Movable construction waste recycling treatment equipment and application method

A technology for recycling and processing construction waste, which is applied to grain processing, lighting and heating equipment, chemical instruments and methods, etc., can solve the problems that construction waste cannot be applied and cannot meet the needs of mobile construction waste recycling and processing, and can improve the quality level, Improve crushing quality and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

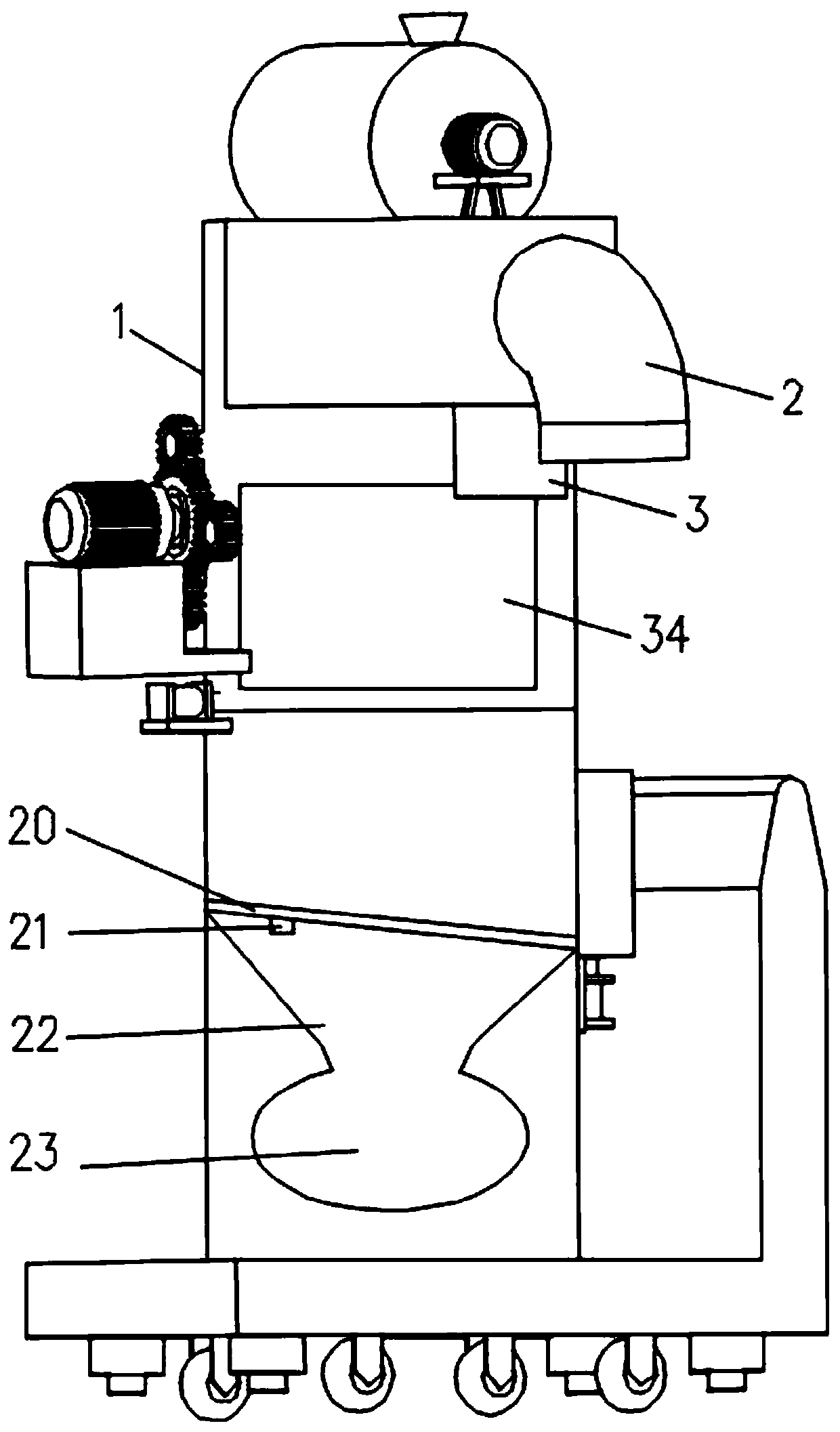

[0054] as attached figure 1 As shown, a mobile construction waste recycling and processing equipment includes a cabinet 1, a drying device, a separating device, a metal removing device, a crushing device and a collection box.

[0055] The drying device is arranged at the upper end of the cabinet 1, the separation device is arranged at the lower end of the drying device, the metal removal device is arranged at the lower end of the separation device, and the crushing device is arranged at the metal removal device lower end.

[0056] The collection box includes a plastic collection box 2, a wood block collection box 3 and a concrete collection box 23.

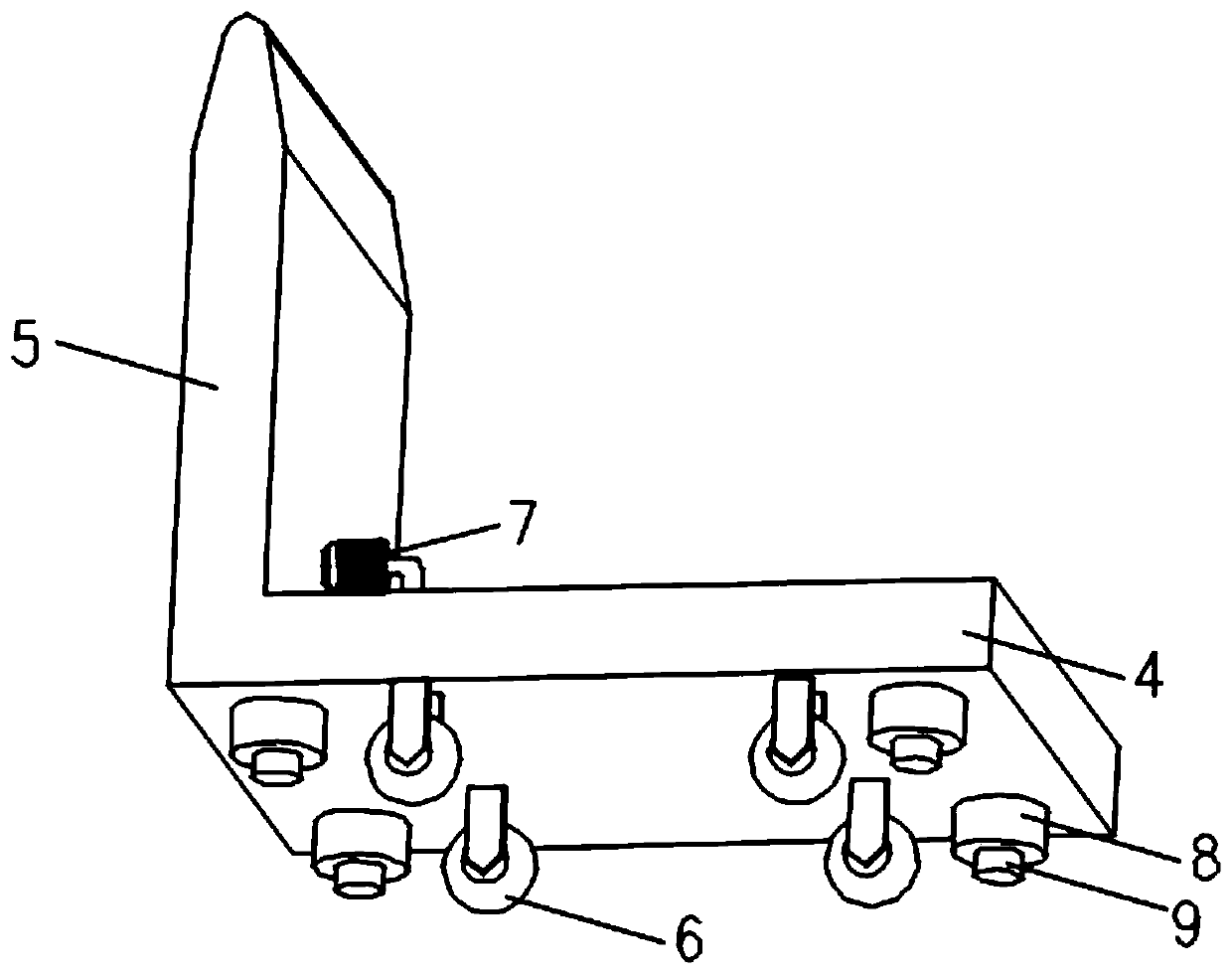

[0057] as attached figure 2 As shown, the lower end of the chassis 1 is fixedly connected with a base 4, one side of the base 4 is fixedly connected with a push frame 5, and the lower end of the base 4 is provided with four rollers 6, and the rollers 6 are used to move the processing equipment. The processing equipment can be ...

Embodiment 2

[0087] Based on the above-mentioned embodiment 1, the similarities will not be repeated, and the difference is that, as attached Figure 8 As shown, the cleaning device is used to clean up the metal impurities adsorbed on the electromagnetic roller 13, and the cleaning device includes a pushing board 36, a cleaning board 35 and a first hydraulic cylinder 37; the cleaning board 35 includes a first cleaning board and The second cleaning board, the first cleaning board and the second cleaning board are fixed on both sides of the cabinet 1 in a foldable manner through hinged rods 39; when in the non-cleaning state, the first cleaning board and the second cleaning board are folded into the cabinet 1. Inner wall: In the cleaning state, the first cleaning board and the second cleaning board are propped up by the hinge rod 39 and overlap each other to form a horizontal board.

[0088] The miscellaneous plate 36 is arranged on the opposite side of the metal removal outlet 15, installed...

Embodiment 3

[0096] Based on the above embodiments, a method for using mobile construction waste recycling and processing equipment includes the following steps:

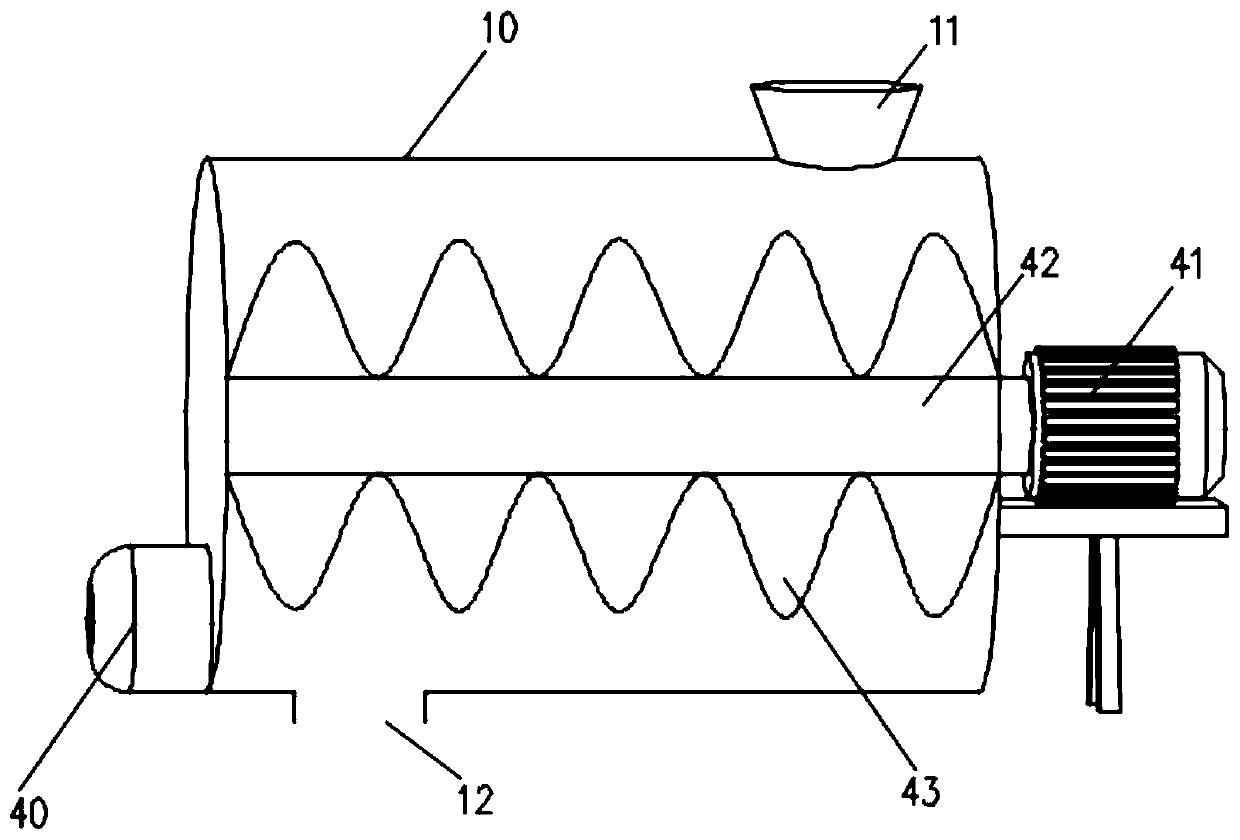

[0097] S1. The operator moves the equipment to the designated location, fills the construction waste into the hopper 11, the construction waste is fed through the hopper 11, and enters the drying device, which dries it, and the electric heater 40 Heating the electric heating tube to increase the temperature in the drying box 10;

[0098] S2. After step S1, the dried construction waste enters the separation device through the first outlet 12, and the separation device separates the plastic and wood blocks mixed therein, and the blower separates the plastic and wood blocks from the construction waste by wind force , blowing to an end of the separating box 44, while the rotary wheel 47 rotates and plastics are brought into the plastic collection box 2, and the wood block is subjected to gravity, and enters the wood block collection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com