Heavy truck electric control mechanical disc type brake

A technology for heavy-duty vehicles and mechanical discs. It is applied to brake types, axial brakes, and mechanical equipment. It can solve the problems of small contact area of friction plates, difficult maintenance, and eccentric wear. The effect of wiring harness simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

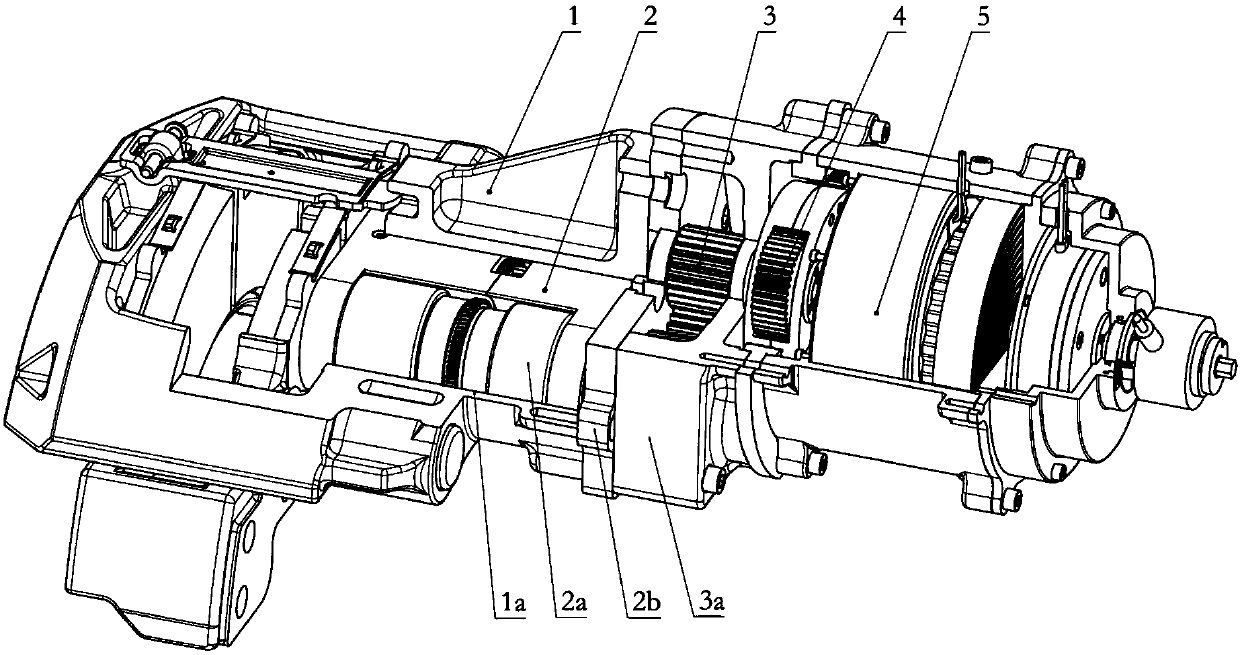

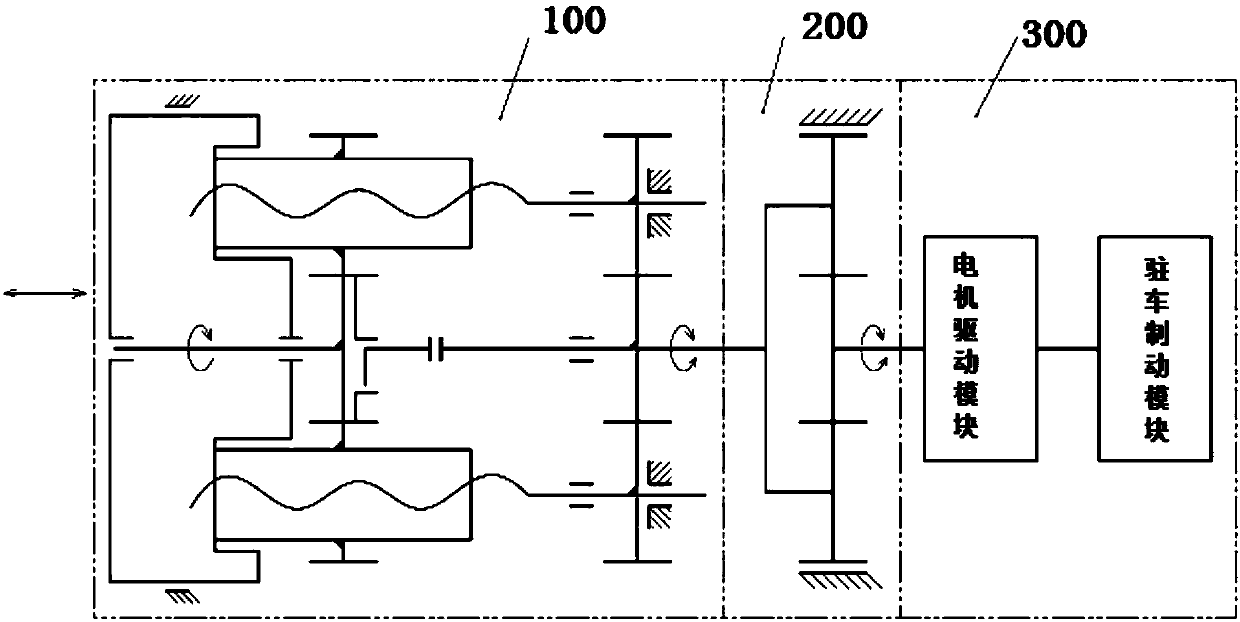

[0024] combine Figure 1 to Figure 2 , a kind of heavy-duty vehicle electromechanical disc brake of the present invention comprises: brake caliper (1), thrust actuator (2), power distribution mechanism (3), planetary reduction mechanism (4), power output mechanism (5 ); from the perspective of the power and transmission system, it includes a thrust execution module (100), a planetary reduction module (200), and a power supply module (300).

[0025] In a specific embodiment, the brake caliper (1) is floatingly fixed on a fixed bracket, which is generally fixedly connected to the drive axle tube, and the brake caliper (1) has a chute (1a), which performs The push rod (2a) of the mechanism (2) cooperates, and the push rod (2a) can freely slide axially in the slide groove (1a). The push rod (2a) is pushed by its internal ball screw pair to brake. The power distribution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com