Display unit dismounting device and dismounting method

A technology for disassembling devices and display devices, which is applied in the direction of hand-held tools and manufacturing tools, can solve the problems of display module damage and disassembly efficiency, and achieve the effect of improving disassembly efficiency and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

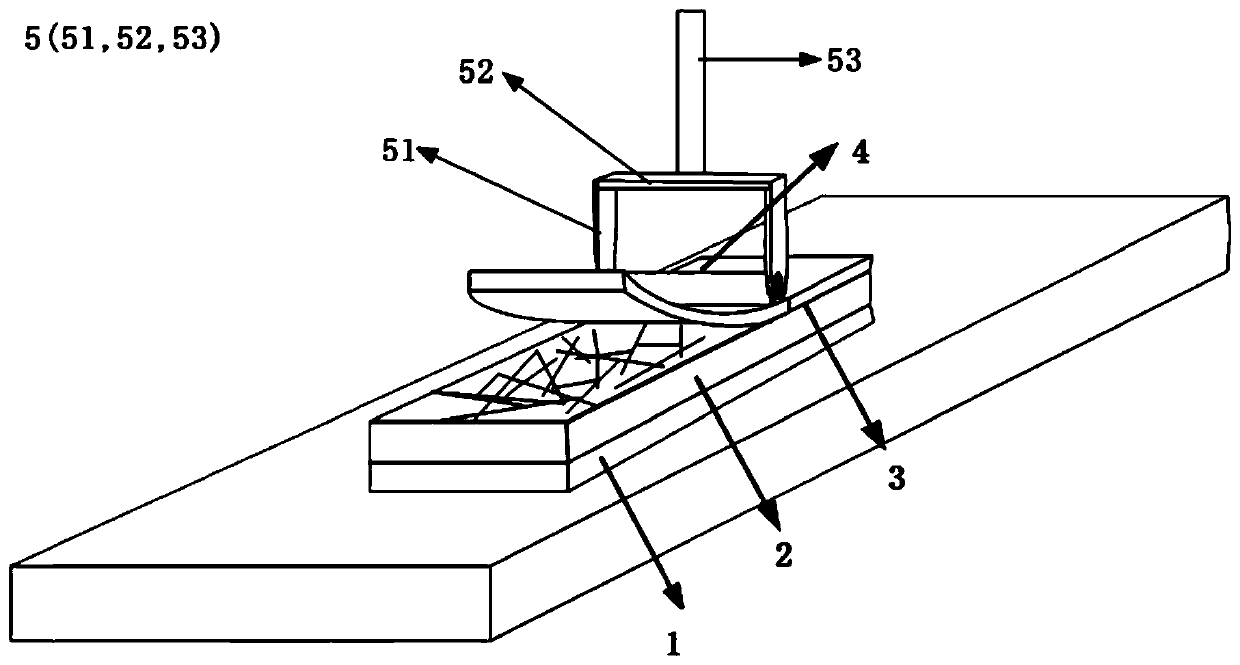

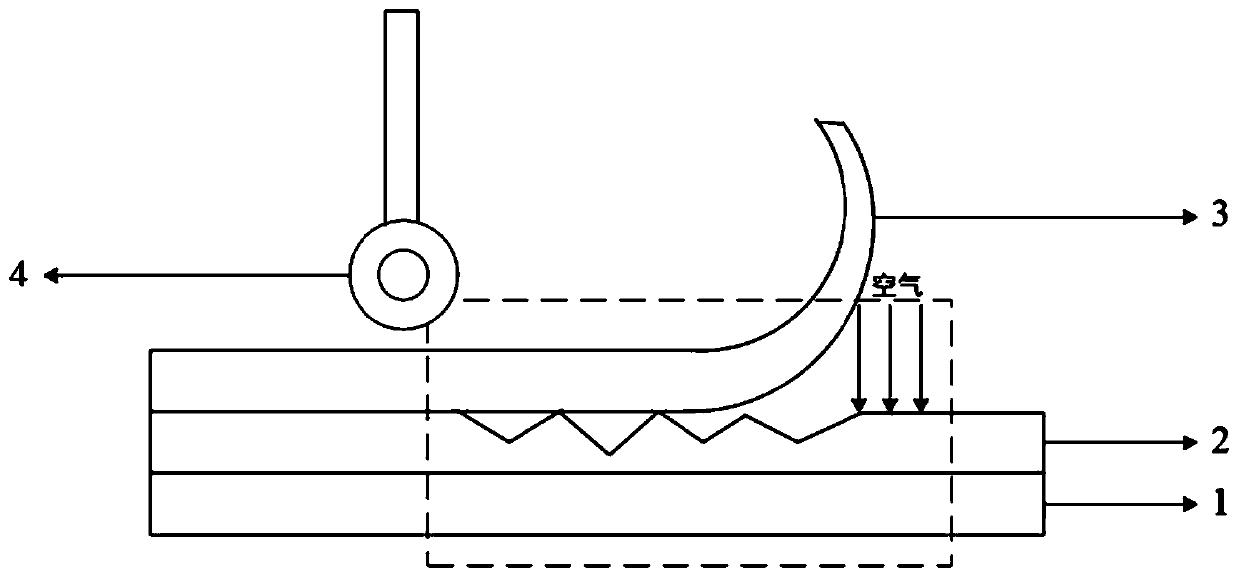

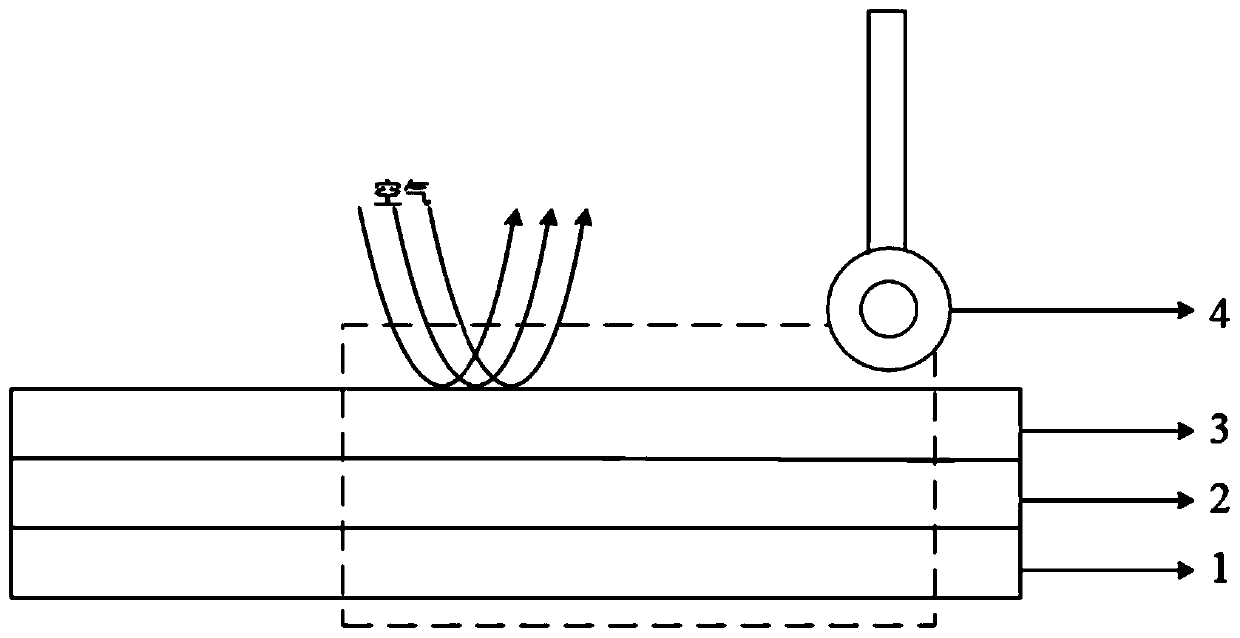

[0044] This embodiment provides a disassembly device for a display device, such as figure 1 As shown, the dismantling device includes a fixing component, a fitting component, a rolling component and a dismantling component. The display device includes a cover plate 2 and a display module 1 which are stacked. Wherein, the display module 1 is a display screen formed on a substrate, wherein the substrate may be a flexible substrate formed of materials such as polyethylene terephthalate (PET), polyimide (PI), Or non-flexible substrates formed of materials such as glass. The display screen is selected from a liquid crystal display (LCD), an organic electroluminescent display (OLED), an electroluminescent display (LED), and the like. The cover plate 2 is made of transparent glass (such as aluminosilicate glass / soda lime silicate glass). When the cover plate 2 is damaged, the display device needs to be disassembled to remove the cover plate 2 and recycle the display screen.

[00...

Embodiment 2

[0060] This embodiment provides a disassembly device for a display device. The difference between the disassembly device and the disassembly device provided in Embodiment 1 is:

[0061] The bonding layer 3 in the bonding assembly includes a bonding material layer and an adhesive layer, wherein the adhesive layer is arranged on a side surface of the bonding material layer close to the cover plate 2 for bonding the cover plate 2 and the bonding layer. material layer. The bonding material is selected from a non-adhesive material, such as polyethylene resin material; the bonding material layer can be selected from viscous glue, and the bonding material layer formed by polyethylene resin material is adhered to the cover plate 2 away from the display module by using the viscous glue. On one side of the set 1 , an adhesive layer 3 is formed, and the thickness of the adhesive layer 3 is 20% of the thickness of the cover plate 1 . The bonding layer 3 can be a single layer or a multi-l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com