A device and preparation method for producing combustible gas by pyrolyzing carbon black from tires

A tire pyrolysis and carbon black technology, applied in the manufacture of combustible gas, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of low commercial value, poor surface activity, practical application limitations, etc., to improve the use value , The effect of low equipment investment cost and compact equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

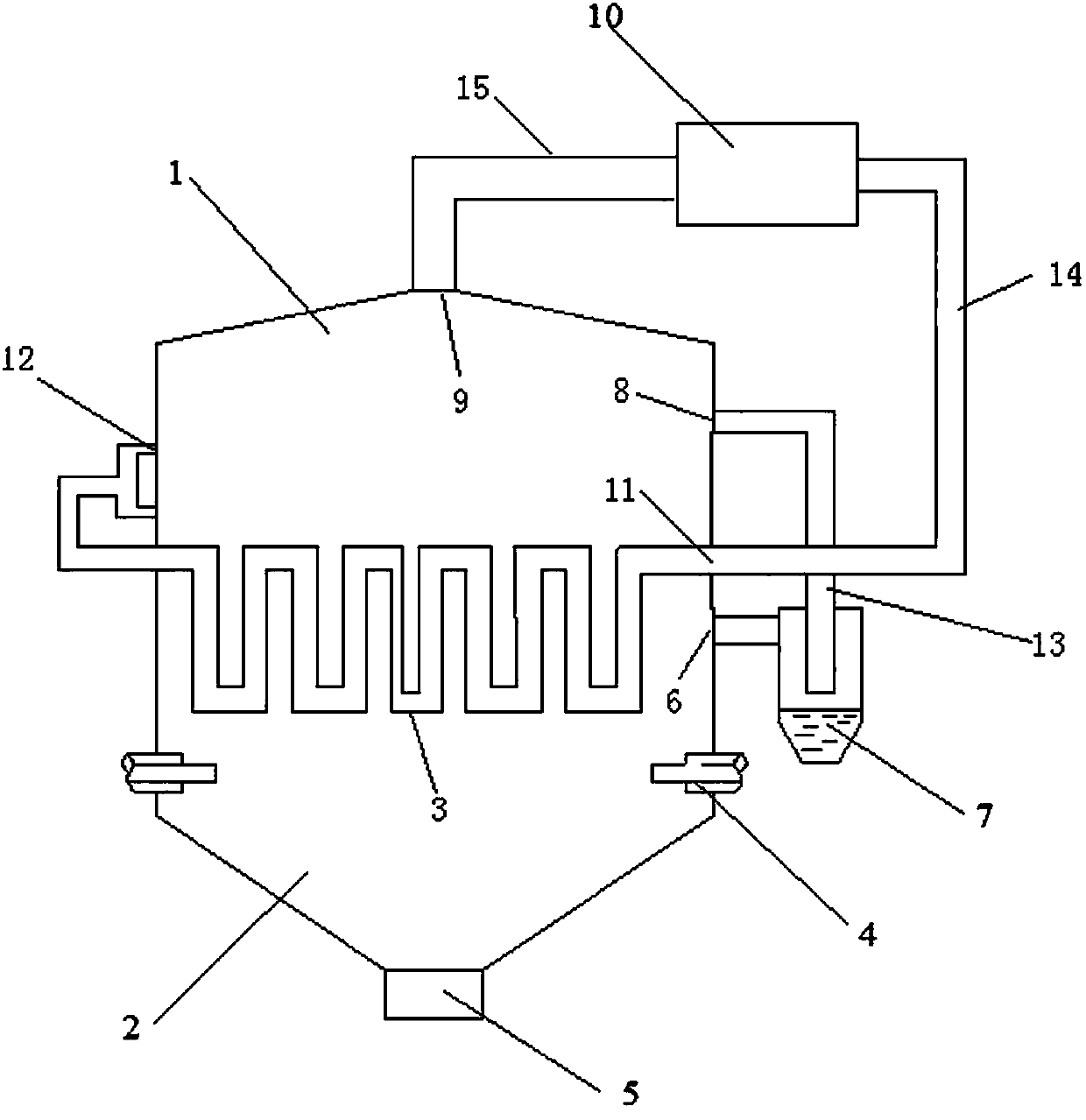

Image

Examples

Embodiment 1

[0031] Utilize the device of the present invention to carry out the method for producing combustible gas by tire pyrolysis carbon black, comprising the following steps:

[0032] (1) In the combustion chamber, carbon black undergoes incomplete combustion reaction with excess air, the excess air coefficient is 0.6, and the combustion temperature of carbon black is 800°C, generating high-temperature flue gas containing carbon dioxide;

[0033] (2) The high-temperature flue gas enters the gasification chamber after passing through the gas-solid separation device and absorbing and removing part of the carbon dioxide, and the CO in the flue gas 2 The concentration is 33%, the temperature in the gasification chamber is 700°C, the particle size range of carbon black in the gasification chamber is 40-50 μm, and the gasification reaction occurs with carbon dioxide and water vapor in the high-temperature flue gas, and the water vapor and water vapor in the gasification chamber are control...

Embodiment 2

[0037] Utilize the device of the present invention to carry out the method for producing combustible gas by tire pyrolysis carbon black, comprising the following steps:

[0038] (1) In the combustion chamber, carbon black undergoes incomplete combustion reaction with excess air, the excess air coefficient is 0.7, and the combustion temperature of carbon black is 1000°C, generating high-temperature flue gas containing carbon dioxide;

[0039] (2) The high-temperature flue gas enters the gasification chamber after passing through the gas-solid separation device and absorbing and removing part of the carbon dioxide, and the CO in the flue gas 2The concentration is 36%, the temperature in the gasification chamber is 800°C, the particle size of carbon black in the gasification chamber is 20-40 μm, and it reacts with carbon dioxide and water vapor in the high-temperature flue gas, and the water vapor and water vapor in the gasification chamber are controlled. The equivalent ratio of...

Embodiment 3

[0043] Utilize the device of the present invention to carry out the method for producing combustible gas by tire pyrolysis carbon black, comprising the following steps:

[0044] (1) In the combustion chamber, carbon black undergoes incomplete combustion reaction with excess air, the excess air coefficient is 0.8, and the combustion temperature of carbon black is 1100°C, generating high-temperature flue gas containing carbon dioxide;

[0045] (2) The high-temperature flue gas enters the gasification chamber after passing through the gas-solid separation device and absorbing and removing part of the carbon dioxide, and the CO in the flue gas 2 The concentration is 40%, the temperature in the gasification chamber is 900°C, the particle size of carbon black in the gasification chamber is controlled below 20 μm, the carbon dioxide and water vapor in the high-temperature flue gas undergo gasification reaction, and the water vapor and carbon black in the gasification chamber are contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com