4. Ash bin 401, ash removal auger 403, flue gas chamber 5, smoke inlet 501, smoke exhaust port 502, combustion bin 402, grate 6, shaft 601, grate teeth 602, gear 7, first motor 8. Second motor 9, first driving wheel 10, second driving wheel 11, first driven wheel 12, second driven wheel 13, third driven wheel 14, fourth driven wheel 15, support sleeve 16, time relay 17 , governor 18, furnace door 19, ash hopper 20 and spacer 21 etc. constitute.

[0029] Wherein the furnace body 1 is provided with a combustion chamber 4 and a flue gas chamber 5, the flue gas c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com