PTC electric heating device used on dust hopper of electric dust remover

A technology of electric heating device and electrostatic precipitator, applied in the direction of electric heating device, ohmic resistance heating parts, electrical components, etc. In order to avoid problems such as high strength, the effect of avoiding system inoperability, simple and reliable temperature control, and reducing the incidence of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

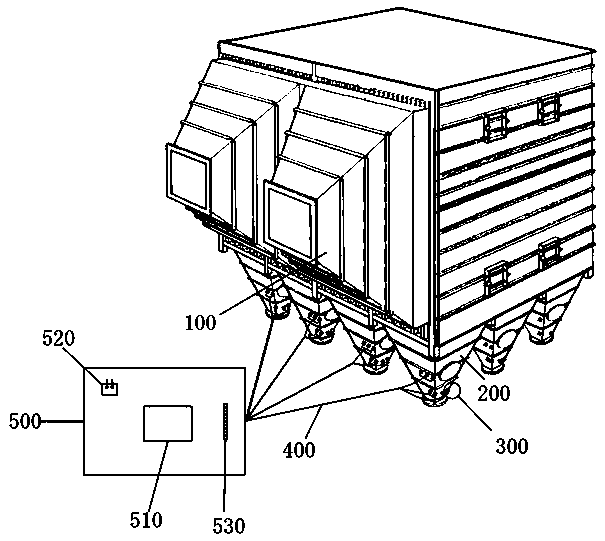

[0023] Such as figure 1 , a PTC electric heating device for an ash hopper of an electrostatic precipitator, comprising a plurality of PTC heating elements 310 arranged on the outer wall of an ash hopper 200 and a controller 510 .

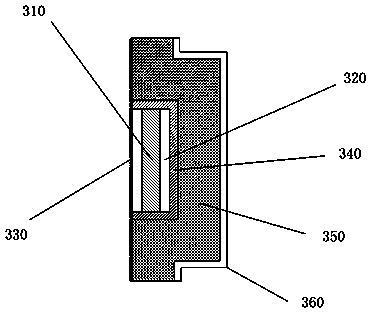

[0024] Such as figure 2 Each of the PTC heating elements 310 is fixed on the outer wall of the ash hopper 200 by a heat-resistant heat-conducting glue 330 , and the heat-conducting glue 330 is made of silicone glue to tightly glue the PTC heating element 310 and the outer wall of the ash hopper 200 together.

[0025] The outer side of each of the PTC heating elements 310 is provided with a protective shell. The protective shell includes an insulating layer 340 , a thermal insulation material layer 350 and a protective layer 360 wrapped on the non-heating surface of the PTC heating element 310 in sequence. The surface of the PTC heating element 310 is equipped with an insulating layer 340, which is made of polyimide film, which is used for electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com