Powder metallurgy sintering furnace and sintering process thereof

A powder metallurgy, sintering furnace technology, applied in separation methods, human health protection, dispersion particle separation, etc., to achieve the effect of increasing the discharge rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

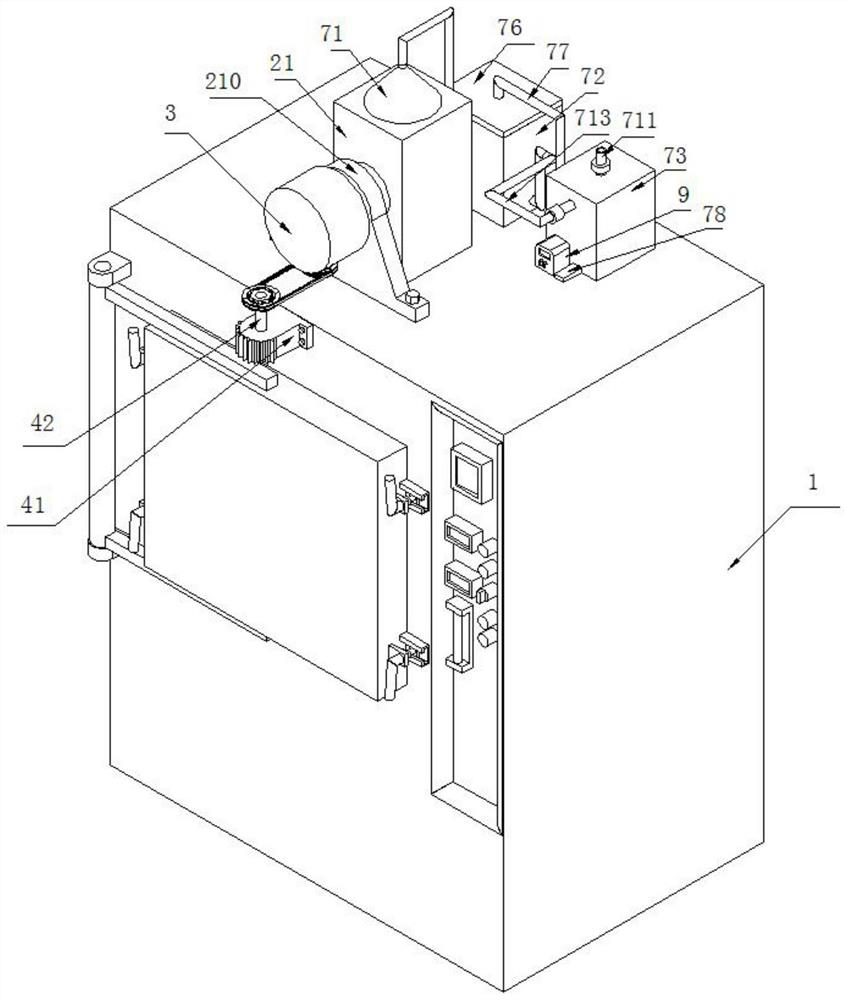

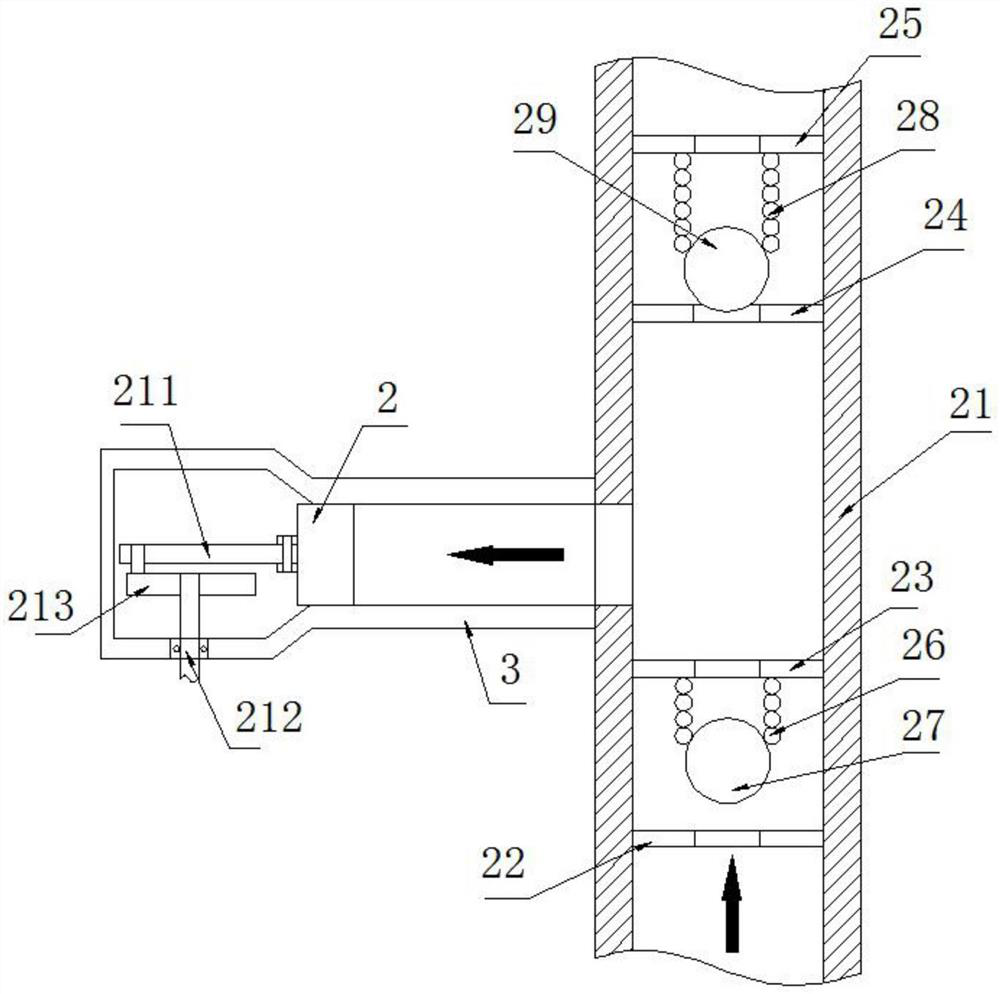

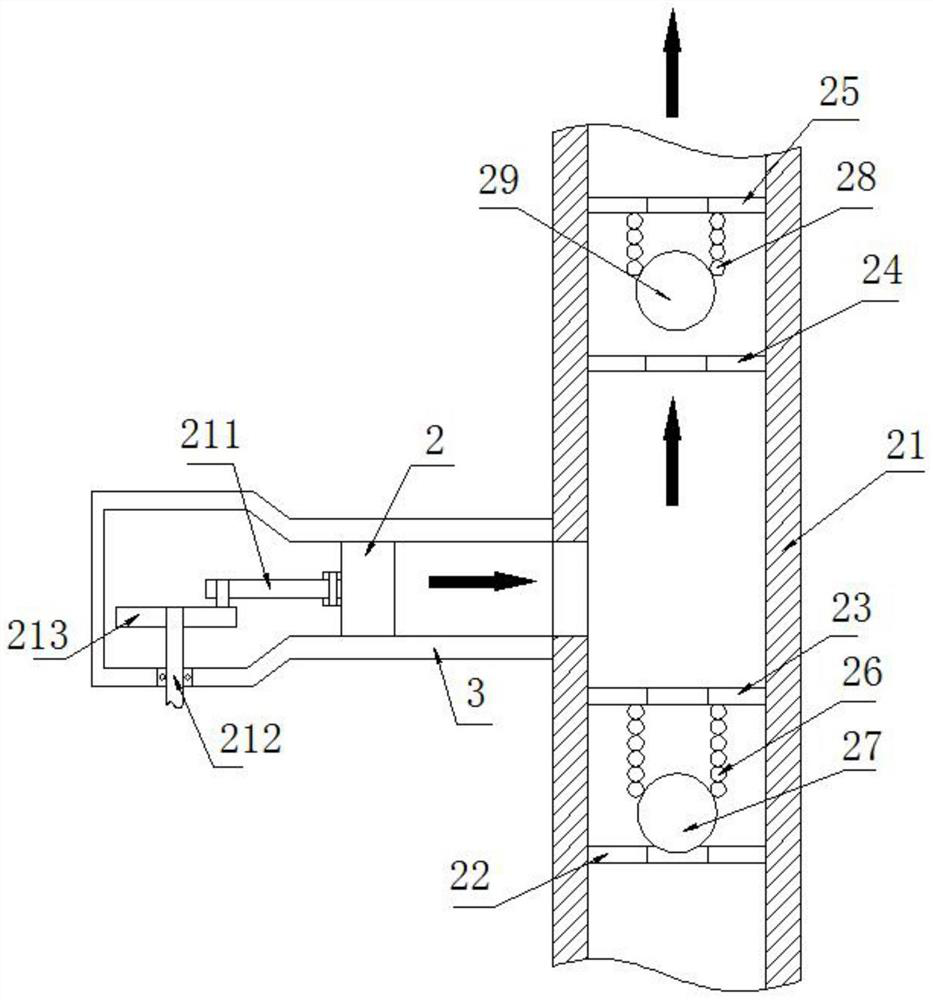

[0054] refer to Figure 1-7 , a powder metallurgy sintering furnace and its sintering process, the process comprising the following steps:

[0055] S1, raw material preparation, three powders of iron, copper, aluminum, titanium, nickel, tungsten and alumina are selected as powder raw materials;

[0056] S2, pour the selected powder raw material into the mixer equipment and mix thoroughly;

[0057] S3, filling the mixed raw material powder into the mold for compression molding;

[0058] S4, the compression-molded product is loaded into the sintering cavity of the sintering furnace equipment 1. The sintering furnace equipment 1 further adop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com