A cold runner mold

A cold runner and mold technology, applied in the field of cold runner molds, can solve the problems of difficulty in controlling the uniformity of rubber material blanking, waste of rubber material, etc., to improve the uniformity of discharge, improve economic benefits, and have strong controllability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

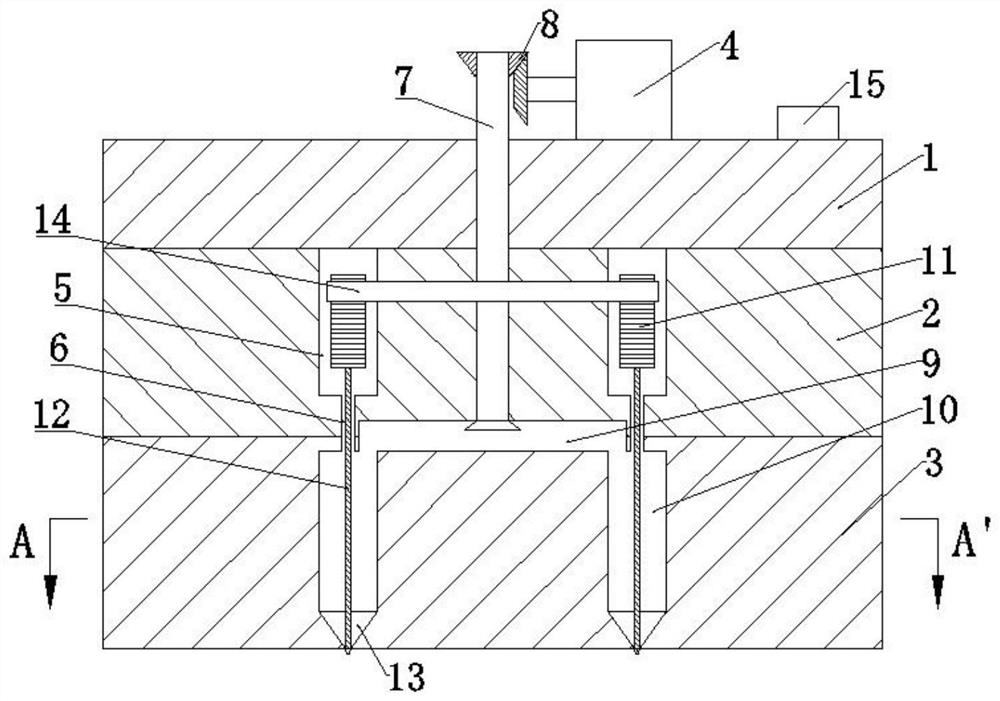

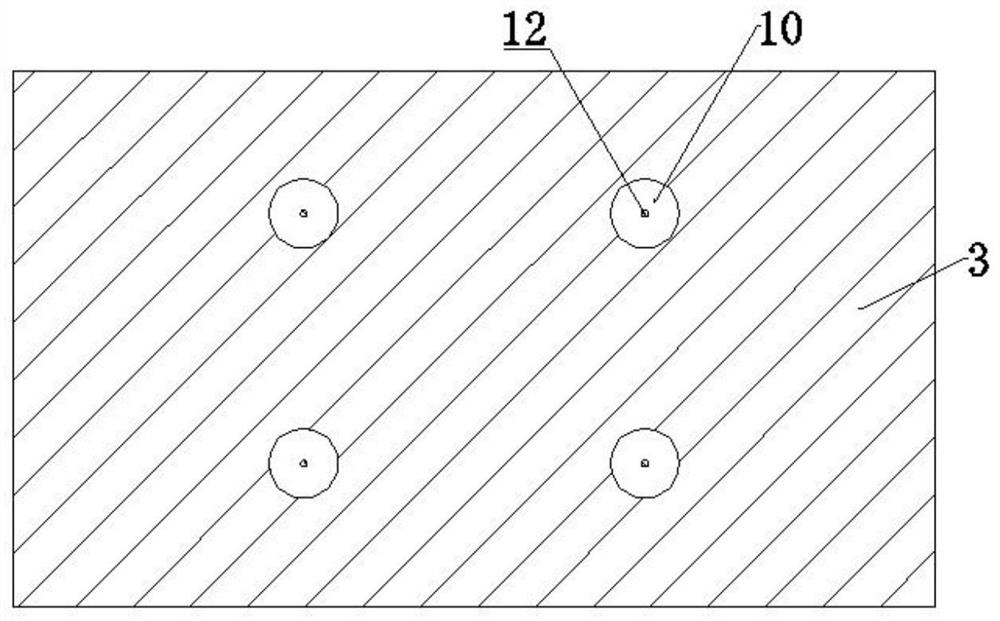

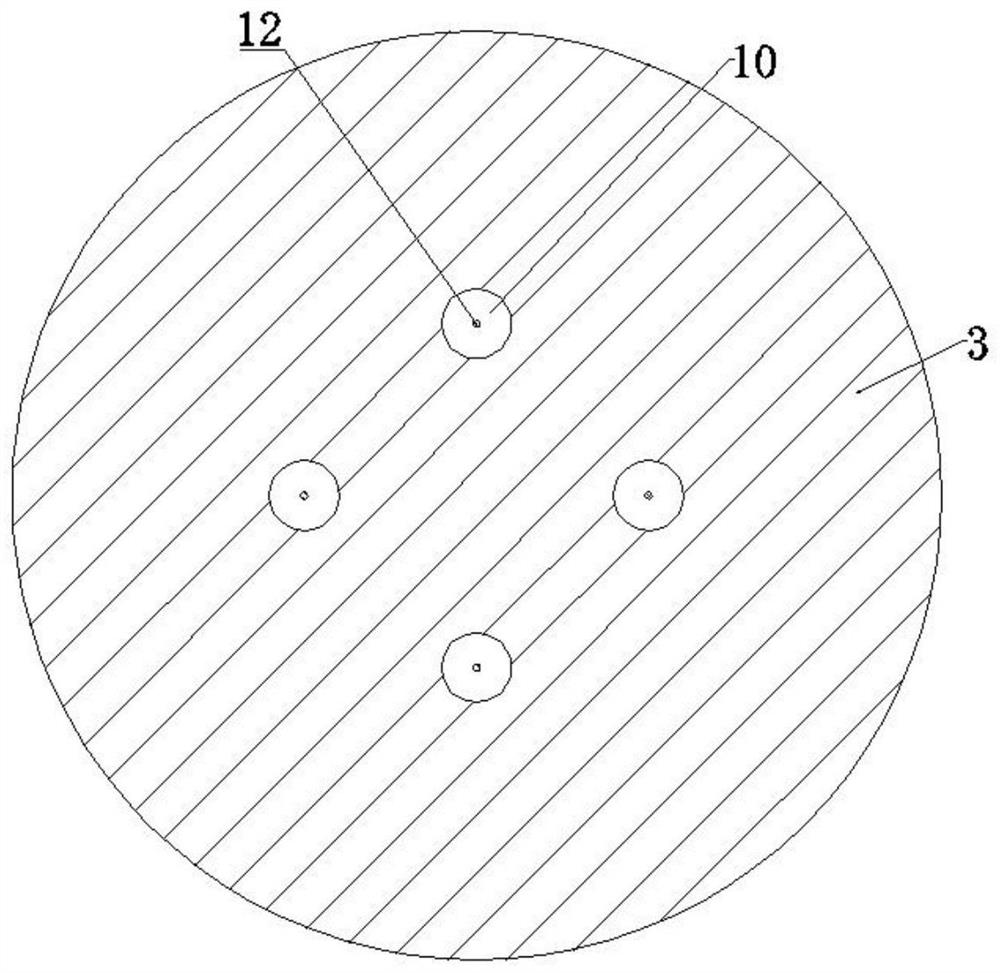

[0027] A cold runner mold in this embodiment includes an upper mold 1, a middle mold 2, a lower mold 3 and a forward and reverse motor 4, and is characterized in that: a shaft hole is set at the center of the upper mold 1, and a lifting cavity 5 is set on the middle mold 2 , the rod chamber 6 is set at the bottom of the lifting chamber 5; the injection shaft 7 is set in the shaft hole, the positive and negative motor 4 is fixed on the upper surface of the upper mold 1, and the output shaft of the positive and negative motor 4 is connected to the injection through the reversing gear set 8 Axis 7; injection hole is set at the center of injection axis 7, and shunt chamber 9 is set at the connection between upper end surface of upper mold 1 and upper end surface of middle mold 2; cold runner 10 is set in lower mold 3, injection hole, shunt chamber 9 and The cold runner 10 is connected; the lifting chamber 5 is provided with a threaded rod 11, and the center of the bottom surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com