Design and preparation methods of magnetic tunnel junction based on Fe3N/GaN heterostructure

A magnetic tunnel junction and heterostructure technology, applied in the field of information industry, can solve the problems of low spin injection efficiency, mismatch between ferromagnetic electrodes and insulating conductance, etc., and achieve the effect of improving spin injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

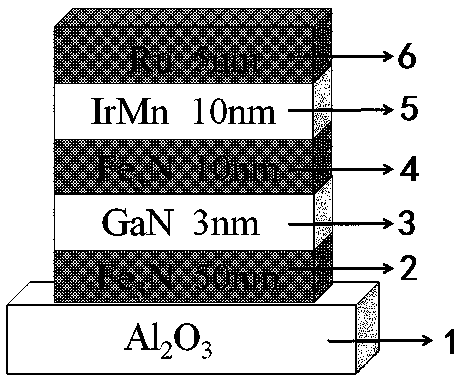

[0019] Based on Fe 3 Design and preparation method of a magnetic tunnel junction of N / GaN heterostructure, the design of the magnetic tunnel junction includes a substrate 1, and a ferromagnetic electrode 2, a barrier layer 3, and a ferromagnetic electrode sequentially arranged on the substrate 4. Pinning layer 5, protective layer 6.

[0020] Described preparation method comprises the steps:

[0021] In step 1, a (0006)-oriented single-crystal sapphire film is used as a substrate 1, and it is cleaned with alcohol in an ultrasonic cleaner for 5 minutes.

[0022] Step 2, on the sapphire substrate 1 in step 1, utilize the magnetron sputtering method to sputter a layer of (002) oriented Fe 3 N thin film, as the ferromagnetic electrode 2. Among them, the purity of the iron target is not less than 99.99%, and the condition is that the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com