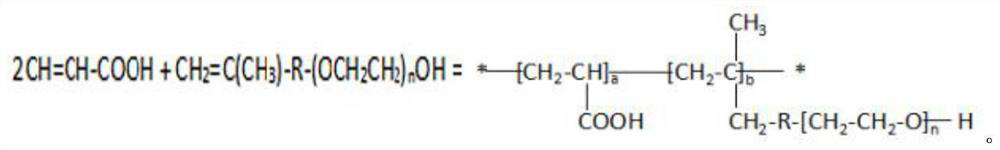

A kind of mixed alcohol polyoxyethylene ether superplasticizer macromonomer and its preparation method and application

A technology of alcohol polyoxyethylene ether and water reducer, which is applied in the field of mixed alcohol polyoxyethylene ether water reducer macromonomer, can solve the problems of low water reducing rate and flow retention, and achieve stable reaction temperature control, The effect of stabilizing temperature and avoiding safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

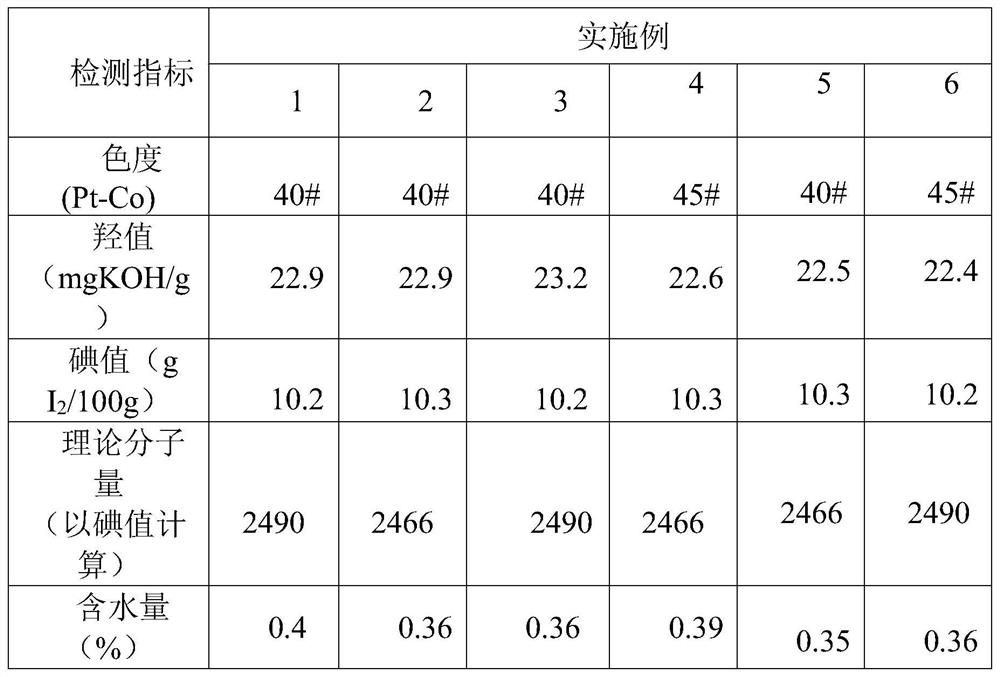

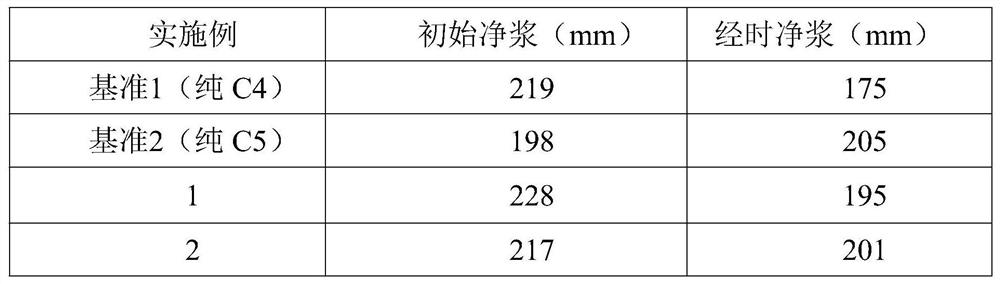

Examples

Embodiment 1

[0027] A preparation method of a mixed alcohol polyoxyethylene ether water reducer macromonomer, comprising the following steps:

[0028] 1) In the mixed raw material composed of 89.1 g of initiator methallyl alcohol and 15.72 g of isopentenol, first add 3.02 g of potassium hydroxide, after the potassium hydroxide is completely dissolved, then add 1.24 g of sodium metal, and wait until After the sodium metal is completely dissolved, a homogeneous mixed solution is formed. Shake the obtained mixed solution into the reactor, start the reactor to stir, adjust the rotation speed to 215r / min, replace the air in the reactor with nitrogen repeatedly for three times, heat the mixed solution in the reactor, and heat the temperature in the reactor to about 85°C Then start vacuuming, control the vacuum degree in the reactor to -0.1MPa, then replace the air in the reactor with nitrogen repeatedly three times, and backfill nitrogen for the last time until the pressure in the reactor is 0.0...

Embodiment 2

[0031] Repeat the step process of embodiment 1, difference is:

[0032] Step 1) In the process of synthesizing the mixed alcohol polyoxyethylene ether intermediate, the feeding quality of methallyl alcohol, isopentenol, potassium hydroxide and metal sodium is 92.45g, 10.27g, 2.95g and 1.21g respectively, The total amount of ethylene oxide introduced was 752g, and 857.47g of crude mixed alcohol polyoxyethylene ether intermediate was finally prepared.

[0033] Step 2) Take 240.66 g of the crude mixed alcohol polyoxyethylene ether intermediate prepared in step 1) to synthesize the mixed alcohol polyoxyethylene ether. During the process of synthesizing the mixed alcohol polyoxyethylene ether product, the total amount of ethylene oxide introduced was 722g, and 962.66g of the mixed alcohol polyoxyethylene ether was finally prepared.

Embodiment 3

[0035] Repeat the step process of embodiment 1, difference is:

[0036] Step 1) In the process of synthesizing the mixed alcohol polyoxyethylene ether intermediate, the feeding quality of methallyl alcohol, isopentenol, potassium hydroxide and metal sodium is 83.22g, 11.35g, 2.76g and 1.13g respectively, The total amount of ethylene oxide introduced was 694g, and 791.17g of the crude product of the mixed alcohol polyoxyethylene ether intermediate was finally prepared.

[0037] Step 2) Take 253.2 g of the crude mixed alcohol polyoxyethylene ether intermediate prepared in step 1) to synthesize the mixed alcohol polyoxyethylene ether. During the process of synthesizing the mixed alcohol polyoxyethylene ether product, the total amount of ethylene oxide introduced was 759.1 g, and 1012.3 g of mixed alcohol polyoxyethylene ether was finally prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com