Steering oil tank and machining process thereof

A processing technology and oil tank technology, applied in the direction of fluid steering mechanism, oil supply tank device, fluid pressure actuating device, etc., can solve the problems of hydraulic oil splashing, affecting the working performance of steering oil tank, etc., to ensure the stability of the effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

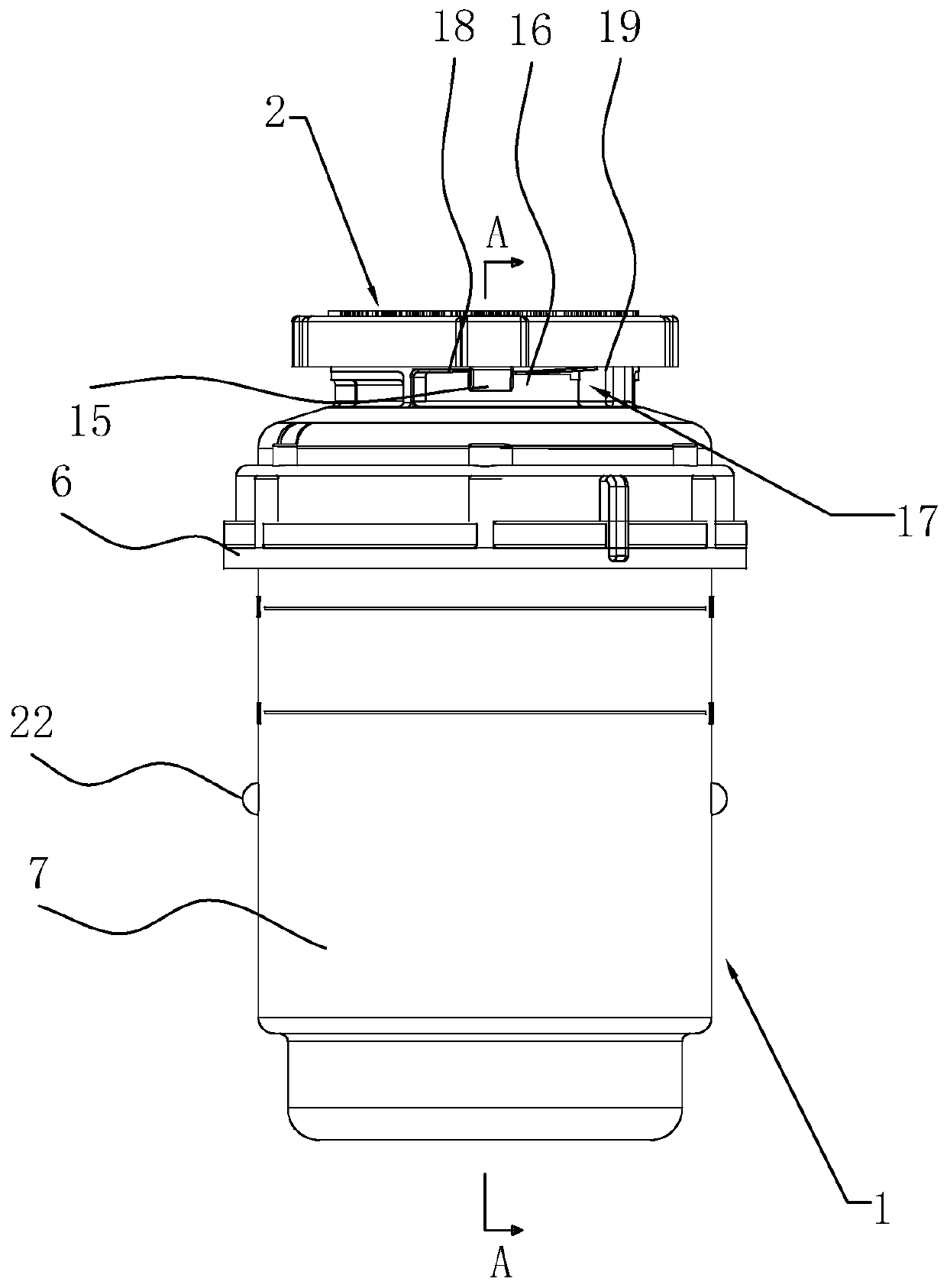

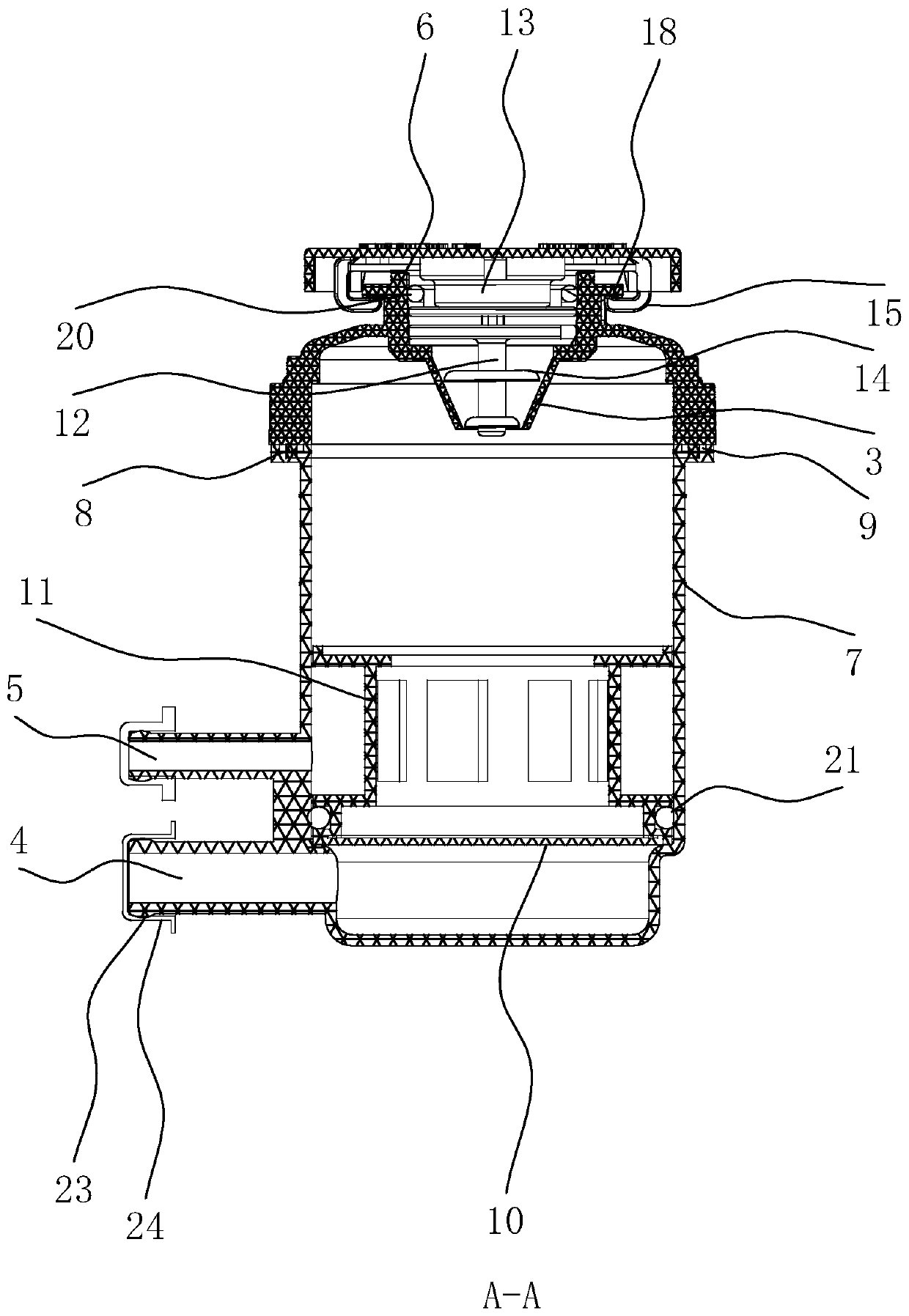

[0044] refer to figure 1 and figure 2 , is a steering oil tank disclosed by the present invention, comprising a tank body 1 and a tank cover 2, the tank body 1 is provided with an oil tank mouth 3, an oil inlet 4 and an oil outlet 5, and the engine oil is added through the oil tank mouth 3 Into the tank 1, the engine oil in the tank 1 provides power to the truck through the oil outlet 5, and the engine oil flows back into the tank 1 through the oil inlet 4. When the engine oil works in the tank 1 for a long time, it will vibrate and generate heat. The engine oil will flow out from the connection between the tank body 1 and the tank cover 2, which will affect the normal power supply effect of the steering oil tank to the truck. In order to ensure the sealing effect between the tank body 1 and the tank cover 2, the tank body 1 includes the upper tank body 6 and the lower tank body 7. The can lid 2 includes an abutment portion and a protective portion 13, and the abutment porti...

Embodiment 2

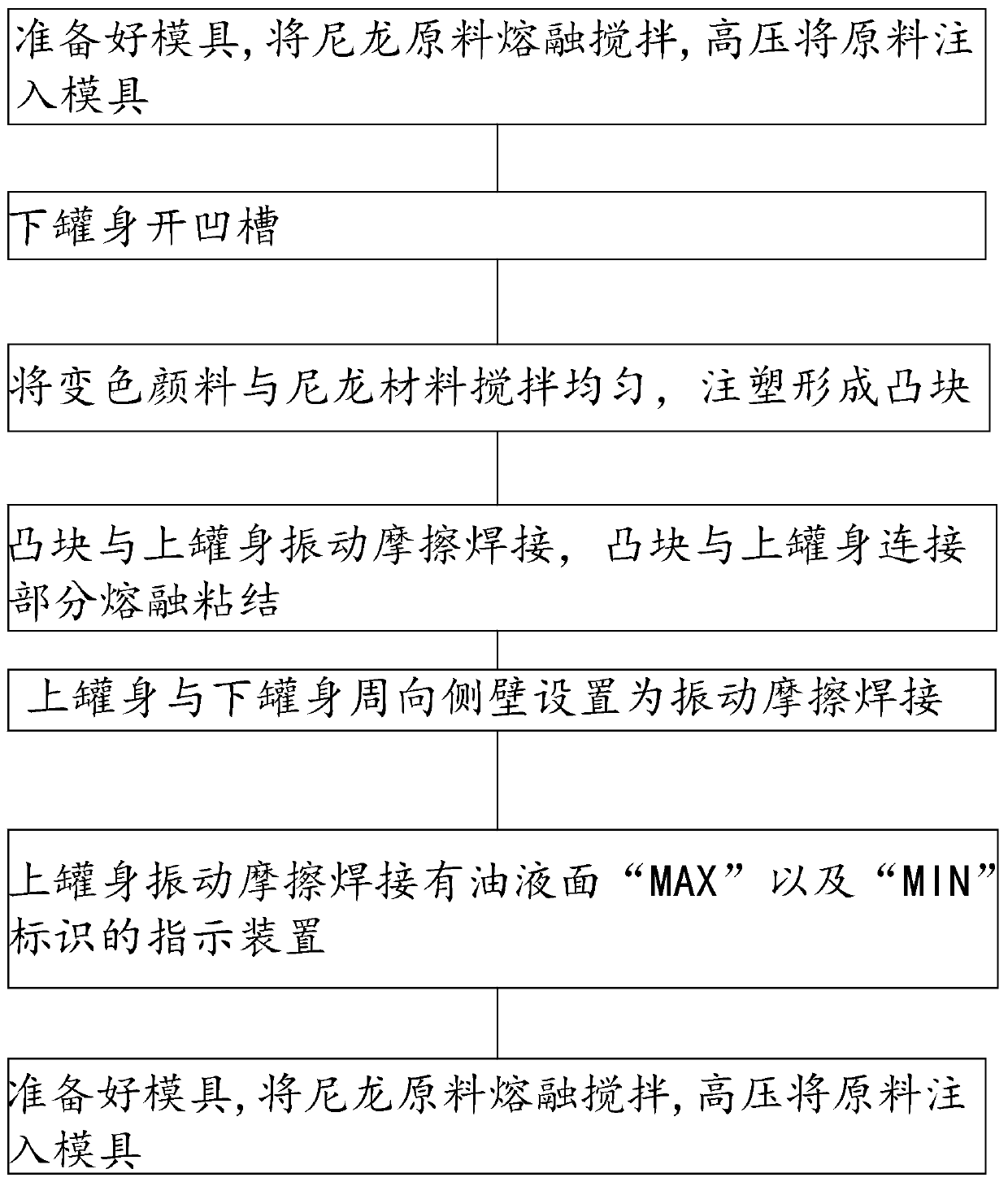

[0050] refer to figure 1 and image 3 , a kind of processing technology that turns to oil tank, comprises the steps:

[0051] Step 1: Prepare the mold, melt and stir the nylon raw material, and inject the raw material into the model under high pressure;

[0052] Step 2, groove the lower tank body (9);

[0053] Step 3, mix the color-changing pigment and nylon material evenly, and inject to form bumps (8),

[0054] Step 4, the bump (8) and the upper tank body (6) are vibration-friction welded, and the connection part between the bump (8) and the upper tank body (6) is fused and bonded;

[0055] Step five, setting the circumferential side walls of the upper tank body (6) and the lower tank body (7) as vibration friction welding;

[0056] Step 6, the upper tank body (6) is vibrated and friction-welded with the indicating device marked with the oil level "MAX" and "MIN";

[0057] Step seven, ultrasonic welding is carried out between the protective part (13) and the abutment pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com