Product quality detection system and method based on opencv

A technology for detecting system and product quality, applied in image analysis, instruments, calculations, etc., can solve the problems of cumbersome operation, large work error, large workload, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

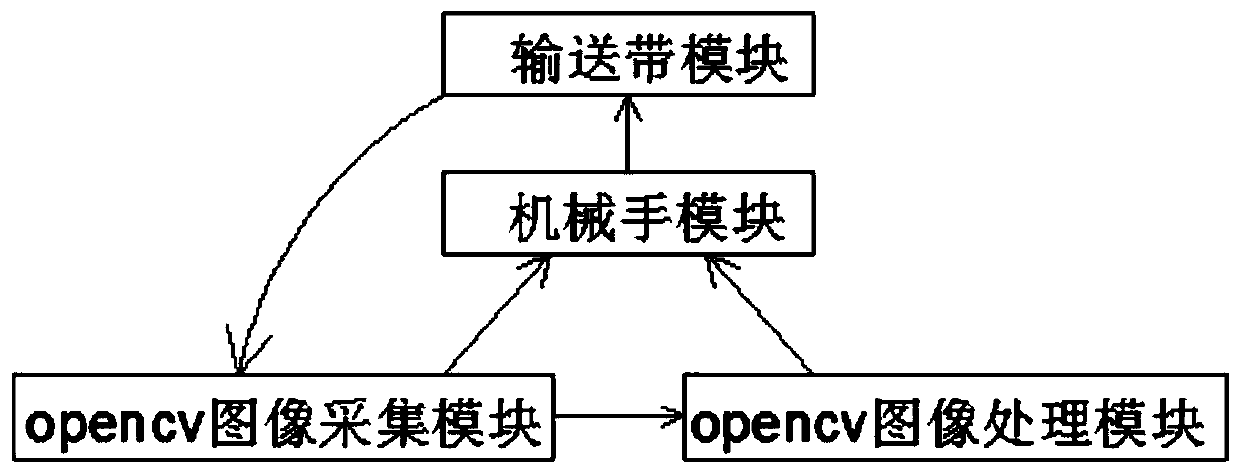

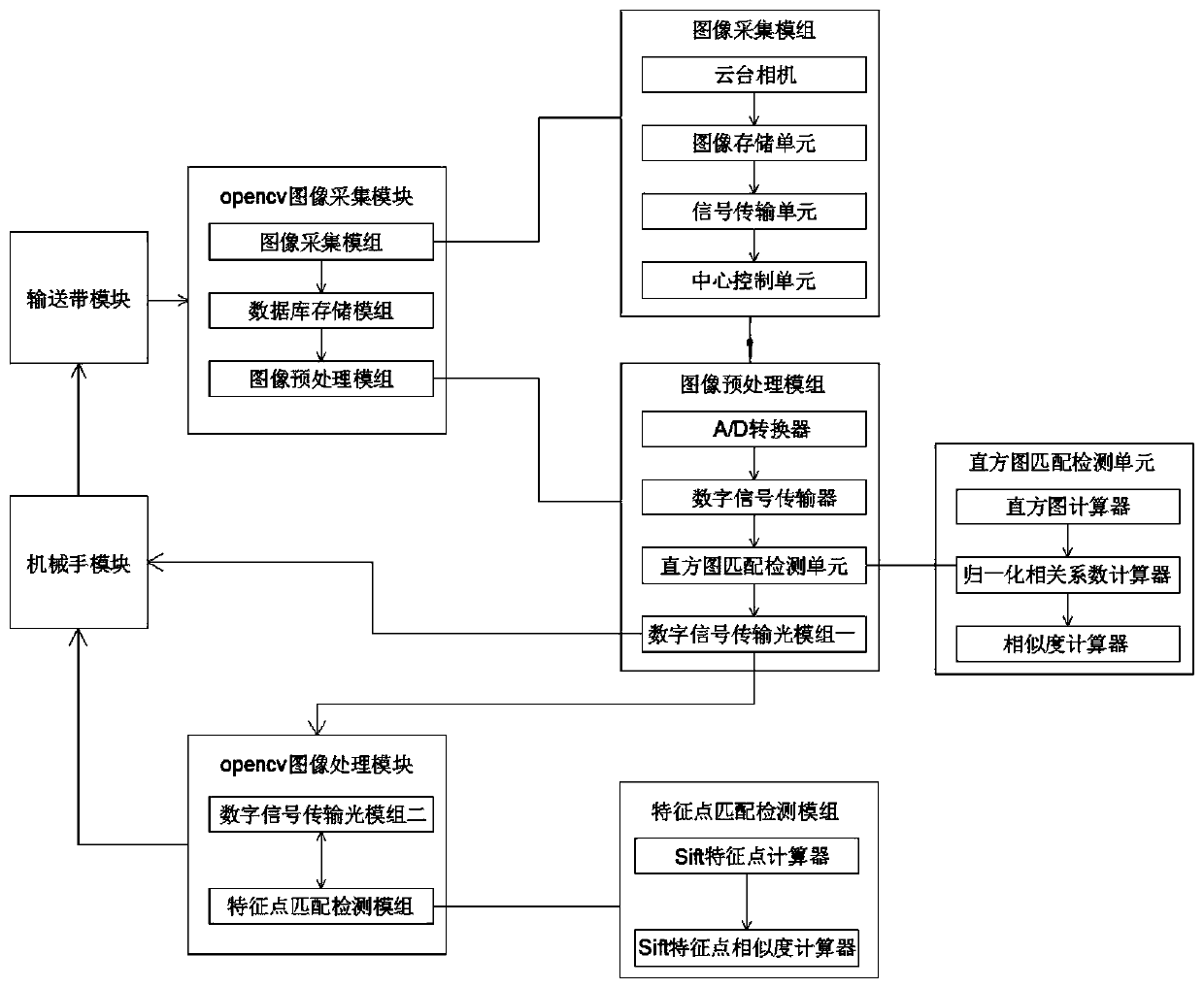

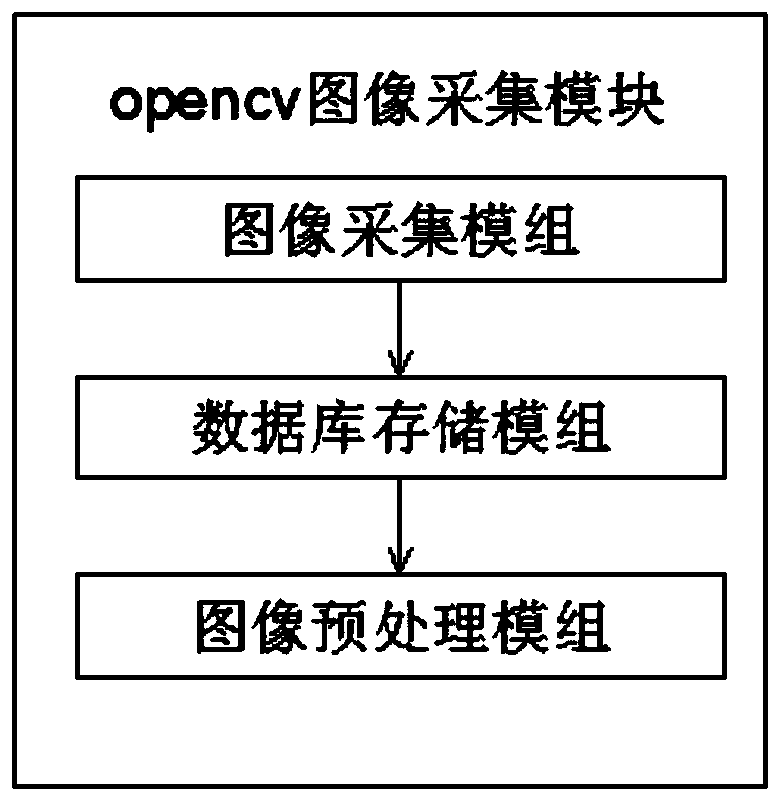

[0038] refer to Figure 1-6, a product quality inspection system based on opencv, including a conveyor belt module, an opencv image acquisition module, an opencv image processing module, a manipulator module, the first output of the opencv image acquisition module is connected to the first input of the manipulator module, and the opencv image acquisition The second output of the module is connected to the input of the opencv image processing module, the output of the opencv image processing module is connected to the second input of the manipulator module, the output of the manipulator module is connected to the input of the conveyor belt module, and the output of the conveyor belt module Connect the input end of the opencv image acquisition module, the opencv image acquisition module includes a database storage module, an image acquisition module, an image preprocessing module, and both the database storage module and the image acquisition module are electrically connected to ...

Embodiment 2

[0042] refer to Figure 1-9 , a product quality inspection system based on opencv, including a conveyor belt module, an opencv image acquisition module, an opencv image processing module, a manipulator module, the first output of the opencv image acquisition module is connected to the first input of the manipulator module, and the opencv image acquisition The second output of the module is connected to the input of the opencv image processing module, the output of the opencv image processing module is connected to the second input of the manipulator module, the output of the manipulator module is connected to the input of the conveyor belt module, and the output of the conveyor belt module Connect the input end of the opencv image acquisition module, the opencv image acquisition module includes a database storage module, an image acquisition module, an image preprocessing module, and both the database storage module and the image acquisition module are electrically connected to...

Embodiment 3

[0046] refer to figure 2 , a product quality detection system based on opencv, which is basically the same as that of Embodiment 1, and furthermore, the digital signal transmission optical module 1 is electrically connected with the digital signal transmission optical module 2, so that it is convenient to carry out the detection module through the histogram matching After the histogram similarity detection, the image information is transmitted to the opencv image processing module to facilitate the feature point similarity matching detection, and the digital signal transmission optical module 1 and the digital signal transmission optical module 2 are electrically connected to the manipulator module They are connected to facilitate the operation of the manipulator module controlled by the digital signal transmission optical module 1 and the digital signal transmission optical module 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com