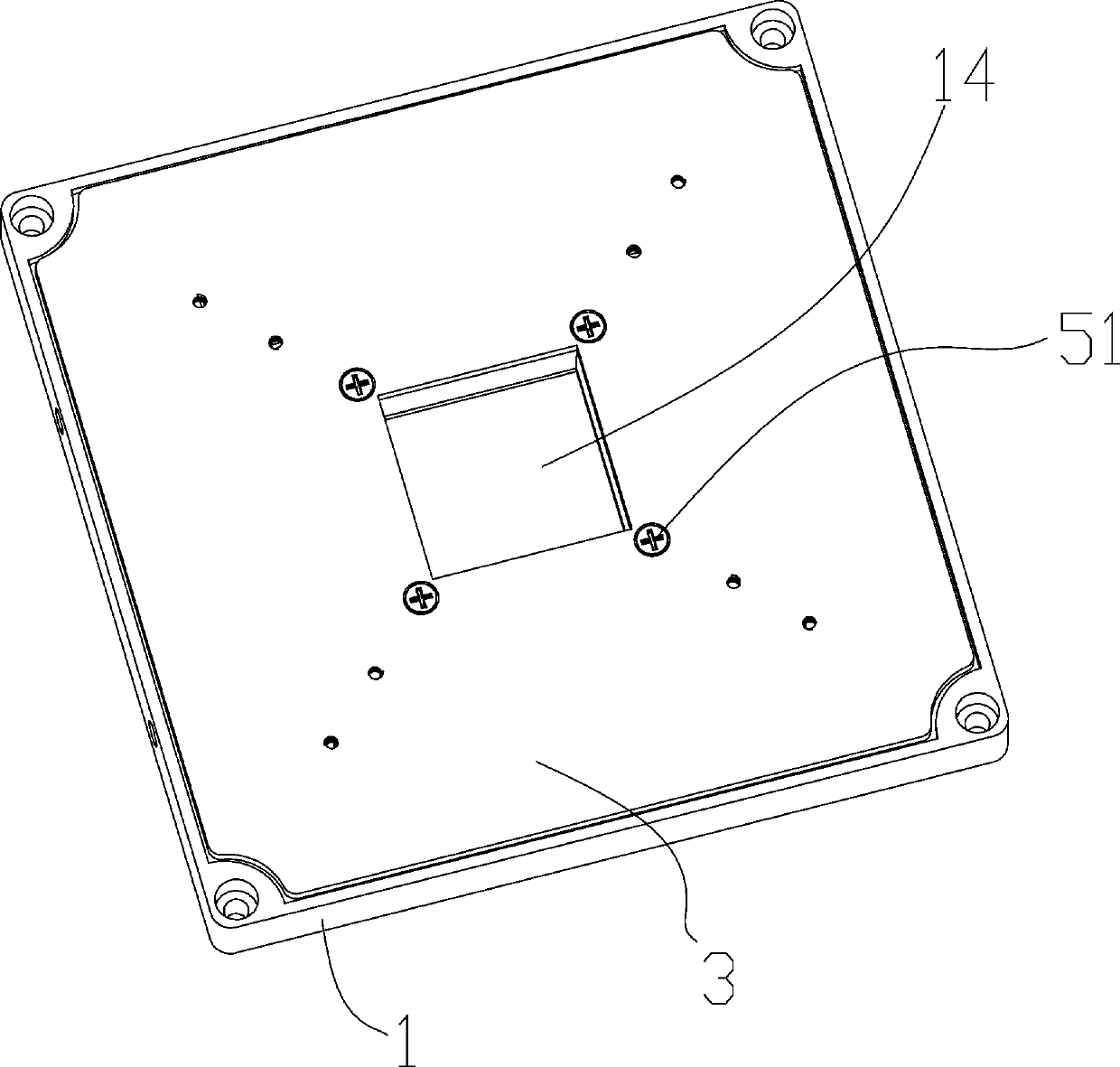

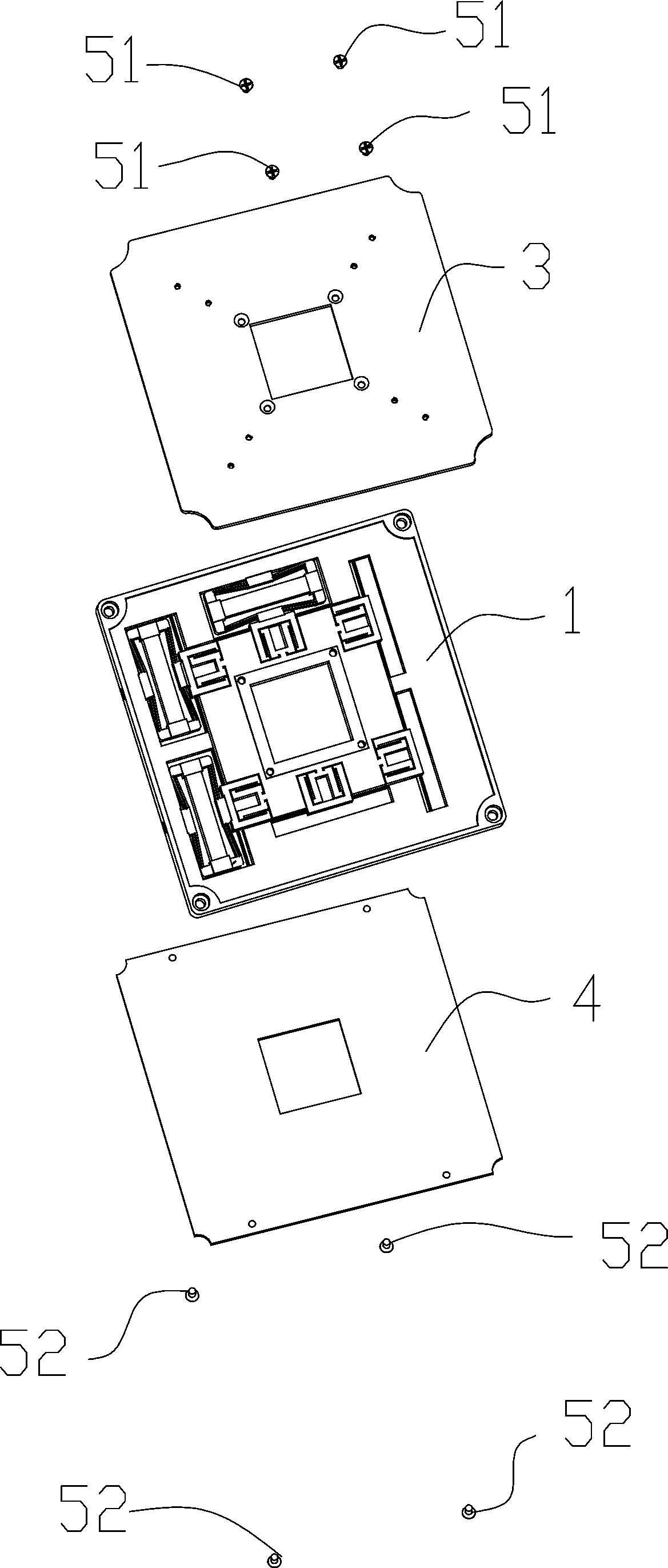

Two-translation one-rotation large-stroke uncoupled parallel piezoelectric micro-motion platform

A technology of micro-movement platform and large stroke, which is applied in the field of micro-displacement mechanism, two translations and one rotation and large stroke without coupling in parallel piezoelectric micro-movement platform, which can solve the problems of complex parallel structure, small work surface and low natural frequency. , to achieve the effect of simple and compact structure, large working table, and enlarged displacement stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

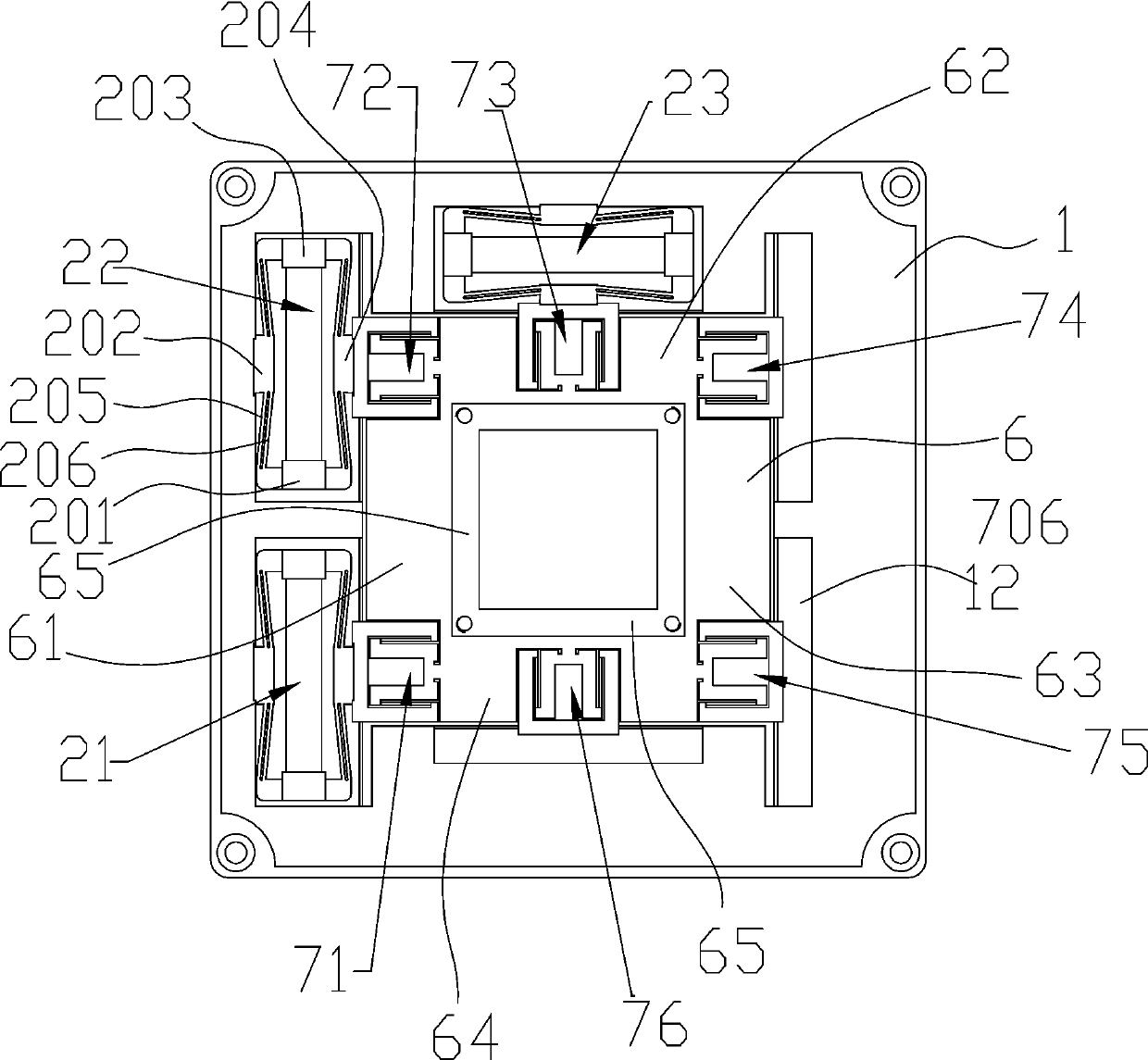

Embodiment 1

[0047] The first conduction part 71 to the sixth conduction part 76 of the first embodiment have two second receiving grooves 701, two rigid parts 703, and the first convex part 704, the second convex part 702 and the second convex part 702. The number of a flexible thin plate 705 is 2 and it is arranged between two adjacent rigid parts 703, and the two adjacent rigid parts 703 are integrally formed at one end located in the third receiving groove 12, Between the adjacent rigid parts 703, there is a hollow groove for screwing the screws into the fourth rigid block 204, such as Figure 9 shown.

Embodiment 2

[0048] The difference between Embodiment 2 and Embodiment 1 is that the fourth conducting portion 74 to the sixth conducting portion 76 of Embodiment 2 do not have hollow grooves, such as Figure 10 shown.

Embodiment 3

[0049] The difference between Embodiment 3 and Embodiment 1 is that the number of second receiving grooves 701 of the fourth conduction part 74 to the sixth conduction part 76 of Embodiment 3 is one, the number of rigid parts 703 is one, and the first The number of the convex part 704, the second convex part 702 and the first flexible thin plate 705 are respectively 2 and are respectively arranged on both sides of the rigid part 703, such as Figure 11 shown.

[0050] The first rigid block 201, the second rigid block 202, the third rigid block 203, the fourth rigid block 204, the third flexible thin plate 205 and the fourth flexible thin plate 206 are composed of a bridge-type amplifying mechanism 2 integrally formed structure; fixed platform The body 11 , the second flexible thin plate 706 , the rigid portion 703 , the first convex portion 704 , the first flexible thin plate 705 , the second convex portion 702 and the moving table body 6 are integrally formed. Let the z-axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com