Sulfur separating and discharging device for high-sulfur gas field

A high-sulfur gas field technology, applied in the direction of loading/unloading, transportation and packaging, mining fluids, etc., can solve the problems of reducing the effective flow area of pipelines, complex pipeline networks, and blockage of downstream gathering and transportation pipelines, so as to eliminate the risk of natural gas poisoning , safe and convenient operation, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

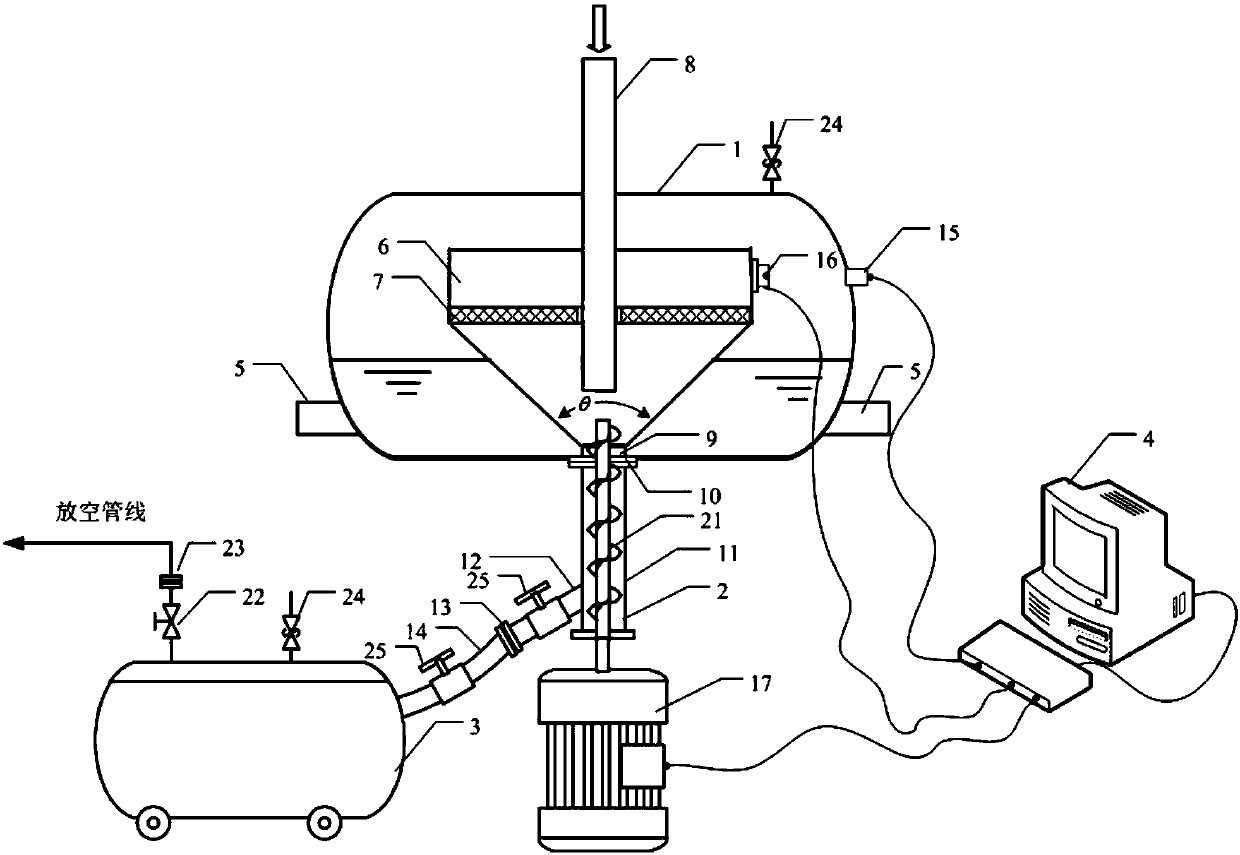

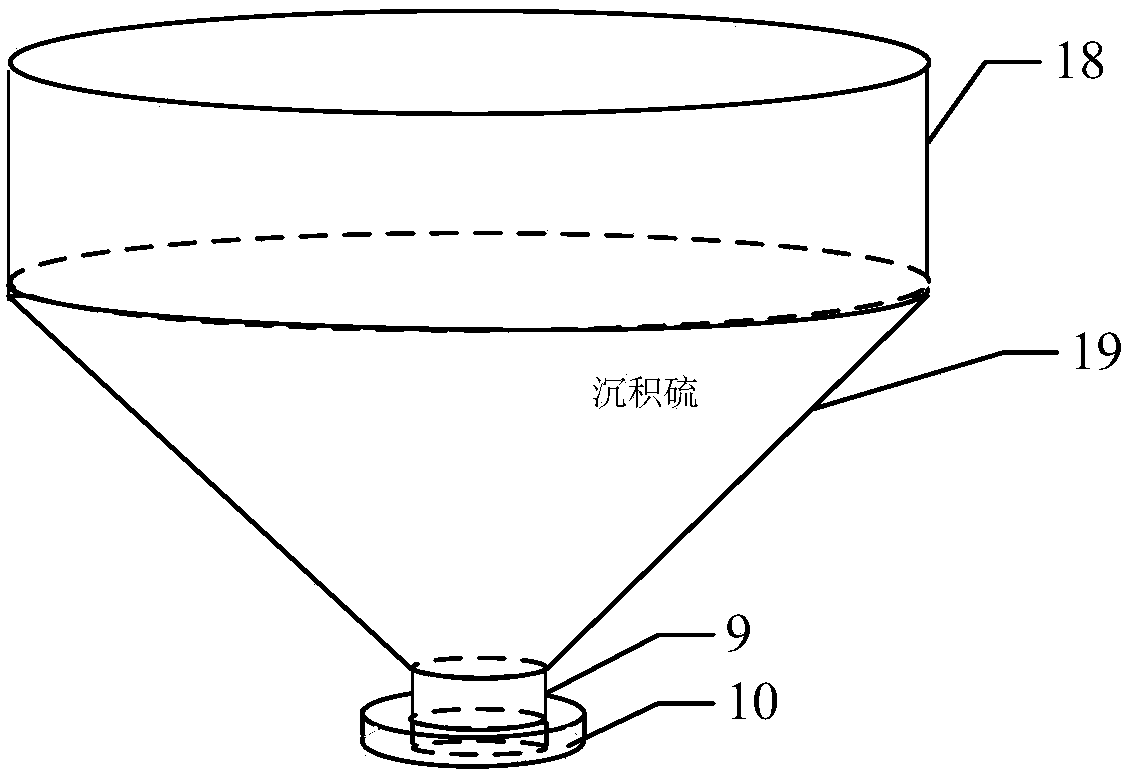

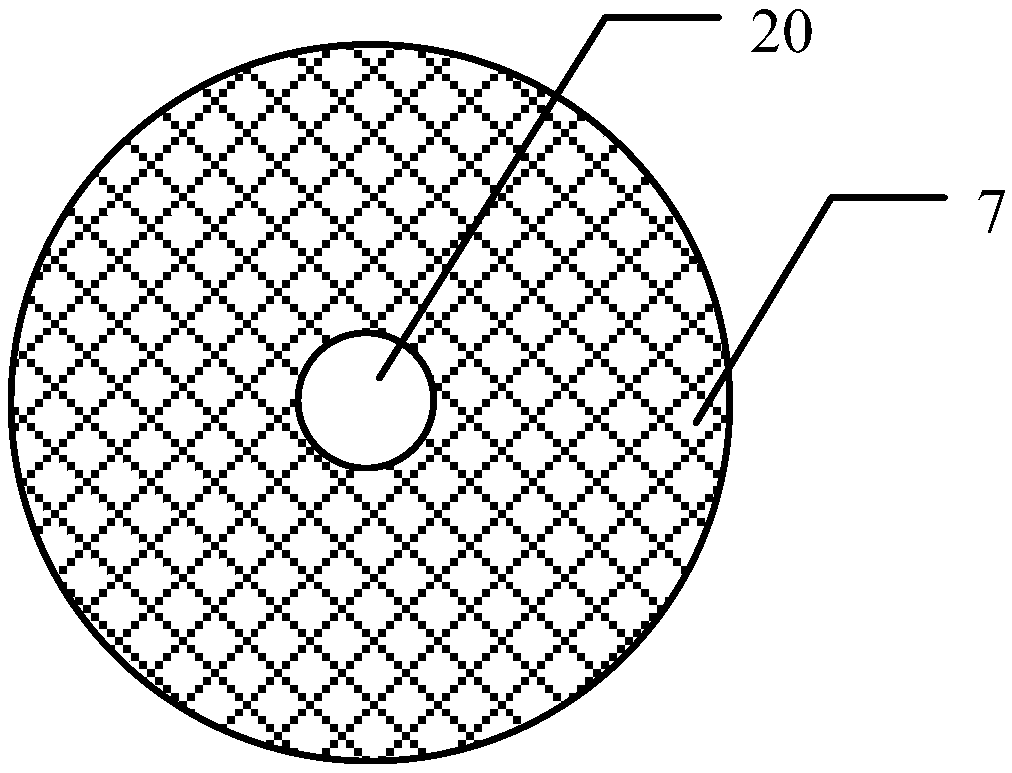

[0025] like figure 1 As shown, a sulfur separation and desulfurization device for a high-sulfur gas field is characterized in that it mainly includes a liquid-solid separation tank 1, a screw sulfur conveyer 2, a sulfur tank truck 3, and a data acquisition control module 4. The liquid-solid separation tank 1 is a horizontal Type high-pressure vessel, the left and right ends of the liquid-solid separation tank 1 are respectively provided with a drain pipe 5 near the bottom, the inside of the liquid-solid separation tank is provided with a sulfur accumulating chamber 6, and the sulfur accumulating chamber 6 is provided with a sulfur barrier 7, and the inlet of the sulfur-water mixture The pipe 8 passes through the guide hole 20 of the sulfur barrier 7 from the top of the liquid-solid separation tank to the inside of the sulfur accumulating chamber 6, and the sulfur outlet 9 at the bottom of the sulfur accumulating chamber 6 is transported through the connecting flange 10 and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com