Gob-side entryretaining method for cutting off direct roof to make roadside supporting wall body

A technology of roadside support and empty roadway retention, which is applied in earthwork drilling, ground mining, underground mining, etc., can solve the problems of low construction efficiency and complex process of making roadside support walls, and achieve low cost of roadway formation and benefit The effect of roadway maintenance and improvement of roadway efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method of retaining a gob-side entry by cutting and directly topping it as the supporting wall beside the entry. The specific construction steps are as follows:

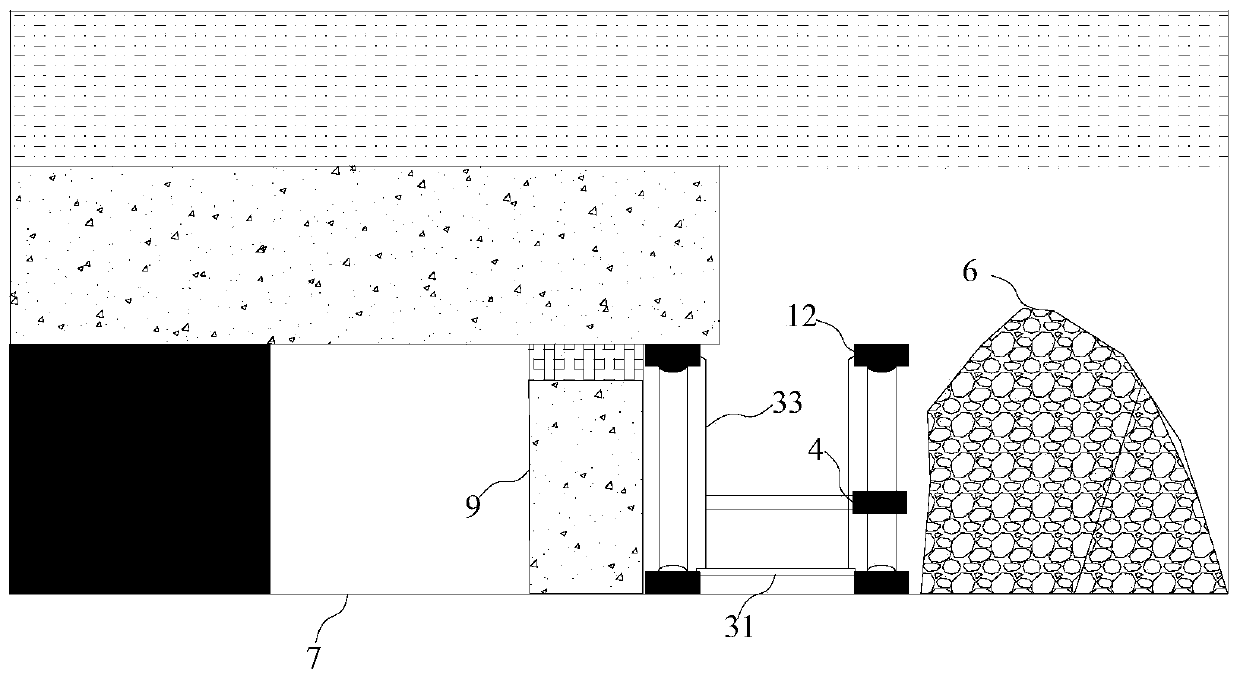

[0034] Step A. Install the gob-side entry support behind the end support of the working face, the end support 5 and the gob-side entry support are connected by a hydraulic cylinder 51, and the moving frame of the gob-side entry support is pushed by the hydraulic cylinder 51, Gobside retaining support includes supporting mechanism 1, drilling mechanism 2, descending mechanism 3 and pushing mechanism 4, such as Figure 4 shown.

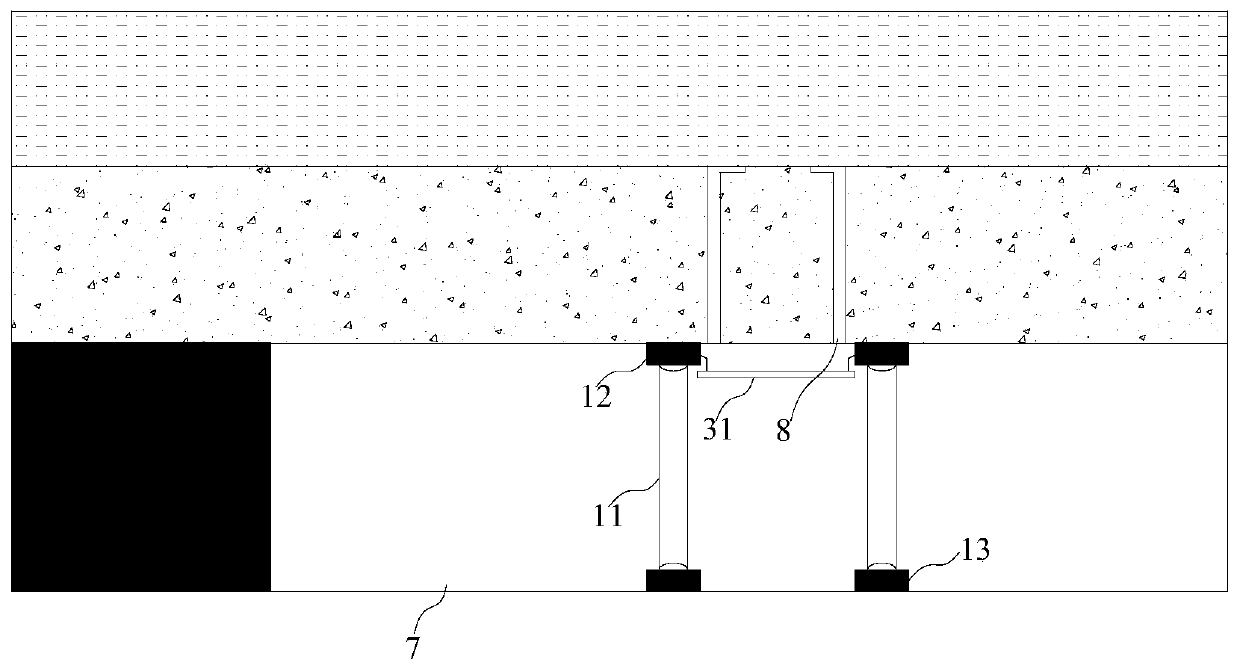

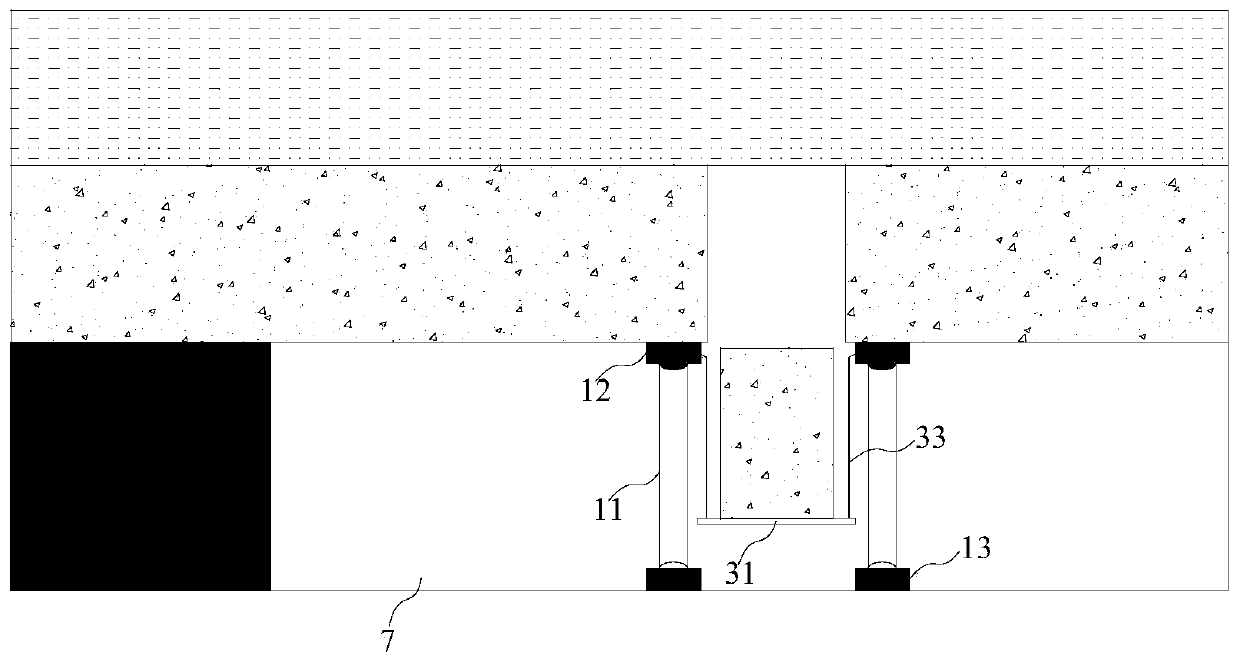

[0035] Among them, the support mechanism 1 of the gob-side entry retaining support includes a column 11, a top beam 12 and a bottom beam 13 to protect the construction space where the roof is cut off. The top beam 12 is connected to the upper end of the column, and the bottom beam 13 is connected to the lower end of the column 11. 1 is provided with four upright columns 11, which are...

Embodiment 2

[0051] In order to further illustrate the construction process of the gob-side entry retaining method of cutting off the direct roof as the roadside support wall, taking the 1310 working face of a certain mine as an example, the present invention will be further described in detail. The 1310 working face of this mine mainly mines 3 coal seams with a thickness of 2.8m. The roof stratum is fine sandstone, which belongs to the medium-hard roof. The mining roadway is excavated along the bottom, and the cross-sectional shape is rectangular. Mining is carried out by using the gob-side retaining method of cutting off the direct roof as the supporting wall beside the roadway. The construction steps include:

[0052] Step A. Install the gob-side entry support behind the end support of the working face. The end support and the gob-side entry support are connected by a hydraulic cylinder. The retaining support includes a supporting mechanism 1, a drilling mechanism 2, a lowering mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com