A combined positioning shaft and positioning method

A positioning method and combined technology, applied in the field of combined positioning shaft and positioning, can solve the problem that the uniformity of the matching gap between the positioning shaft and the joint hole is difficult to control, it is difficult to ensure the vertical angle between the positioning shaft and the forming tool, and the metal joint is scratched. Hole matching shaft hole and other problems, to achieve the effect of good popularization and application value, good process stability and operability, avoiding direct contact and contact-type relative displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with specific examples and accompanying drawings.

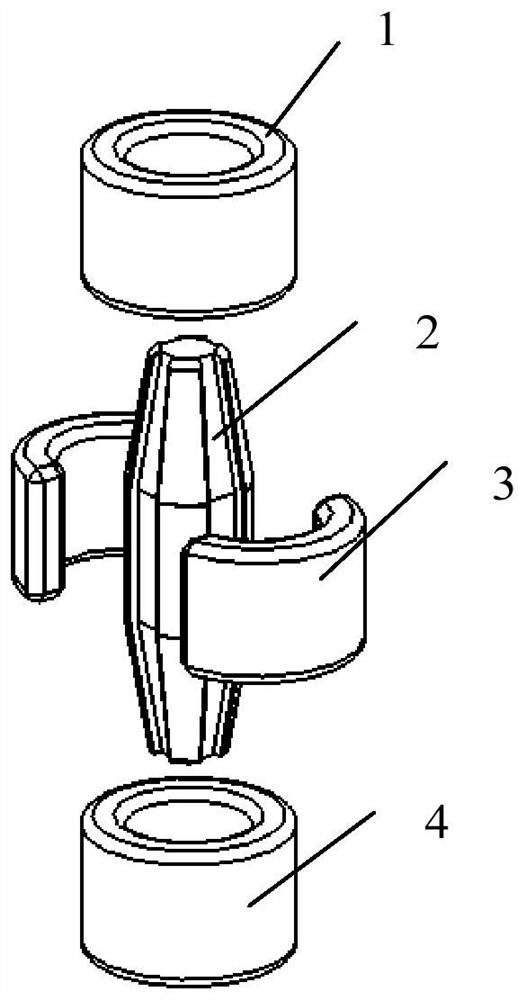

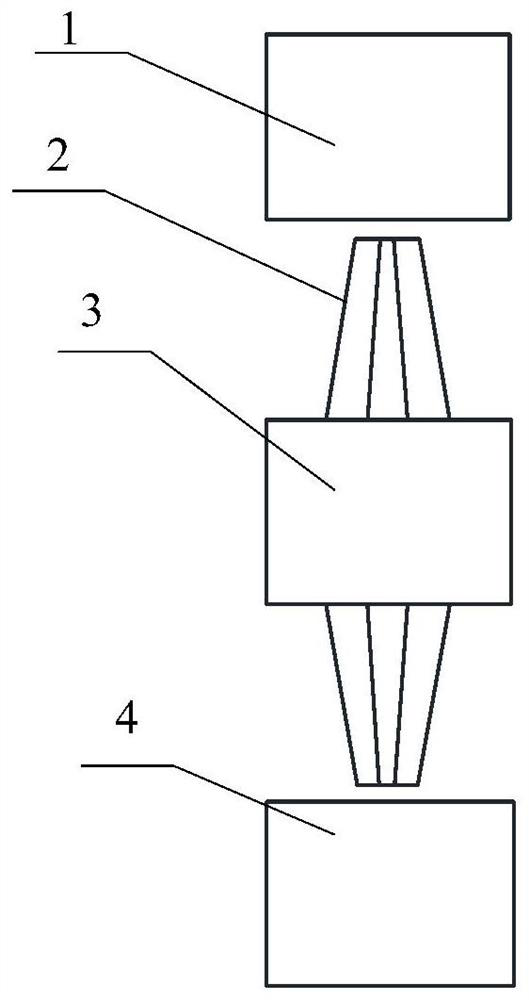

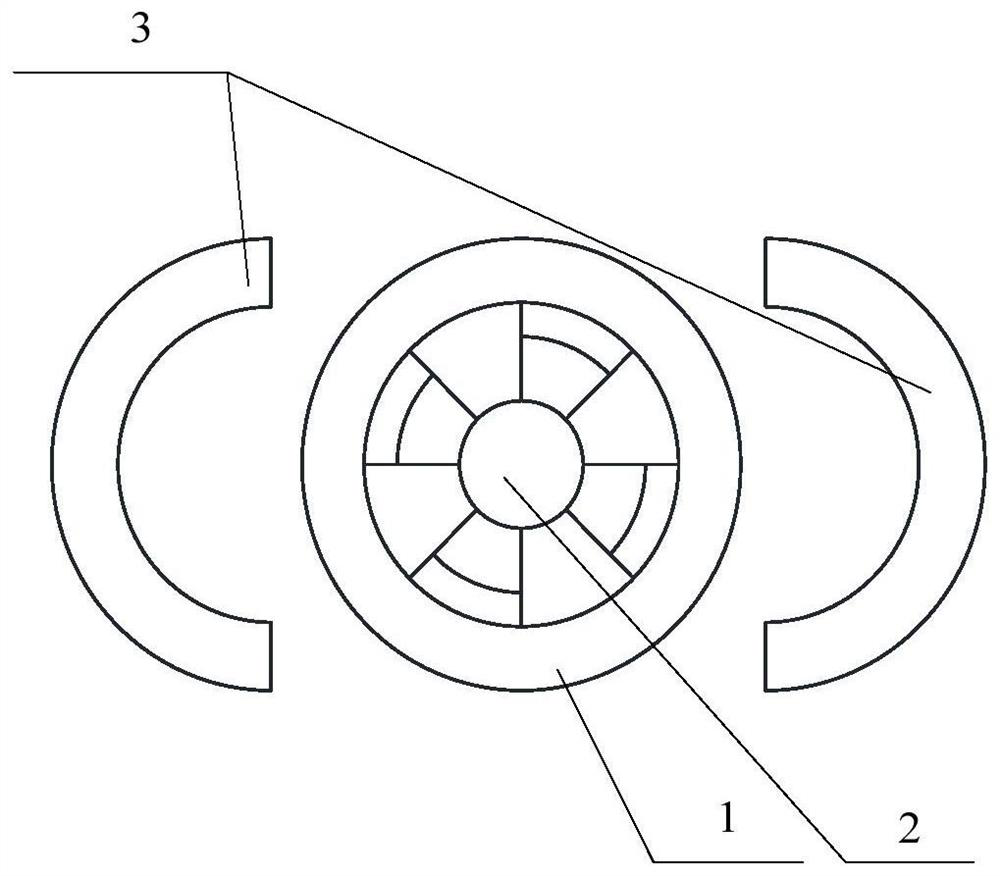

[0031] The present invention as figure 1 , 2 , 3 shown, by the upper mold shaft sleeve 1, center positioning shaft 2, split type protection sleeve 3 and the lower mold shaft sleeve 4 components. Centering axis 2 as Figure 4 , 5, the middle part is a cylinder 22, the two ends are conical 21, 23 jujube stone shape, the middle cylinder 22 of the central positioning shaft 2 is interference fit with the split type protection sleeve 3, and the upper and lower ends 21, 23 are respectively connected with the upper mold The axle sleeve 1 is matched with the lower die axle sleeve 4.

[0032] The split-type protective bushing 3 is bonded and installed in the shaft hole, the upper die bushing 1 and the lower die bushing 4 are respectively installed in the upper and lower molds, the central positioning shaft 2 is placed in the split-type protective bushing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com