Float glass width real-time detection device

A float glass and detection device technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problem that the width and pulling amount of the glass plate cannot be reflected in time, the measurement data cannot objectively reflect the glass plate in time, and the stability of glass production is unfavorable Factors and other issues, to achieve the effect of reducing anti-interference ability, improving reliability and accuracy, and measuring quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below with reference to the accompanying drawings.

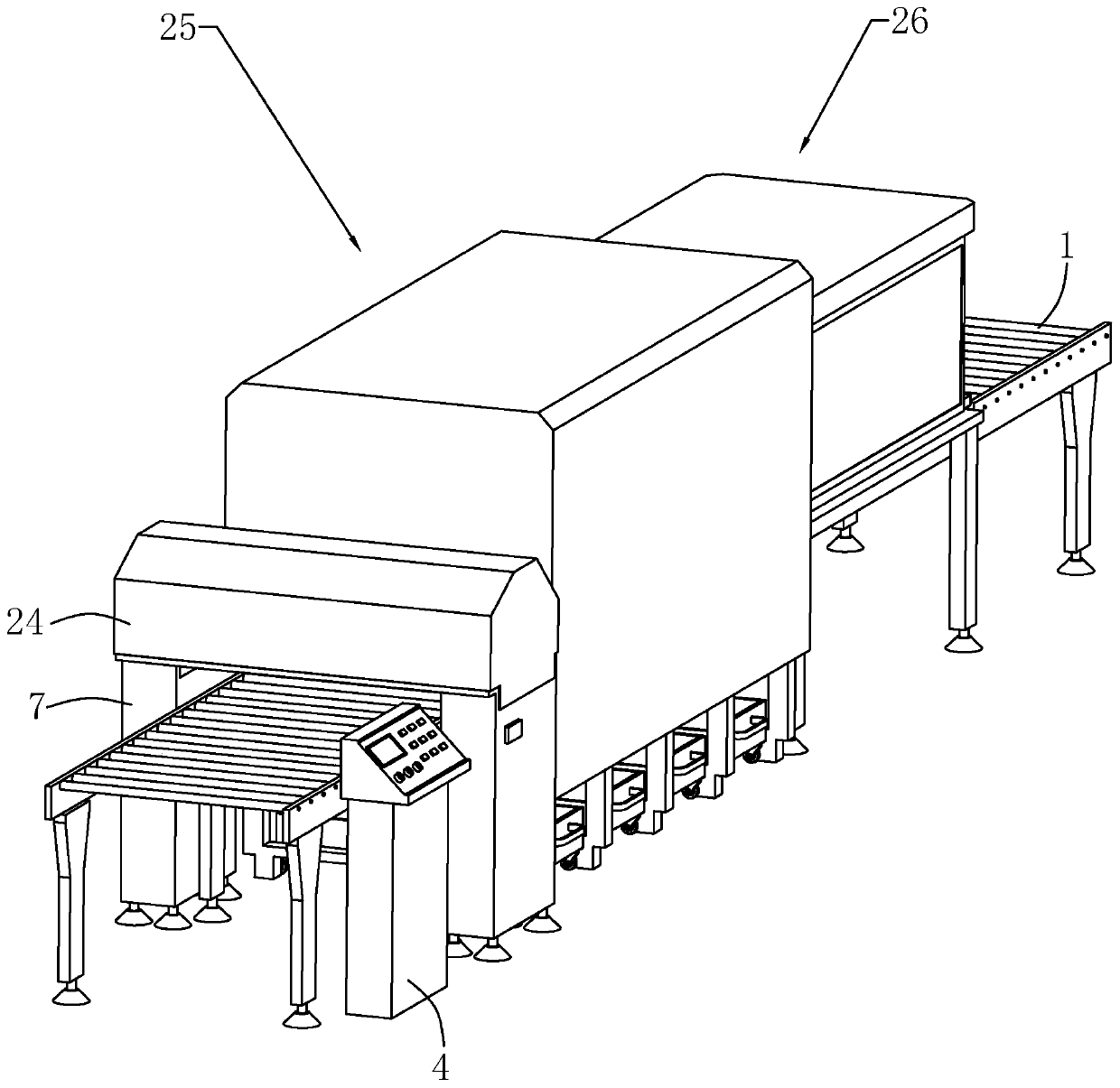

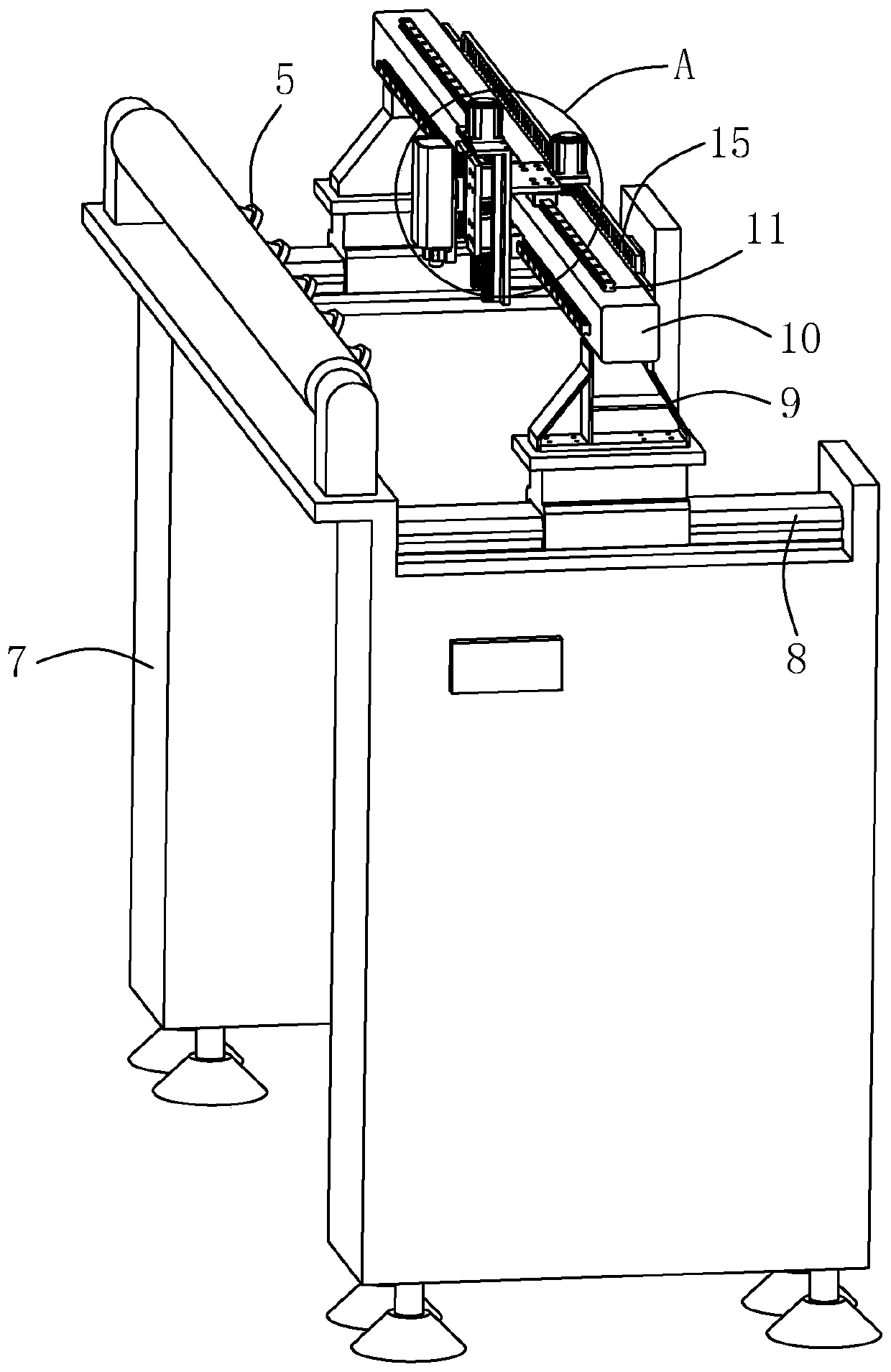

[0023] A real-time detection device for the width of float glass, such as figure 1 and figure 2 As shown, it includes a testing platform 1 for placing the glass to be tested and capable of driving the glass to be tested to move on it. The glass to be tested is preheated, heated and cooled sequentially on the testing platform 1 . There are two support bases 7 , and they are respectively located on both sides of the detection platform 1 ; the light source assembly and the high-speed camera 6 are installed across the two support bases 7 .

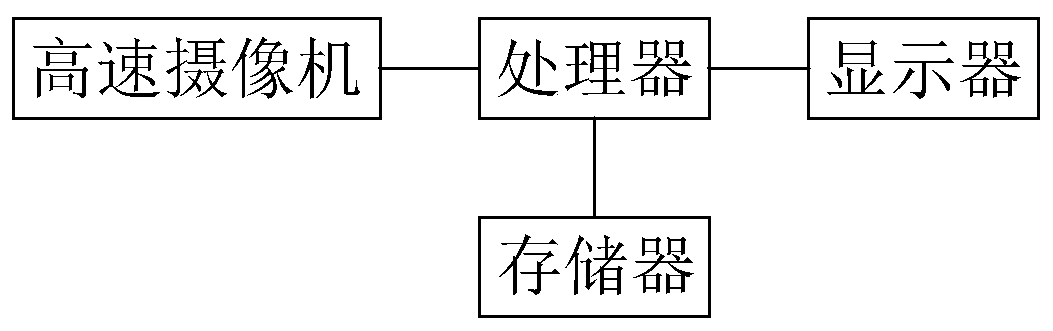

[0024] The light source assembly includes a number of light lamps 5 arranged in strips. The light lamps 5 at both ends are inclined toward the middle to illuminate the sides of the glass to be inspected. The light source assembly illuminates the upper surface and both sides of the glass to be inspected, so that the entire T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com