A vortex type cable cooling device

A cooling device and cable technology, applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve problems such as poor cooling effect, achieve the effect of increasing cooling effect, lengthening path, and reducing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is further elaborated in detail in conjunction with the accompanying drawings and specific embodiments:

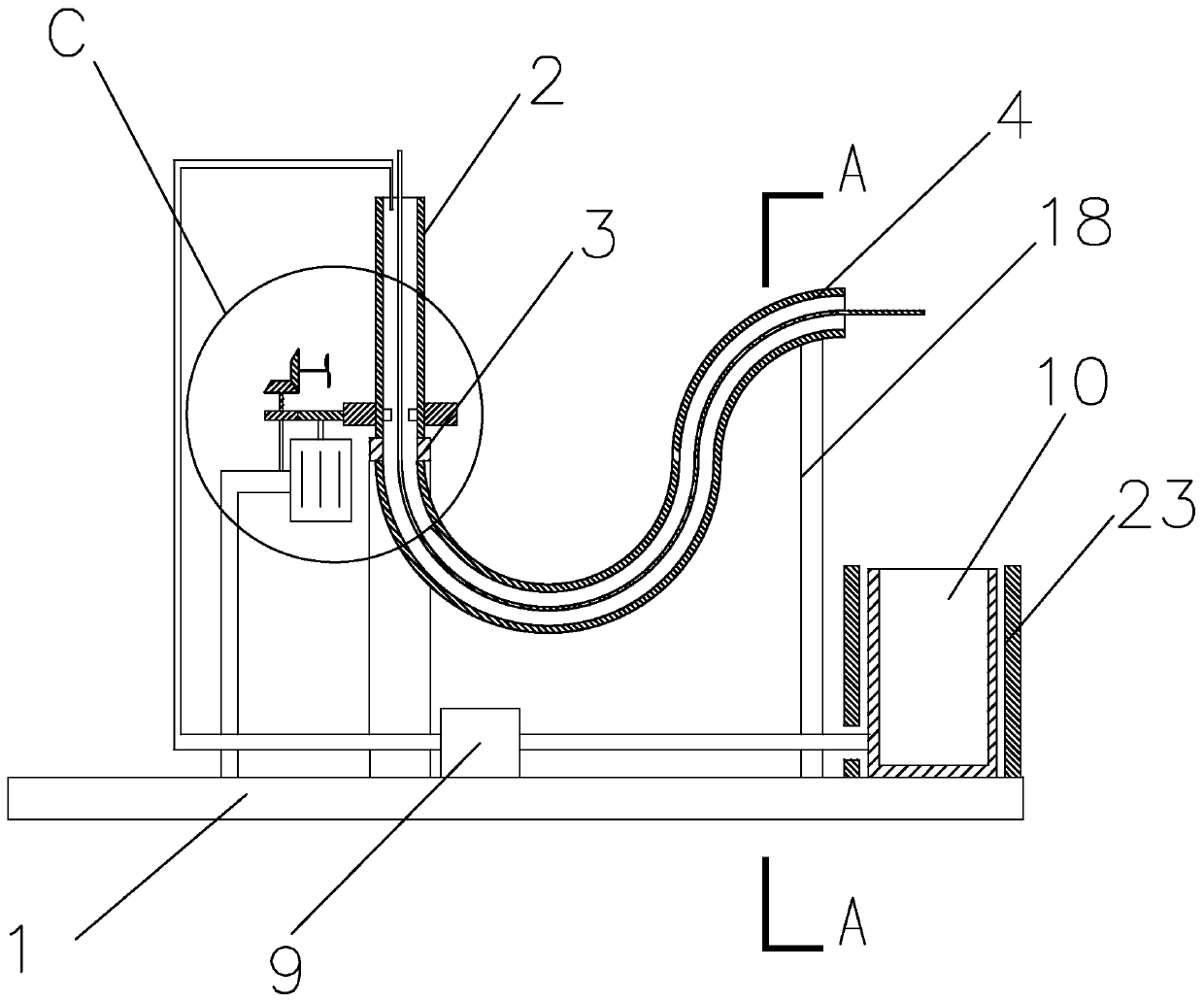

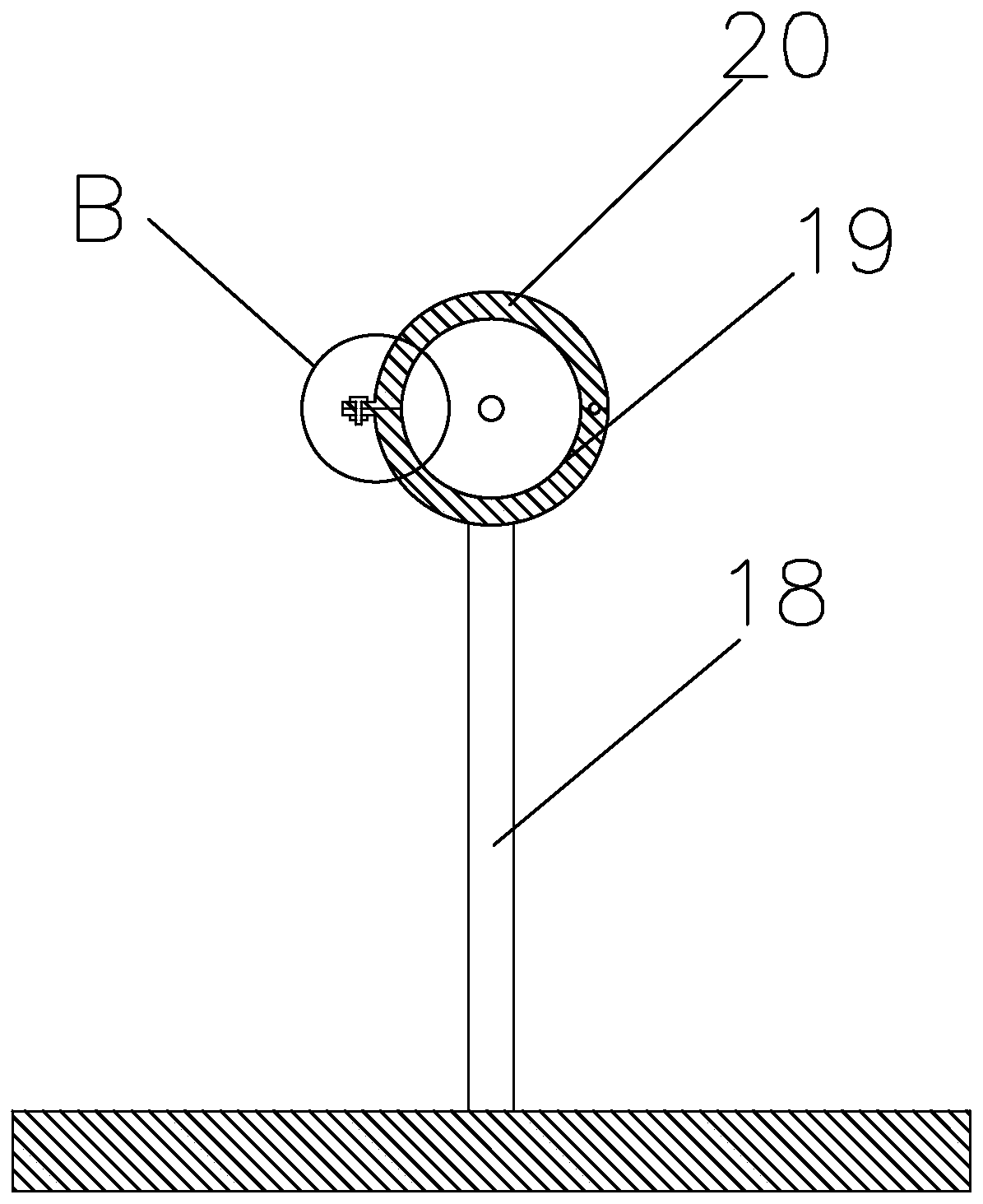

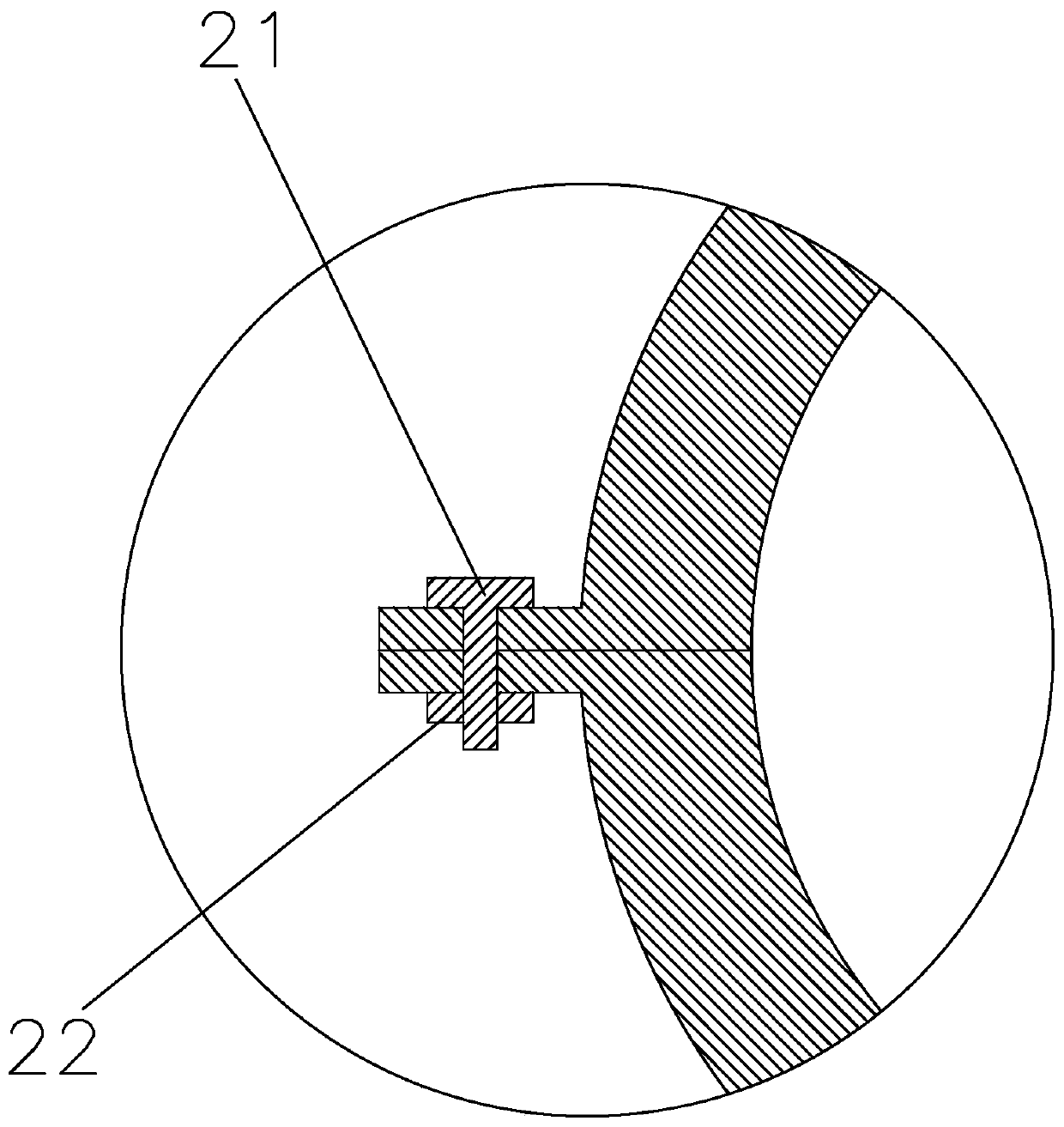

[0019] figure 1 and Figure 4 It is a vortex-type cable cooling device, including a base 1, on which a vertical rotating tube 2, an adapter sleeve 3 and a corrugated tube 4 are arranged, and the bottom end of the rotating tube 2 is connected through an adapter The sleeve 3 is connected to one end of the bellows 4, the adapter sleeve 3 is rotationally connected to the rotating pipe 2, the adapter sleeve 3 is fixedly connected to the bellows 4, the base 1 is provided with a pillar 18, and the bottom of the pillar 18 The end of the bellows 4 is fixed on the base 1, and the end of the bellows 4 away from the adapter sleeve 3 is connected to the top of the pillar 18, and the level of the end of the bellows 4 away from the adapter sleeve 3 is lower than that of the top of the rotating tube 2. , the adapter sleeve 3 is affixed to the base 1, a numbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com