Torsional shear force measurement device for adhesion strength between material surfaces and icing layer

A technology of adhesion strength and measuring device, which is applied in the direction of measuring device, using stable shear force to test material strength, analyzing materials, etc., can solve the problems of dangerous use, high speed of measuring device, difficult operation, etc., to achieve The effect of simple and convenient operation, low manufacturing cost and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

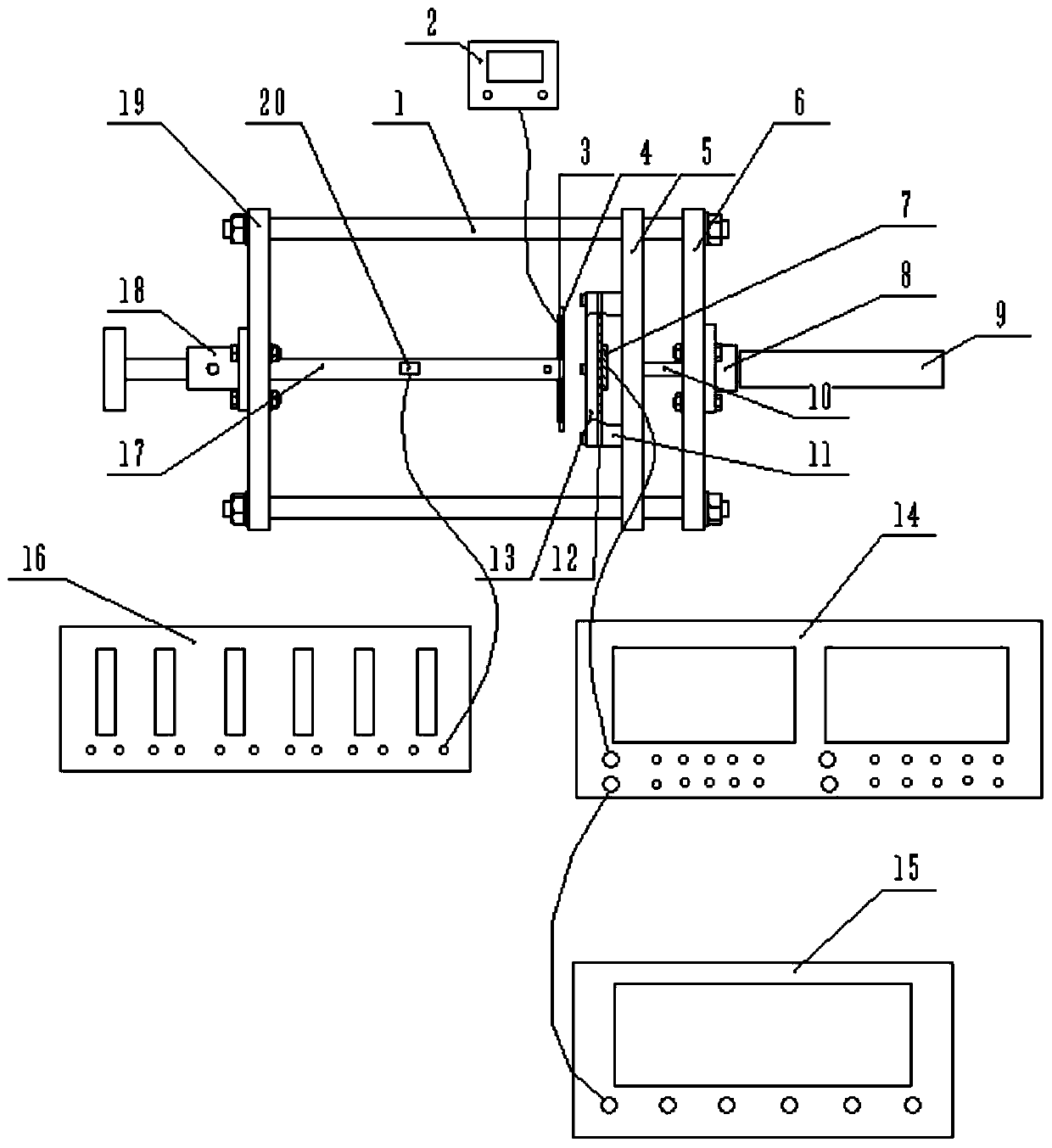

[0009] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A device for measuring torsional shear force of material surface and ice layer adhesion strength includes micrometer head 9, temperature controller 2, power amplifier 14, signal generator 15 and strain gauge 16, on four axes arranged parallel to each other The left flat plate 19 and the right flat plate 6 are respectively fixed on the ends of the two sides of the rod 1, and the torque shaft 17 is rotatably supported by the support sleeve 18 on the left flat plate 19, and the aluminum plate 4 is installed on the right end of the torque shaft 17. , the right end surface of the aluminum plate 4 is pitted, the heating plate 3 is assembled on the left end surface of the aluminum plate 4, the rosette 20 is attached to the torque shaft 17, and the wire connects the temperature controller 2 with the heating plate 3 and the strain gauge 16 It communicates with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com