Textile machine and method for automatically applying thread at working station of textile machine

A technology of textile machinery and workstations, applied in the field of automatic wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

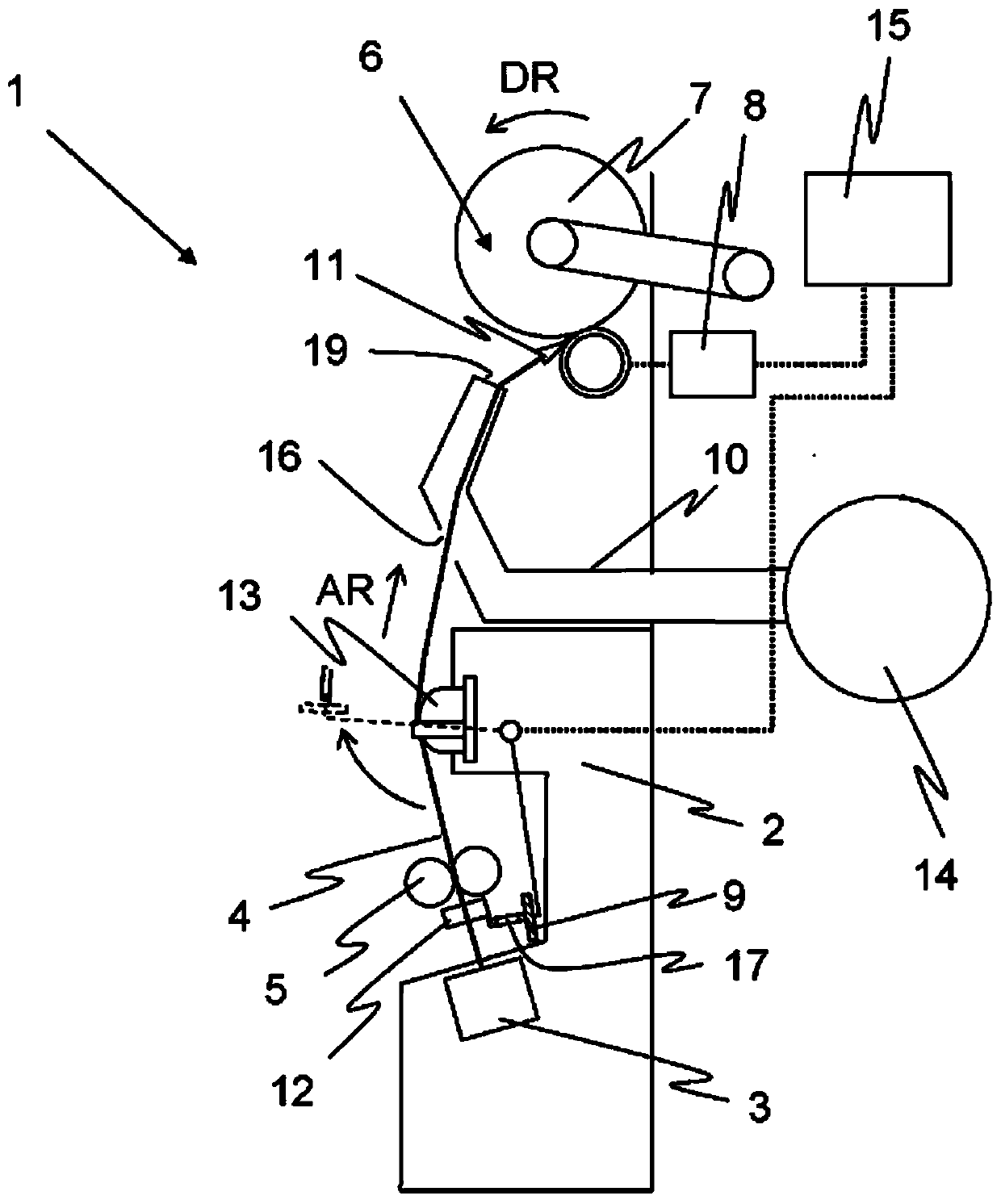

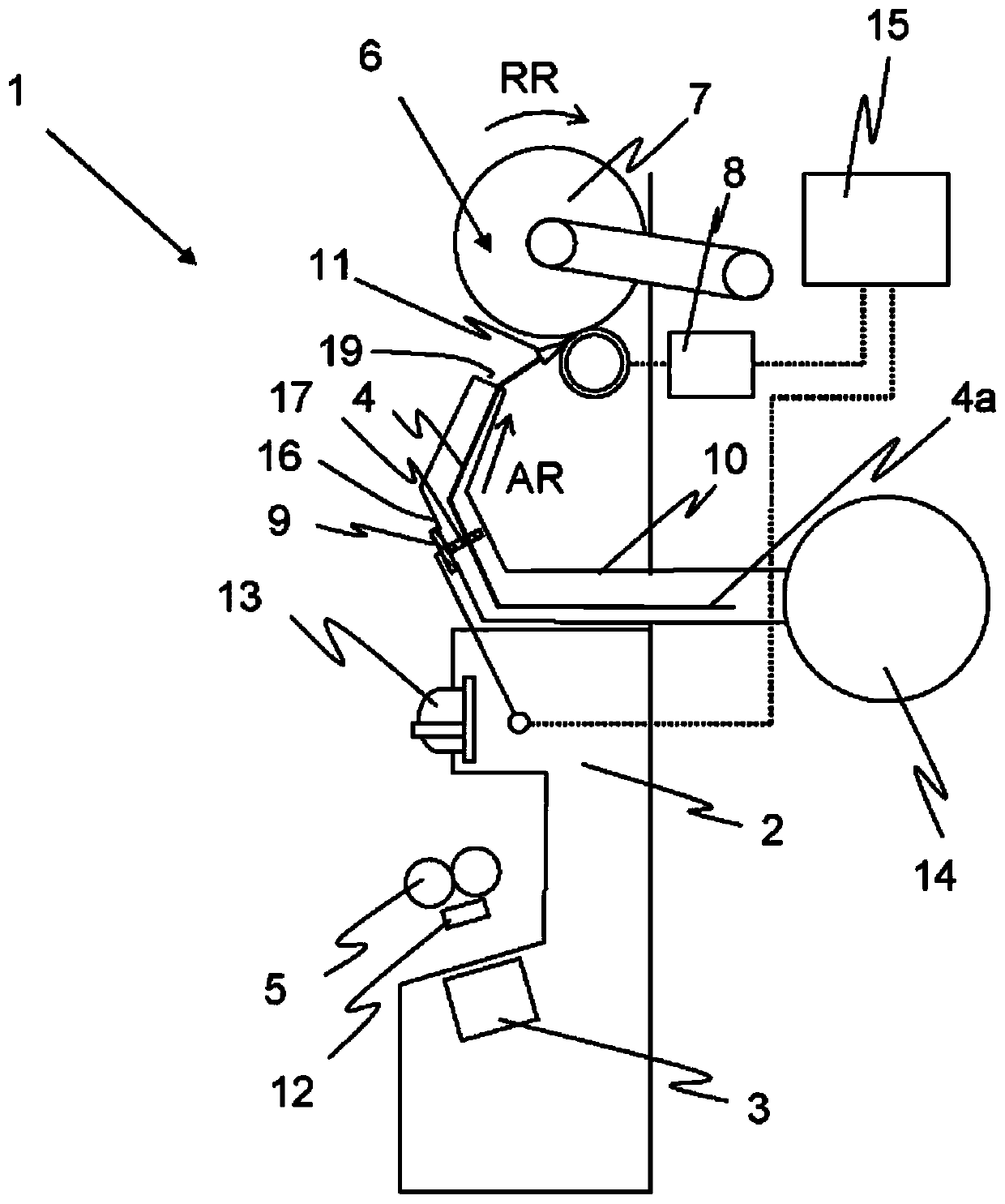

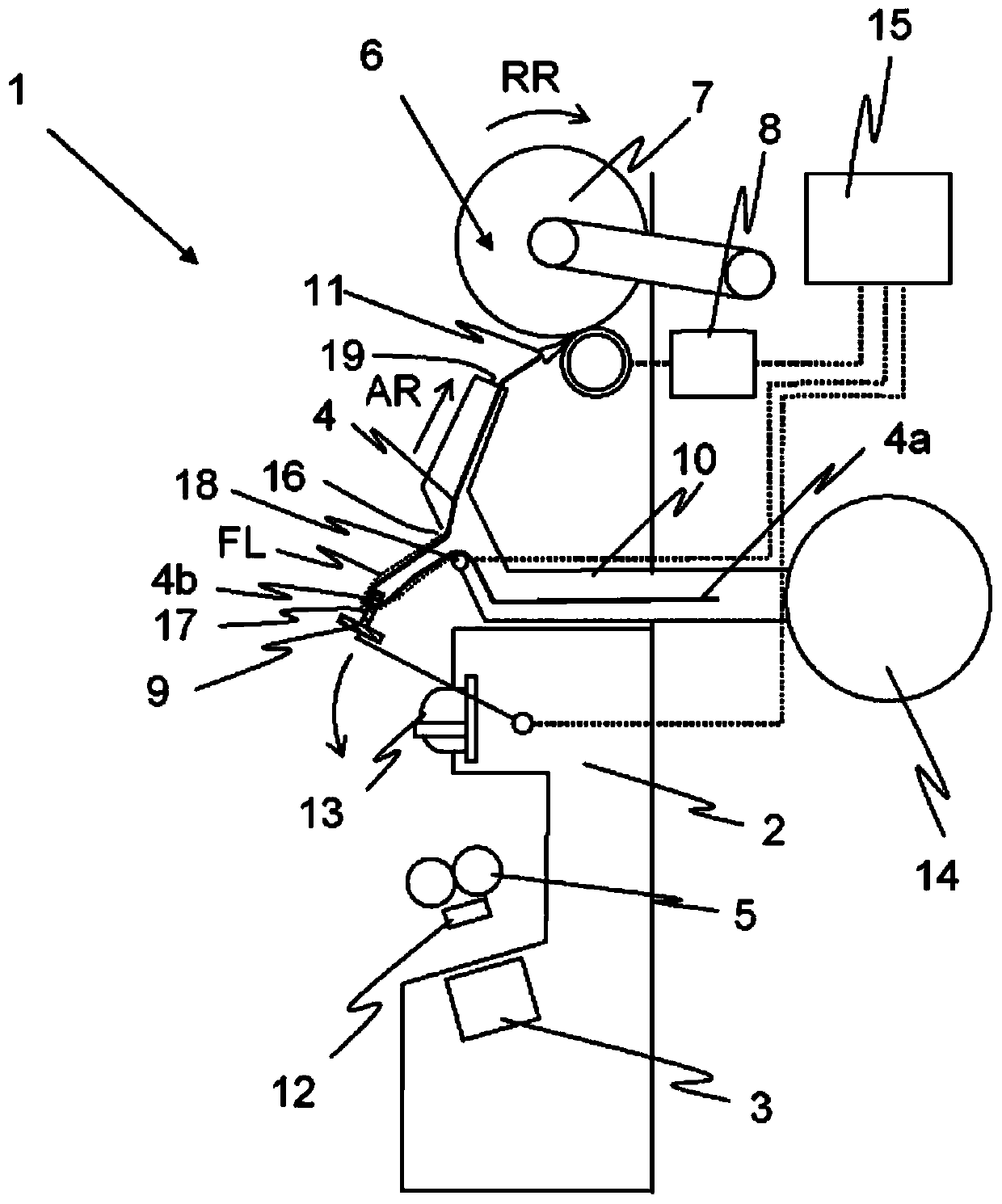

[0025] figure 1 Shown is a schematic sectional view of a station 2 of a textile machine 1 . Station 2 is equipped with spinning equipment 3 for producing yarn 4 in a conventional manner. The yarn drawing device is composed of two yarn drawing rollers 5, and the yarn 4 is extracted from the spinning device 3 through the yarn drawing device, and sent to the winding device 6, and the yarn is wound on the bobbin 7 through the yarn conveyor 11. For this purpose, the winding device 6 comprises a drive device 8, which, in the above-mentioned normal driving situation, pushes the bobbin in normal rotation in the normal direction of rotation DR (see arrow). Like the direction of rotation DR, the normal withdrawal direction AR of the yarn 4 is also marked with an arrow. The yarn 4 can also be connected to other devices between the draw-off roller 5 and the winding device 6, for example a waxing device 13 (Paraffiniereinrichtung) can be installed.

[0026] What was introduced above is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com