Low-strength and high tenacity SA387Gr11C11 steel plate and production method thereof

A production method and high-toughness technology, applied in the field of metallurgy, can solve the problems that the yield strength cannot meet the design requirements and the strength requirements are low, and achieve the effects of low cost, stable mechanical properties, and moderate strength of the steel plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

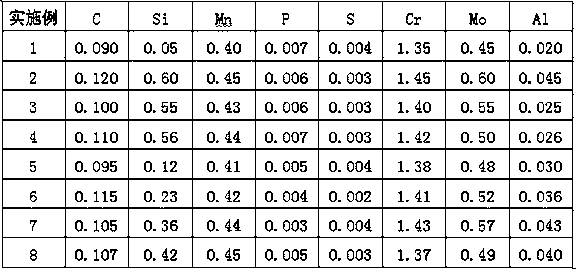

[0016] The low-strength and high-toughness SA387Gr11Cl1 steel plate in this example has a thickness of 28mm, and its chemical composition and mass percentage are shown in Table 1.

[0017] The production method of the low-strength and high-toughness SA387Gr11Cl1 steel plate of this embodiment comprises steelmaking, heating, rolling, and heat treatment operations, and the specific process steps are as follows:

[0018] (1) Steelmaking process: LF seat bag feeds aluminum wire 0.7㎏ / t steel, controls Al: 0.020% in the whole process, maintains the VD vacuum process for 15 minutes, maintains the large argon flow rate of 70NL / min for 10 minutes, and maintains the minimum argon flow rate of 25NL / min in the later stage of vacuum. The argon flow is maintained for 5 minutes; after vacuum, soft blowing is performed for 13 minutes, and the pressure of soft blowing is 0.27MPa;

[0019] (2) Billet heating process: the billet heating temperature is 1250°C, the heating coefficient is 11min / cm,...

Embodiment 2

[0024] The low-strength and high-toughness SA387Gr11Cl1 steel plate in this example has a thickness of 30 mm, and its chemical composition and mass percentage are shown in Table 1.

[0025] The production method of the low-strength and high-toughness SA387Gr11Cl1 steel plate of this embodiment comprises steelmaking, heating, rolling, and heat treatment operations, and the specific process steps are as follows:

[0026] (1) Steelmaking process: LF seat bag feeds aluminum wire 0.9㎏ / t steel, controls Al: 0.045% in the whole process, maintains 20min in the VD vacuum process; maintains a large argon flow rate of 100NL / min for 13min, and maintains a minimum flow rate of 60NL / min in the later stage of vacuum. The flow of argon gas is kept for 7 minutes; after vacuum, soft blowing is performed for 17 minutes, and the pressure of soft blowing is 0.29MPa;

[0027] (2) Billet heating process: the billet heating temperature is 1230°C, the heating coefficient is 9.0min / cm, and rolling is c...

Embodiment 3

[0032] The low-strength and high-toughness SA387Gr11Cl1 steel plate in this example has a thickness of 34mm, and its chemical composition and mass percentage are shown in Table 1.

[0033] The production method of the low-strength and high-toughness SA387Gr11Cl1 steel plate of this embodiment comprises steelmaking, heating, rolling, and heat treatment operations, and the specific process steps are as follows:

[0034] (1) Steelmaking process: LF seat bag feeds aluminum wire 0.75㎏ / t steel, controls Al: 0.025% in the whole process, maintains 17min in the VD vacuum process; maintains a large argon flow rate of 80NL / min for 11min, and maintains a minimum of 40NL / min in the later stage of vacuum. The flow of argon is maintained for 6 minutes; after vacuum, soft blowing is performed for 15 minutes, and the pressure of soft blowing is 0.28MPa;

[0035] (2) Billet heating process: the billet heating temperature is 1240°C, the heating coefficient is 10min / cm, and rolling is carried out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com