High-sensitivity microwave humidity sensor based on two-dimensional strip-shaped MoO3 nanometer materials

A humidity sensor and nano-material technology, applied in the direction of using microwaves to test moisture content, can solve the problems of low sensitivity and long response time, and achieve high operating frequency, effective humidity detection, and reliable results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

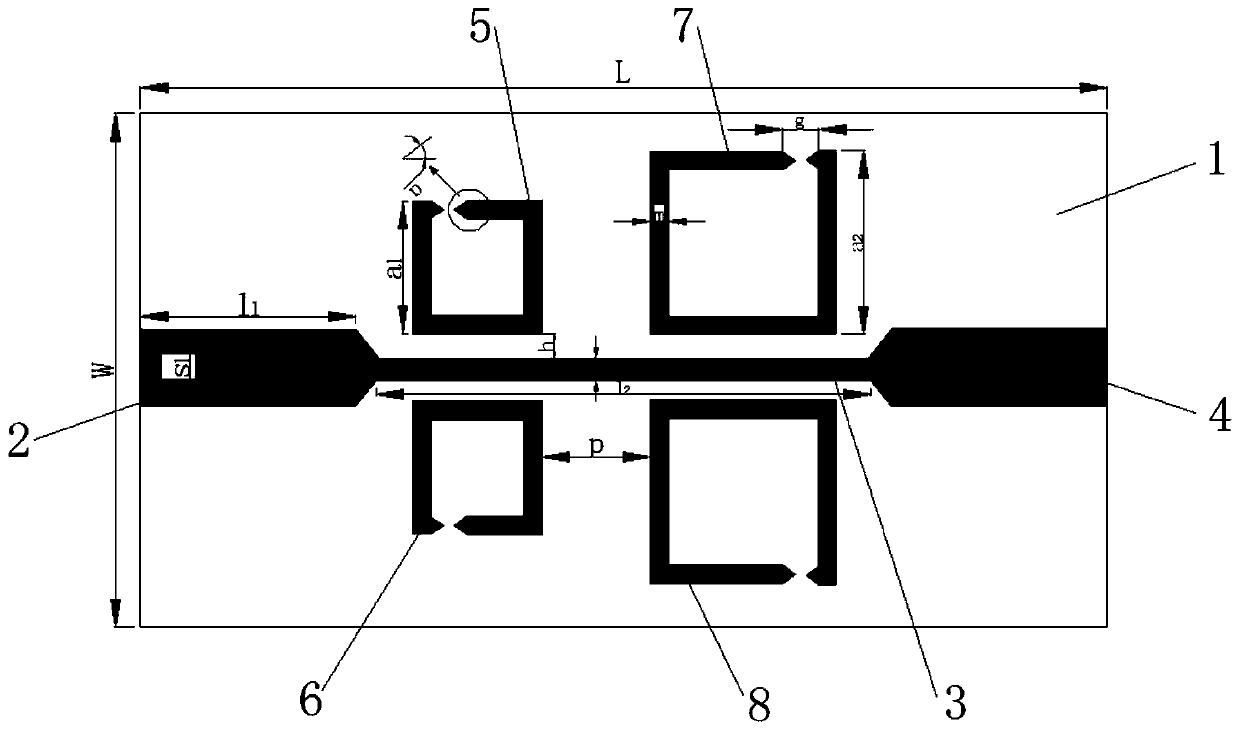

[0019]Specific implementation mode 1: This implementation mode is based on two-dimensional banded MoO 3 The high-sensitivity microwave humidity sensor of nanomaterials includes a substrate 1, a first port feeder 2, a connecting microstrip line 3, a second port feeder 4, four rectangular ring open-loop resonators and sensitive materials, a first port feeder 2, a connecting microstrip The strip line 3, the second port feeder line 4 and the four rectangular open-loop resonators are all printed on the surface of the substrate 1 using printed circuit board technology, connecting the microstrip line 3 to form a straight line segment, and connecting one end of the microstrip line 3 to the first The port feeder 2 is connected, and the other end connected to the microstrip line 3 is connected to the second port feeder 4;

[0020] Among them, the structures of No. 1 rectangular ring split-ring resonator 5 and No. 2 rectangular ring split-ring resonator 6 are the same, and the structures...

specific Embodiment approach 2

[0022] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the shape of the loop of the rectangular ring open-loop resonator is a square.

specific Embodiment approach 3

[0023] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that the opening of the rectangular ring split-ring resonator has a sharp-angled structure.

[0024] The opening of the resonator in this embodiment is a sharp-angled structure with two open ends facing each other.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Line width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com