Silicon through-electrode void-free filling method and copper plating solution used in filling method

A technology of penetrating electrodes and filling methods, which is applied in the field of electroplating of silicon penetrating electrodes, can solve the problems of incomplete plating in the plating process, long time for penetrating electrodes, and occurrence of defects, so as to shorten filling time, reduce voids, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

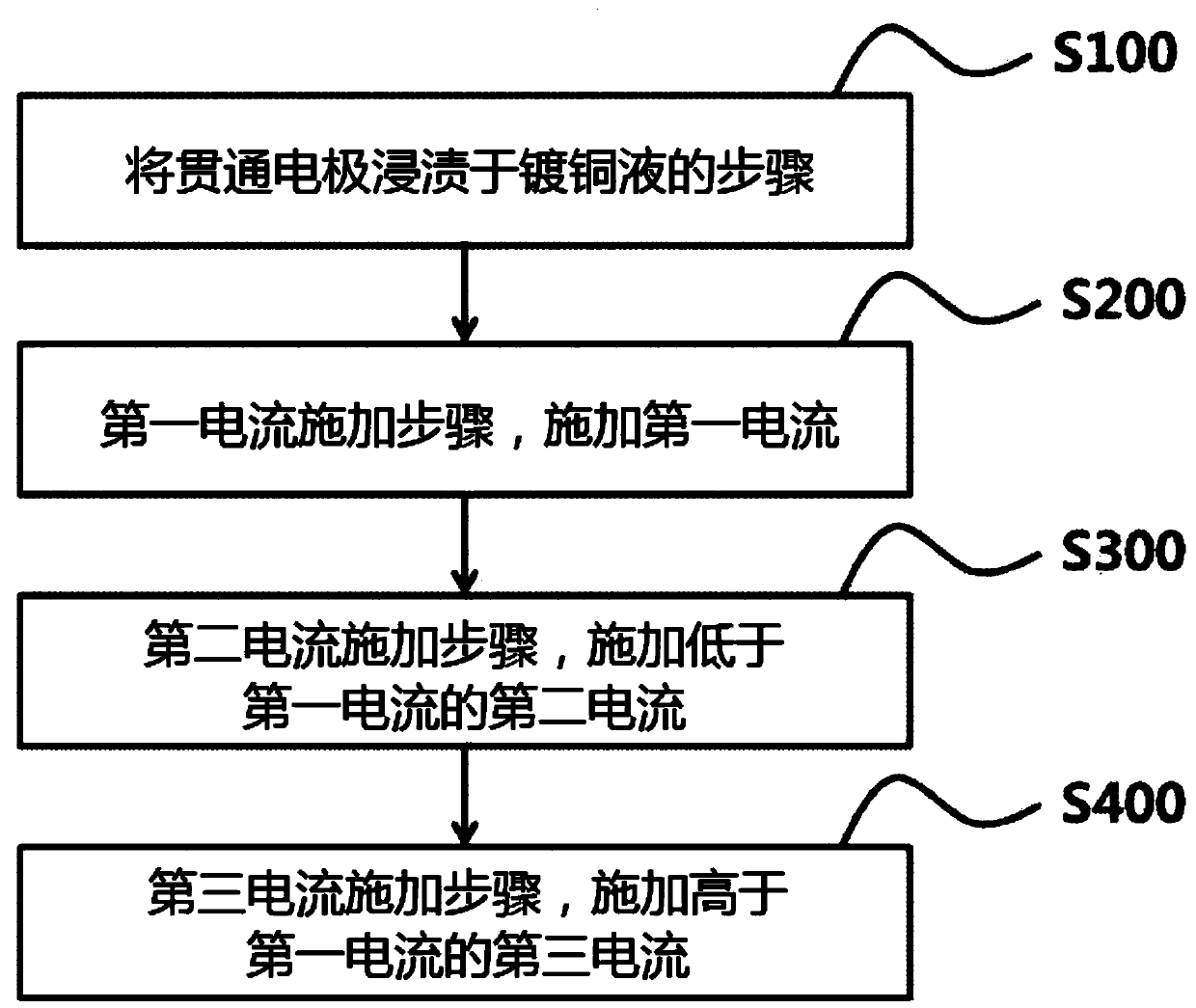

Method used

Image

Examples

preparation example 1

[0105] Under the conditions of Comparative Example 1, only the current application conditions were changed, and the filling experiment was performed under the current application conditions mentioned in Table 4 below. The amount of current consumed in Comparative Example 1 and Preparation Example 1 was the same.

[0106] Table 4

[0107] Current application conditions of Preparation Example 1

[0108] condition

Current Density (ASD)

Current application time (second, s)

apply the first current

1.1

30

apply the second current

0.2

200

Apply a third current

1.5

620

[0109] (ASD=Ampere per Square Deci-meter, A / dm 2 )

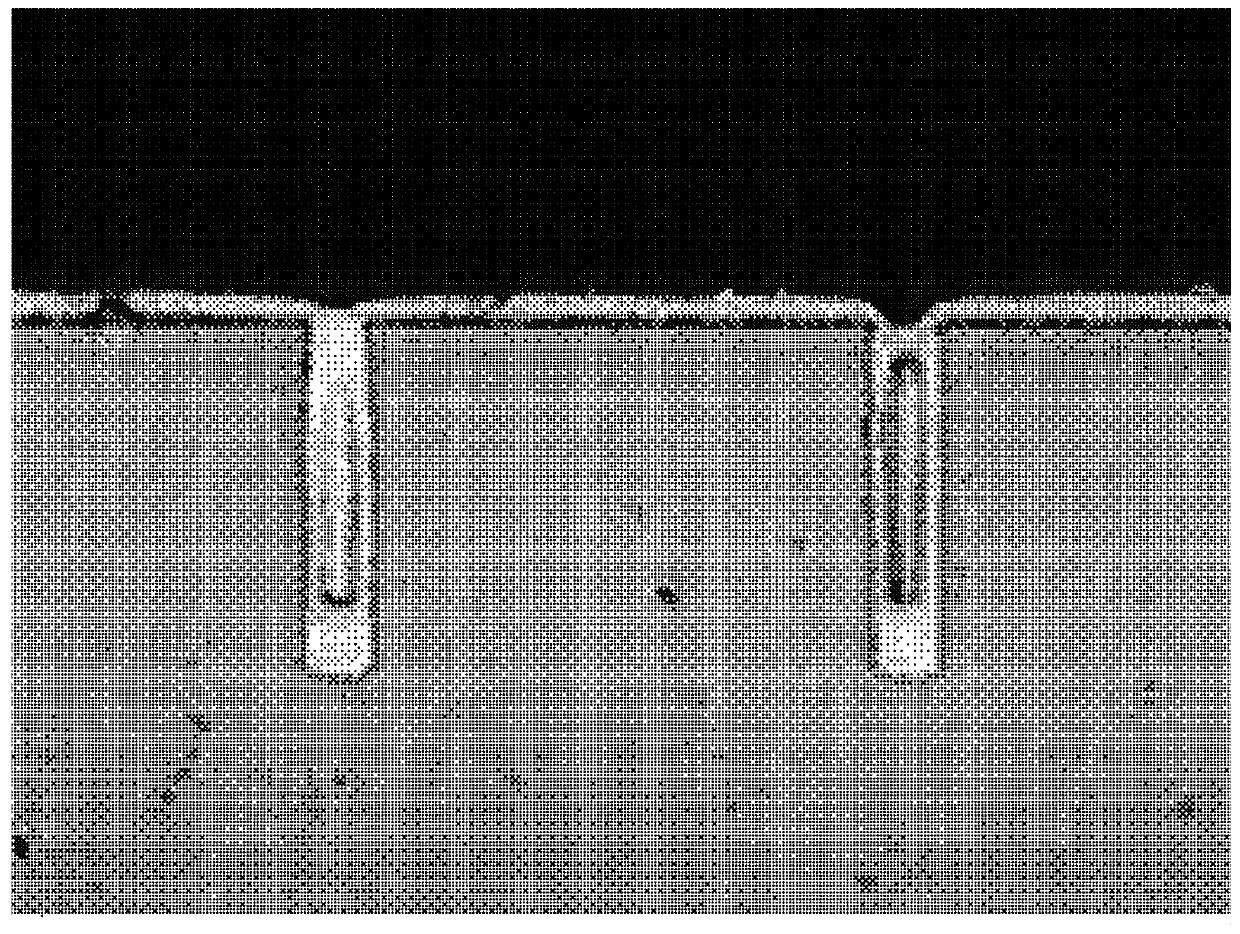

[0110] Figure 5 A cross-section of a via plated by the conditions is shown in . Depend on Figure 5 It was confirmed that in the case of the three-step current application method, the through-holes were filled without defects in the through-electrodes.

[0111] Further, when comparing Comparative E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com