Optimization process for sterilizing non-intrusive liquid product

A non-invasive, liquid technology, applied in ultra-high pressure food processing, food preservation, food hydrolysis, etc., can solve the problems of unsuitable industrial production, membrane clogging, and membrane filtration failure, so as to reduce energy consumption and extend the shelf life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

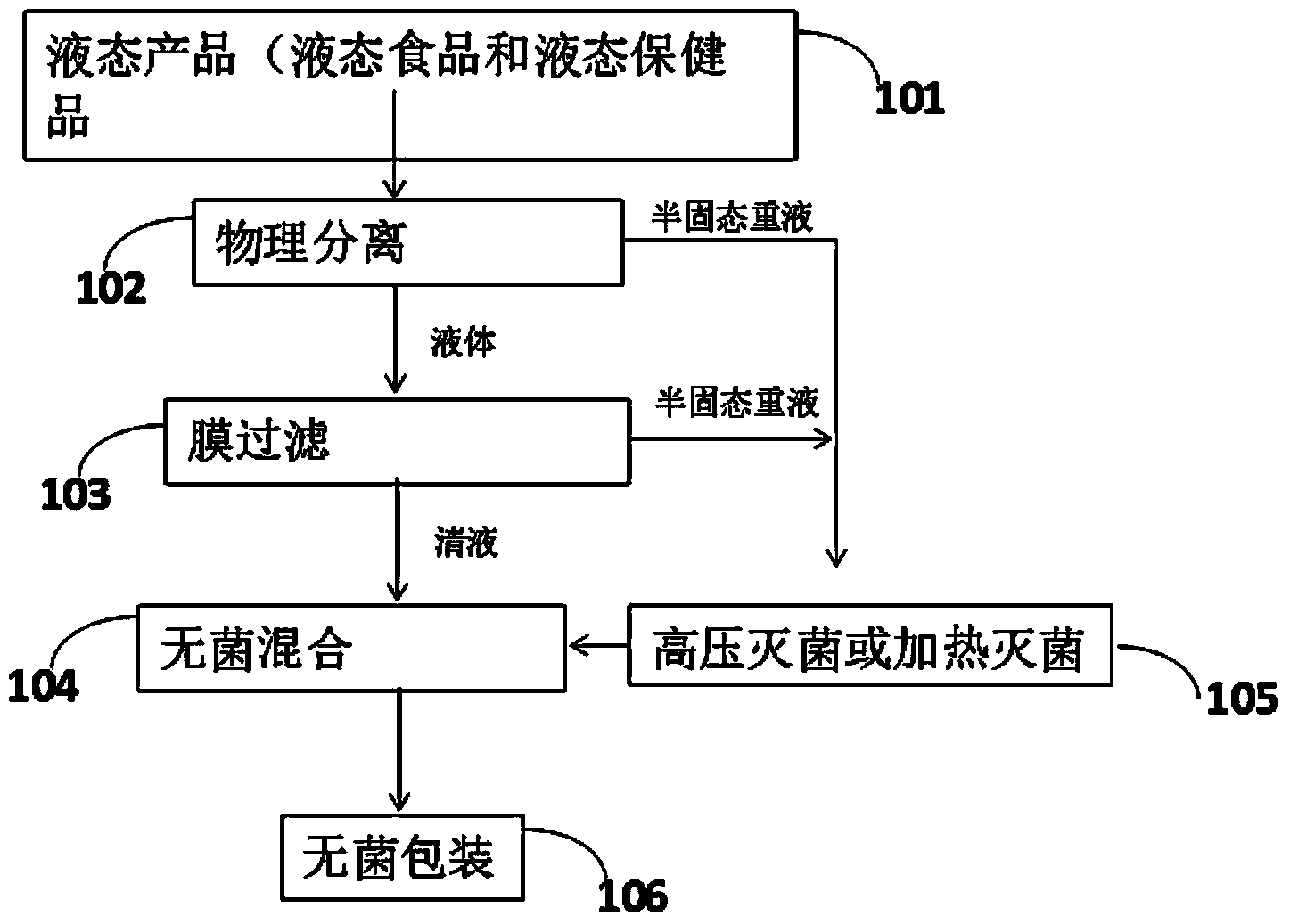

[0038] Such as figure 1 As shown, this embodiment includes the following steps:

[0039] Step 1. Filter 1500L of orange extract through a plate and frame filter at a constant pressure of 0.10-0.2MPa, the filtrate is 1470L, and the average flow rate of the filtrate is 485-520L / hour; the filtrate is centrifuged through a horizontal sedimentation centrifuge to obtain 1470L The supernatant liquid and 2.5kg semi-solid, according to the density of the supernatant liquid is 1.0-1.1kg / L, the proportion of semi-solid heavy liquid is 0.15-0.17%wt.

[0040] The specific main operating parameters of step 1 are as follows: feed pump speed regulation 350-380r / min; drum speed 3000-3300r / min; differential speed 12-20r / min. The total bacterial count TPC (total colony count) in the supernatant after centrifugation was measured to be 40,000 / g, and the particle size of the semi-solid heavy liquid after separation was less than or equal to 10 μm.

[0041] Step 2, further filtering the clear liqu...

Embodiment 2

[0049] This embodiment includes the following steps:

[0050] Step 1. Centrifuge 3000L of purple sweet potato extract to obtain 2980L of clear liquid and 37kg of semi-solid. According to the density of the clear liquid of 1.0-1.1kg / L, the proportion of semi-solid heavy liquid separated is 1.1-1.2%wt ..

[0051] The specific main operating parameters of step 1 are as follows: feed pump speed adjustment: 360-420r / min; drum speed 3100-3300r / min; differential speed 10-15r / min after centrifugation, the total amount of bacteria in the clear liquid is measured by TPC The obtained value is 156000 / g, and the particle size of the semi-solid heavy liquid part after separation is less than or equal to 10 μm.

[0052] After the above separation, a 10MWCO to 1.0μm microfiltration membrane filtration system is compressed and filtered under the condition of an inlet pressure of 6.896-1034.483KPa to obtain about 2975L of sterilized purple potato juice.

[0053] Step 2: Filter the above-menti...

Embodiment 3

[0060] This embodiment includes the following steps:

[0061] Step 1. 55kg of spinach extract is naturally settled, and the supernatant is centrifuged in a low-speed centrifuge at a speed of 5000r / min to separate 54.2kg of liquid and 0.8kg of semi-solid, and the total amount of bacteria in the clear liquid after centrifugation TPC was measured as 42,600 / g, and the proportion of semi-solid heavy liquid was 1.4%wt.

[0062] The liquid obtained after the above separation was further filtered through a microfiltration membrane filter, the inlet pressure was 0.25 MPa, and the membrane pore diameter was 0.8 μm to obtain 53.7 kg of clarified spinach juice.

[0063] Step 2, compressing and filtering the above spinach juice through a 10MWCO to 1.0 μm microfiltration membrane filtration system under the condition of an inlet pressure of 6.896-1034.483KPa.

[0064] After the above-mentioned membrane filtration, the total amount of bacteria in the liquid TPC was measured to be 50 / g, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com