Seven-series aluminum alloy small piece and die casting method thereof

A technology of aluminum alloy and small parts, which is applied in the field of seven-series aluminum alloy small parts and their die-casting. It can solve the problems of complex shape and structure, voids, and the decline of the overall strength of the product, and achieve the effect of high material strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

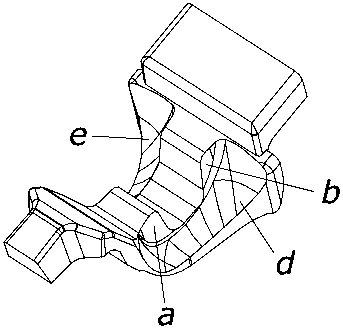

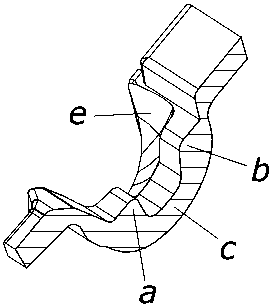

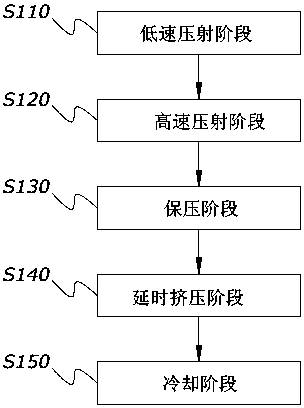

[0038] The specific embodiments and examples of the present invention will be described in detail below in conjunction with the accompanying drawings. The described specific embodiments are only used to explain the present invention, and are not intended to limit the specific embodiments of the present invention.

[0039] The seven-series aluminum alloy raw material used in the seven-series aluminum alloy small piece die-casting method of the present invention refers to the seven-series aluminum alloy raw material with a model number of 7K03, and the non-AL components contained in it and their weight percentage contents are: Zn4.90~ 5.10%, Mg1.75~1.85%, Fe0.050~0.085%, Cu0.025~0.055%, Zr0.03~0.05%, Si≤0.05%, Mn≤0.02%, Cr≤0.02%, Ti≤0.025% , V≤0.02%, Ga≤0.02%, Sn≤0.02%; it can not only meet the fluidity requirements of die-casting, but also effectively improve the material strength of die-casting parts.

[0040] The addition of zinc element to aluminum alone has a very limited i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com