Blade superposed type paddy field ridger achieving vibratory compaction

A technology for vibration compaction and ridge building, which is applied in agricultural machinery and implements, shovels, plows, etc., can solve the problems of unsuitable farming mode, inconvenient crop cultivation, and high labor intensity, so as to ensure rice production and speed up operation efficiency. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the accompanying drawings.

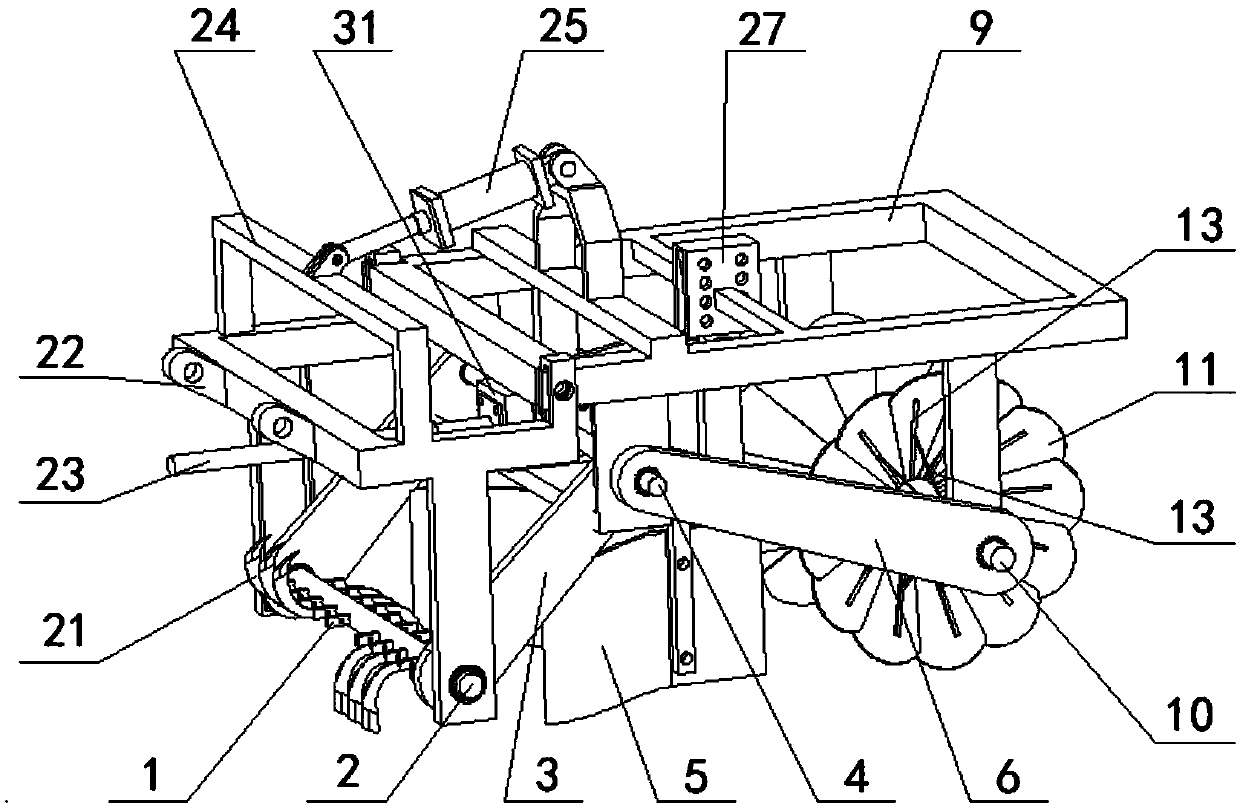

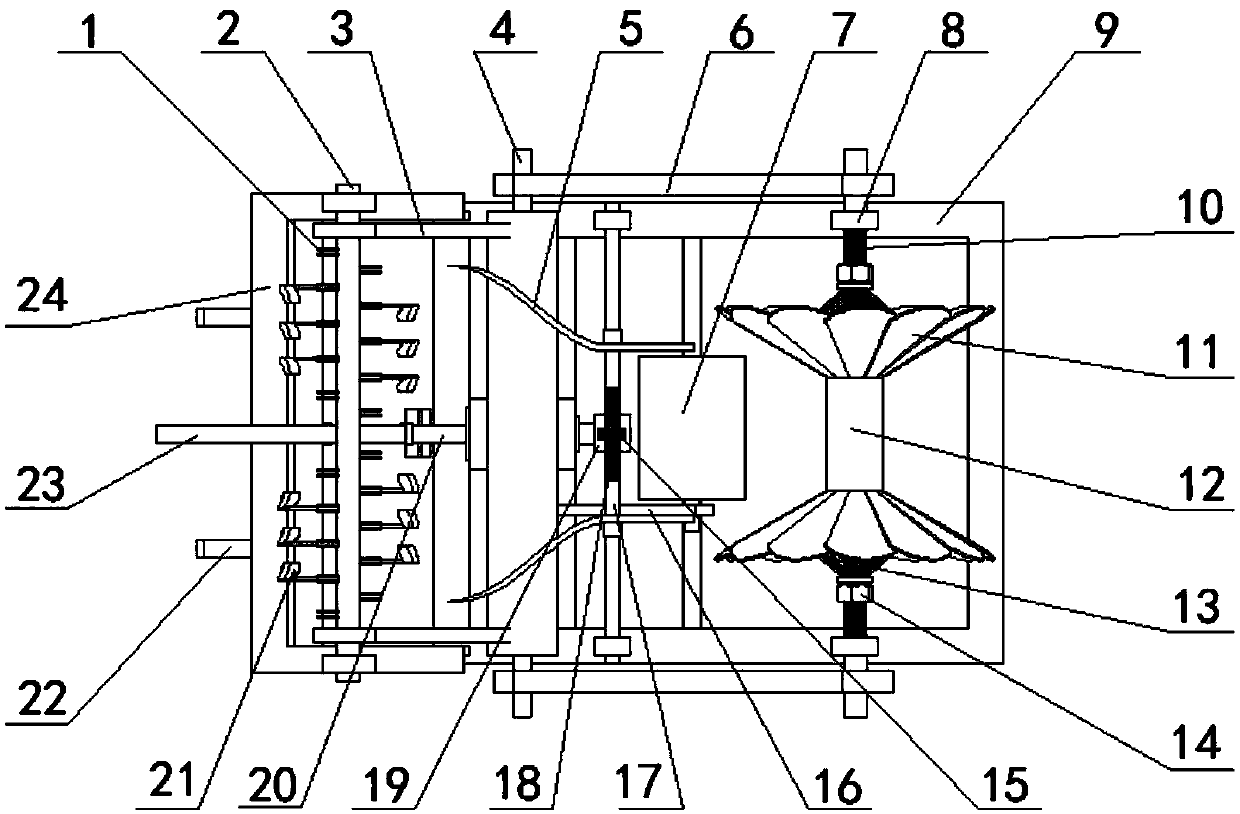

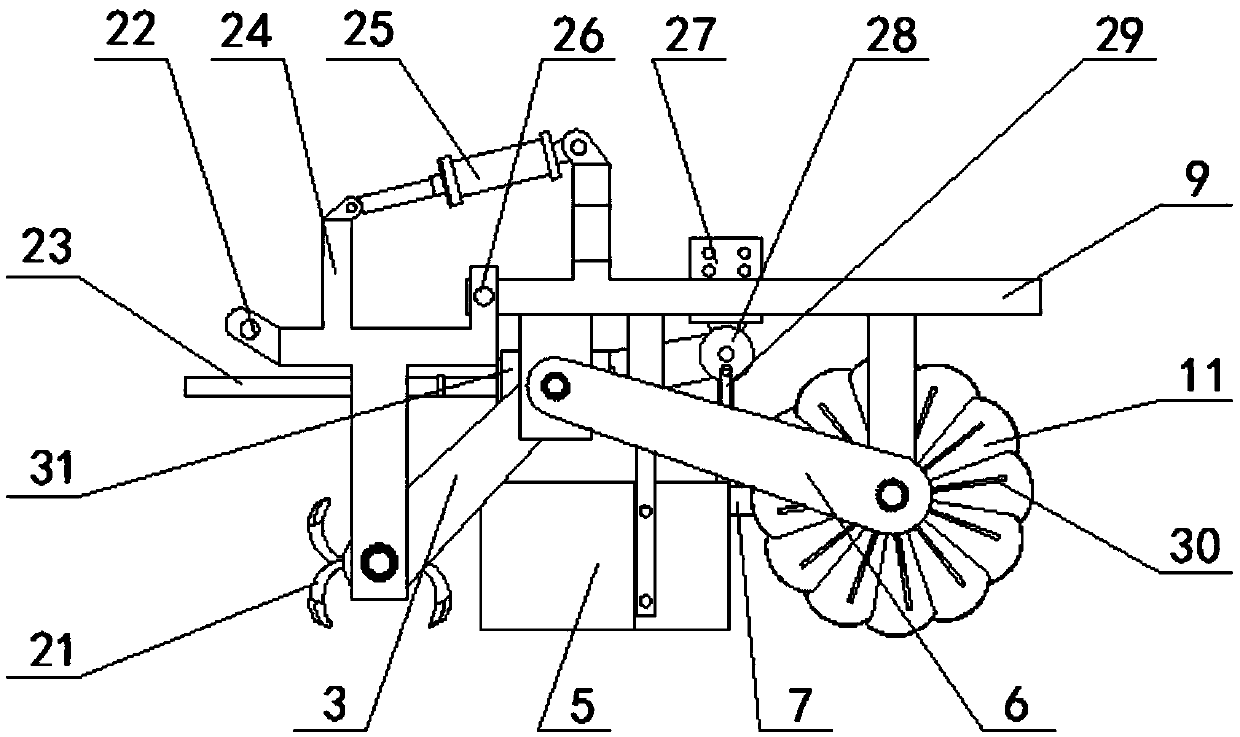

[0022] refer to figure 1 , the present invention has front and rear brackets, front frame 24 and rear frame 9 are hinged with living hinge 26, and front frame 24 is driven by a single-rod piston hydraulic cylinder 25 installed on rear frame 9 to realize going up and down around the hinge point turn. The front end of the front frame 24 is provided with a traction frame 22 and a power transmission link 23 connected with the tractor. The loosening device is installed under the front frame 24; the front end of the rear frame 9 is equipped with a power transmission device, a soil gathering device, and an eccentric wheel vibration compacting device;

[0023] refer to figure 1 , 2 , 5, the reversing gear box 31, speed reduction box 19, input drive shaft 20, output drive shaft 4 and both sides of the drive sprocket box one 3, drive sprocket box two 6 of the power transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com