Optimization structure of combined foam flow field for solid oxide electrolysis tank

A solid oxide, optimized structure technology, applied in the direction of electrolysis components, electrolysis process, electrodes, etc., can solve the problems of large transmission resistance and uneven distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The principle and structure of the present invention will be described in detail below in conjunction with the accompanying drawings and specific examples. The present implementation that needs to be explained is descriptive rather than restrictive, and is not intended to limit the protection scope of the present invention.

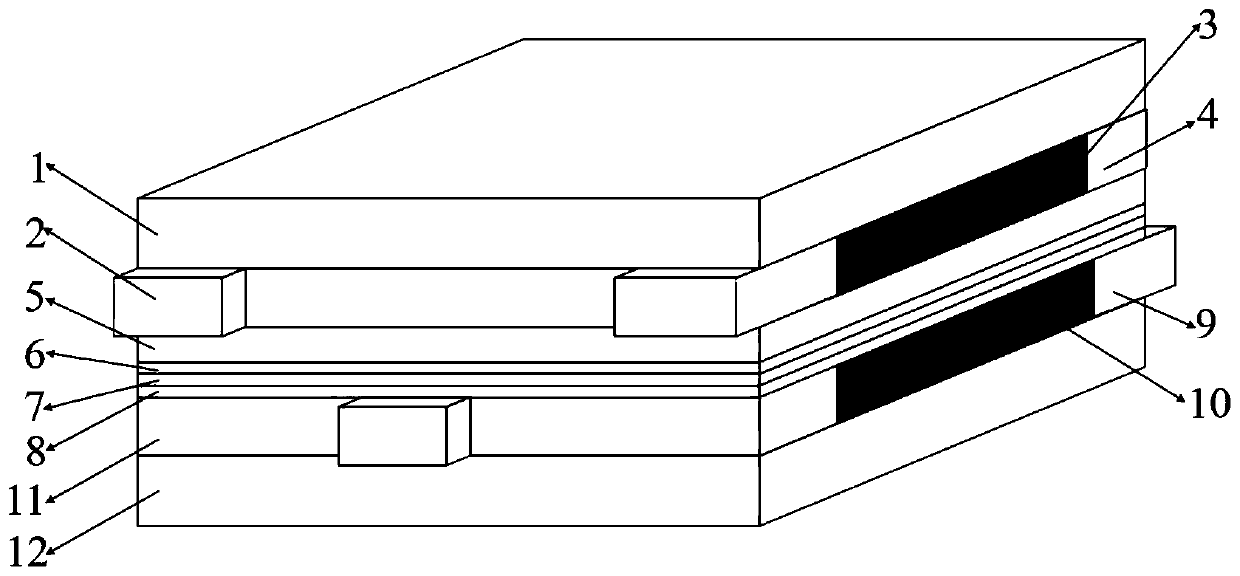

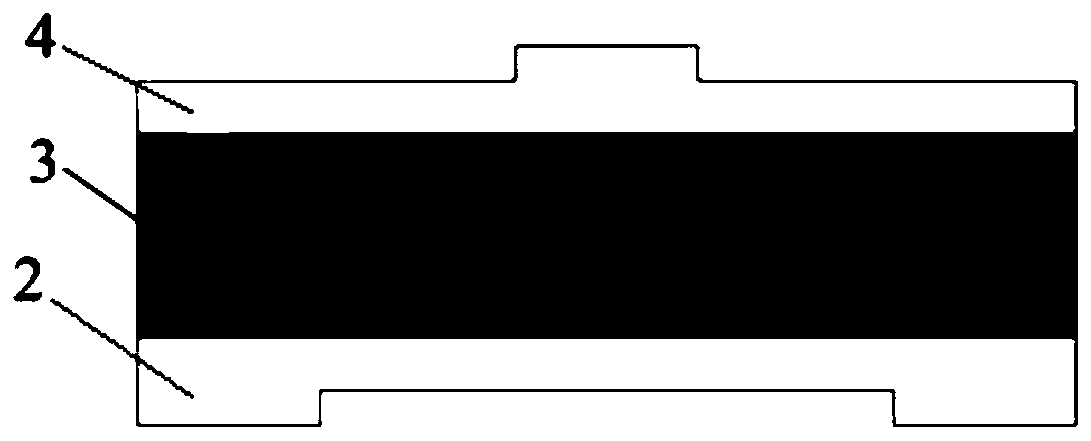

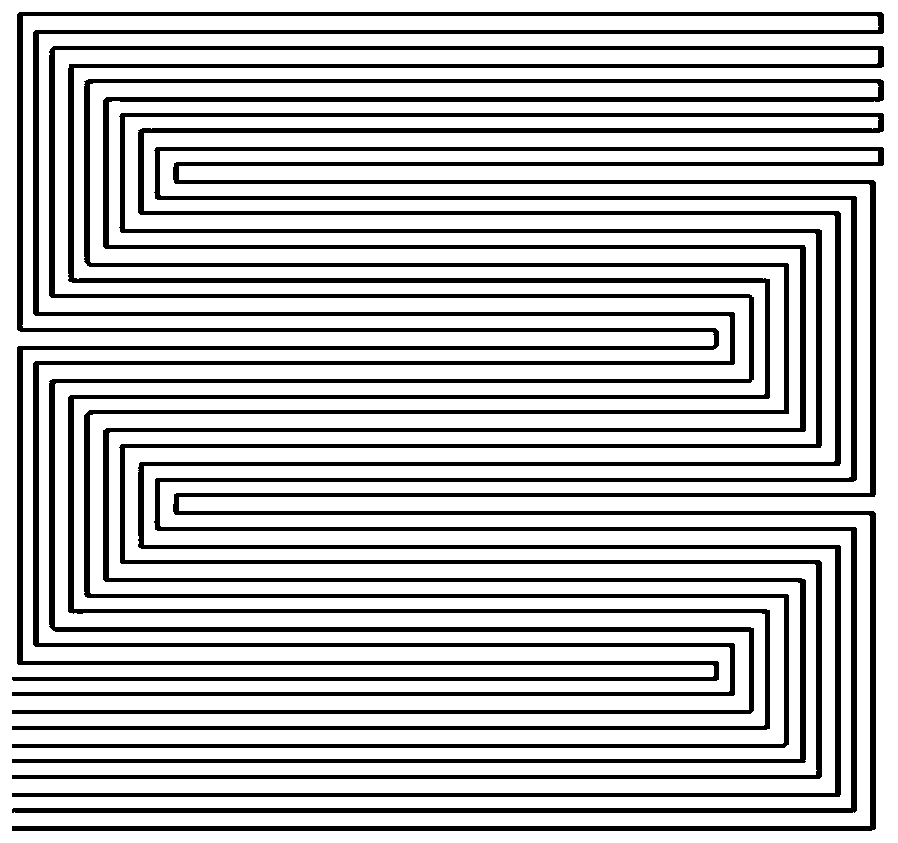

[0020] The optimized structure of the solid oxide electrolytic cell combined foam flow field (such as figure 1 ), which is characterized in that the cathode inlet cavity distribution area 2, the cathode metal foam 3 and the cathode outlet gathering area 4 are sequentially connected horizontally to form a cathode flow field (such as figure 2 ), and the flow field is placed between the cathode bipolar plate 1 and the cathode gas diffusion layer 5. The anode inlet cavity distribution area 9 , the anode metal foam 10 and the anode outlet accumulation area 11 are sequentially connected horizontally to form an anode flow field, and the flow field is pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com