Two-step stoping and stope filling system and filling method of thick and large ore body in vertical direction

A vertical, thick and large ore body technology, applied in filling, earthwork drilling, surface mining, etc., can solve the problems of limited flow distance, accumulation slope, and poor stope roofing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

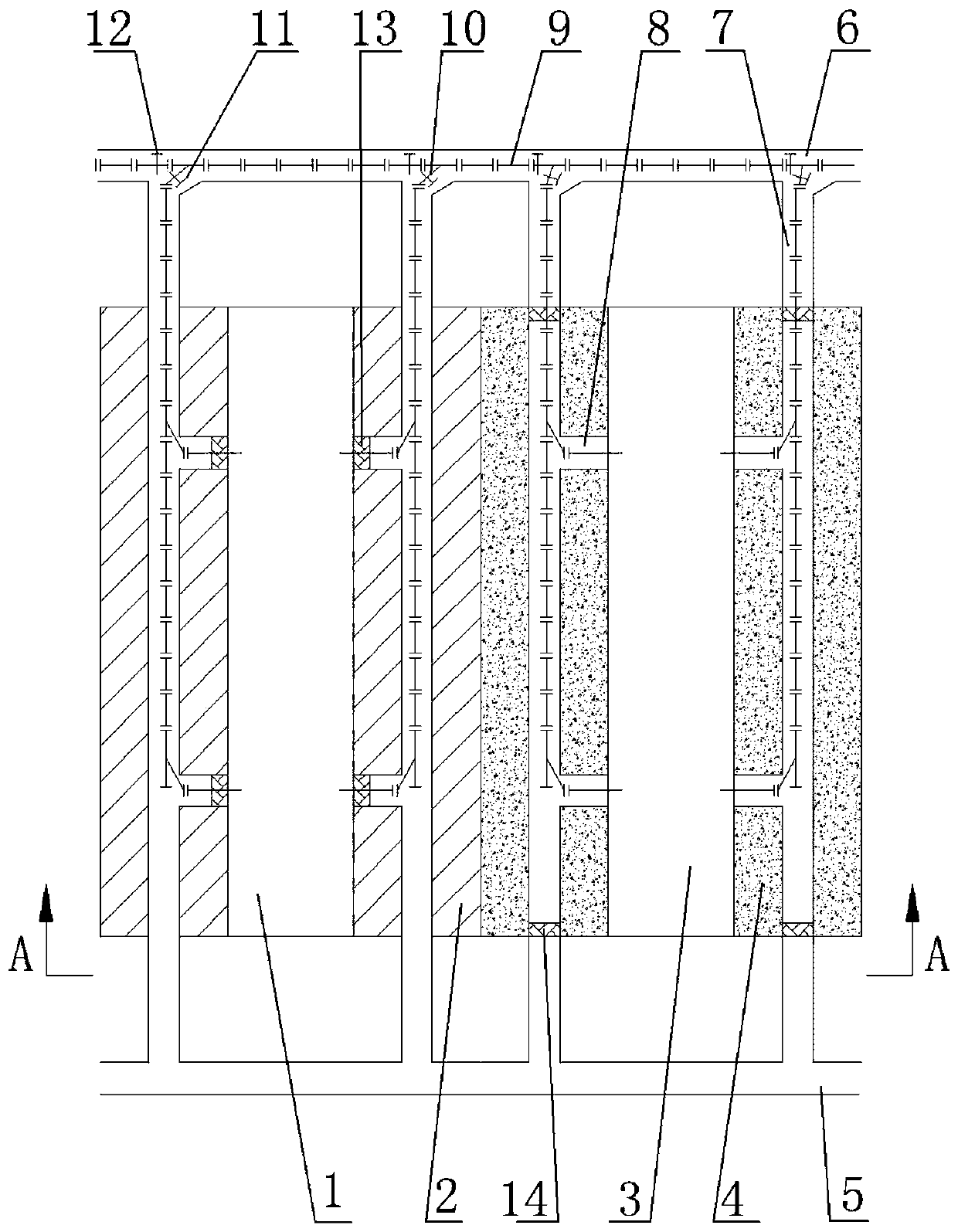

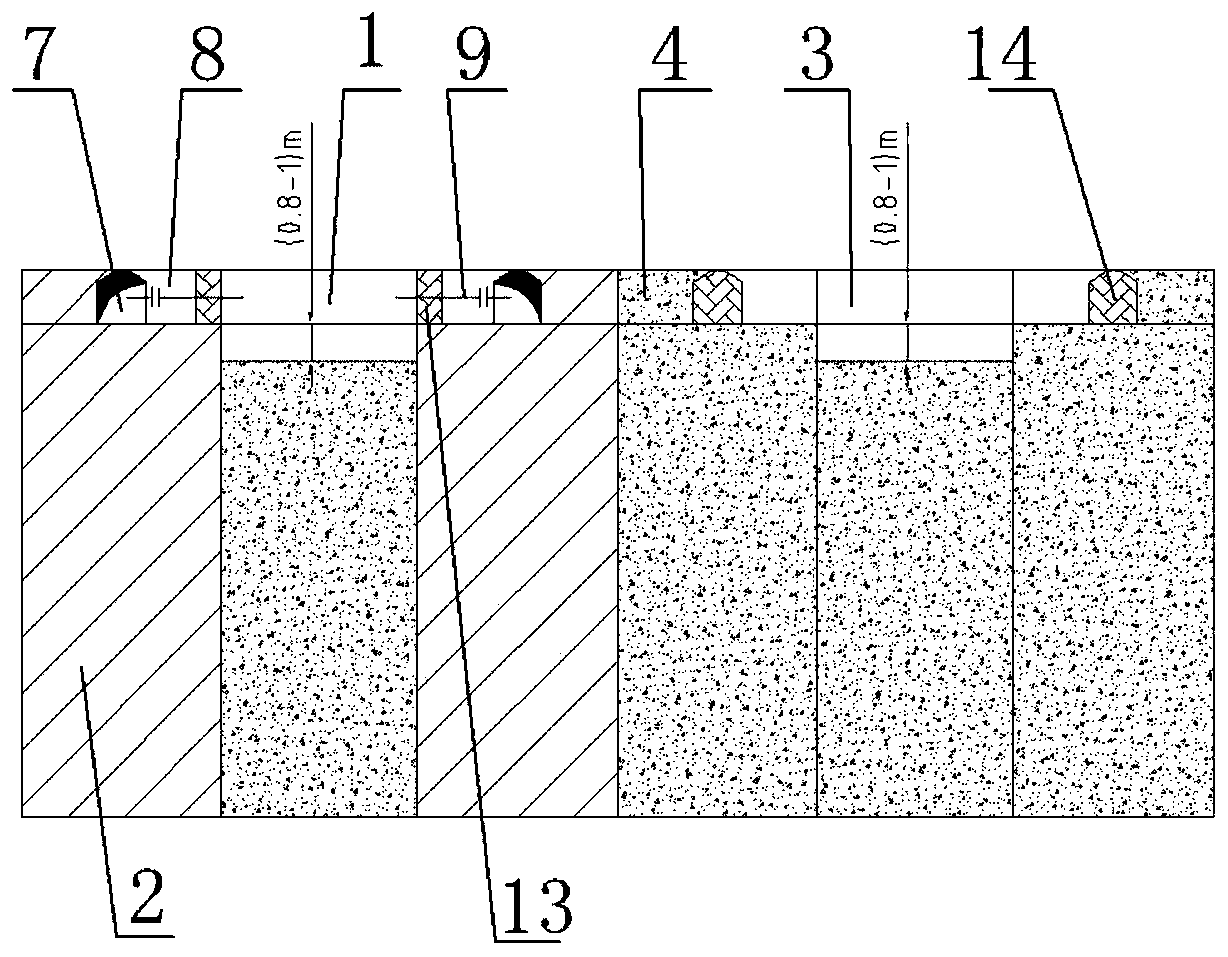

[0031] from figure 1 with figure 2 It can be seen that the stope filling system of the thick ore body in the present invention is two-step stope filling along the vertical direction, including filling veins 7, filling connecting roads 8, filling pipelines 9, gate valves 11, and one-step stope filling retaining walls 13 and the second step stope filling retaining wall 14, the stope includes a first step stope 1 and a second step stope 3 arranged vertically to the direction of the ore body, the two sides of the first step stope 1 are the ore body 2, and the two sides of the second step stope 3 It is the filling body 4 that has been cured, the footwall transportation roadway 5 is in the surrounding rock of the stope footwall, and the hanging wall filling roadway 6 is in the surrounding rock of the stope wall.

[0032] Filling veins 7 are arranged in each ore body 2 and filling body 4, the upper end of filling veins 7 is connected to the filling roadway 6 in the hanging wall, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com