Electromagnet driving low-pressure casting molding heat balance device

An electromagnetic drive, low-pressure casting technology, applied in the field of low-pressure casting, can solve problems such as poor effect, difficulty in ensuring continuous operation of equipment, and unbalanced system temperature, so as to increase thermal conductivity, increase thermal resistance, and reduce heat dissipation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the embodiments.

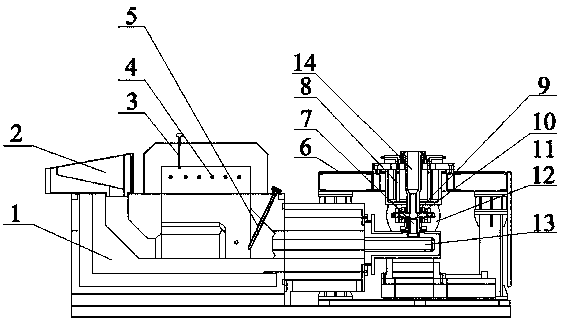

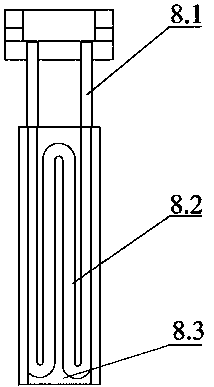

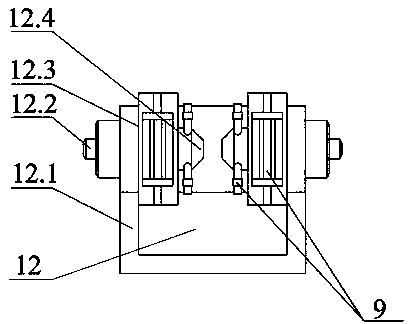

[0014] Electromagnetic drive low-pressure casting heat balance device, including holding furnace 1, electromagnetic drive pump body 6, electric field generator 11, magnetic field generating device 12 and water cooling mechanism 9, the upper part of holding furnace 1 is provided with feeding port 2, and the top of holding furnace 1 is provided with radiation Type heating device 4, the top of holding furnace 1 is interspersed with furnace atmosphere thermocouple 3, the lower part of holding furnace 1 is provided with an opening, and a thermocouple 5 near the water outlet is inserted obliquely above the opening, and the opening is connected with aluminum liquid chute 13 of electromagnetically driven pump body 6, There is an opening on the top of the aluminum liquid chute 13, and a rise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com