Crack plugging agent based on nano-micron fibers for drilling fluid and preparation method

A technology of microfibers and nanofibers, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve problems such as wellbore instability, improve temperature resistance, improve stability and wellbore stability, and facilitate The effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

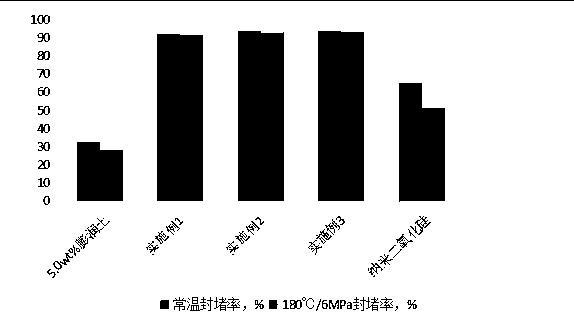

Examples

Embodiment example

[0031] A nano-micron fiber-based crack plugging agent for drilling fluids, comprising the following components in parts by mass: 32-37 nanofibers, 6-7 dispersants, and 57-61 micron fibers. Among them: the nanofibers and microfibers are derived from bagasse; bagasse is the residue after sugar cane is squeezed. Sugar cane is mainly produced in subtropical regions such as Guangxi and Guangdong, and its main components are vitamins, fats, protein organic acids, and calcium. , iron and other substances. The dispersant is one of sodium dioctyl sulfosuccinate, sodium trioctyl sulfosuccinate, sodium dioctyl sulfosuccinate or any combination of two.

[0032] The specific preparation method of the aforementioned drilling fluid based on nano-microfiber fracture plugging agent comprises the following steps:

[0033] 1. Pretreatment of bagasse:

[0034] (1) Clean the bagasse with deionized water, dry it, and press it with a press for several times in a row. After squeezing out all the suga...

Embodiment 1

[0043] (1) Add 1000 mL of deionized water to a high-pressure homogenizer, add 130 g of nanofibers in batches, homogenize at 18,000 rpm for 1 hour, add 20 g of dispersants (such as sodium dioctyl sulfosuccinate, trioctyl Sodium sulfosuccinate, sodium dioctyl sulfosuccinate or a combination of any two), homogenize at 480rpm for 18min; (2) Slowly add 200g of micron fibers into the above homogenizer , homogenized for 48 minutes at 480rpm; (3) Dry the above product at 80±5°C, and use a pulverizer to crush the dried product to 800~1000 mesh, that is, to obtain nano-micron fiber cracks plugging agent.

Embodiment 2

[0045] (1) Add 1000mL of deionized water to the high-pressure homogenizer, add 150g of nanofibers in batches, homogenize at 22000rpm for 1.5h, add 30g of dispersant (such as sodium dioctyl sulfosuccinate, trioctyl Sodium sulfosuccinate, sodium dioctyl sulfosuccinate, or any combination of two), homogenize at 500rpm for 20min; (2) Slowly add 300g micron Fiber, homogenized for 50min at 500rpm; (3) Dry the above product at 80±5°C, and use a pulverizer to crush the dried product to 800~1000 mesh to obtain nano-micron fiber Crack plugging agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com